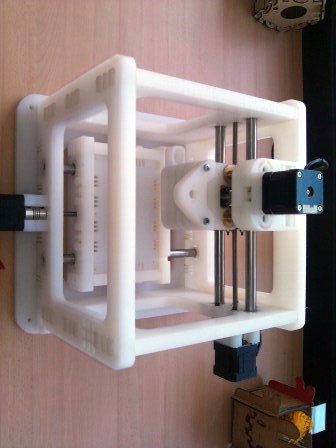

| Week14 | Mechanical design, machine design |

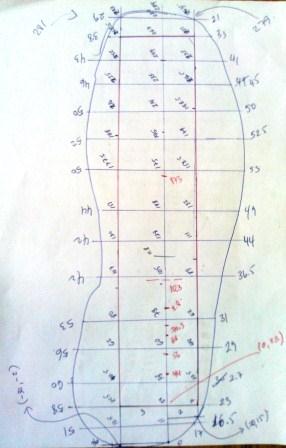

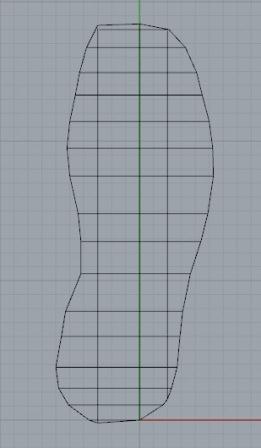

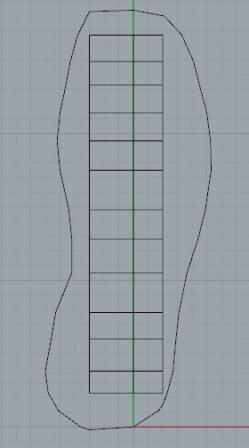

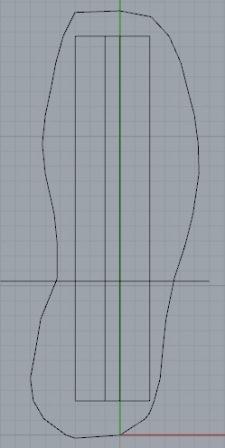

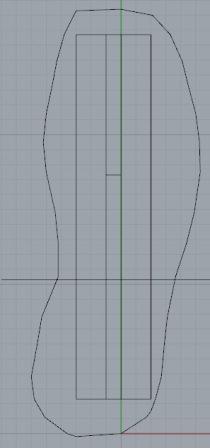

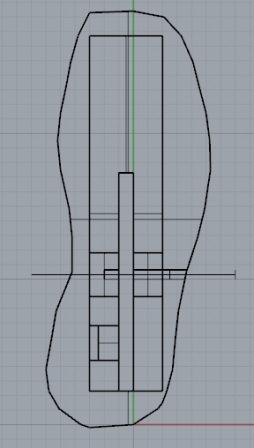

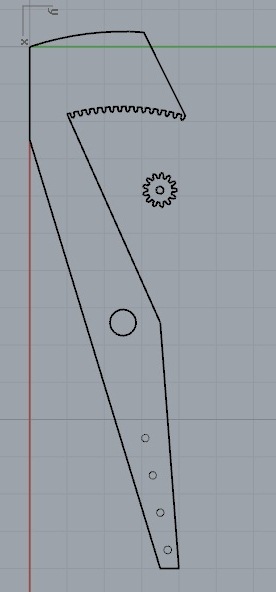

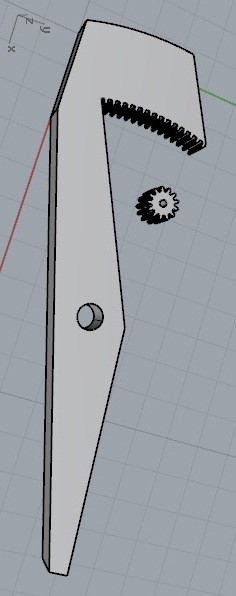

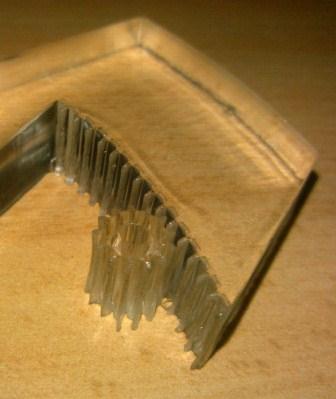

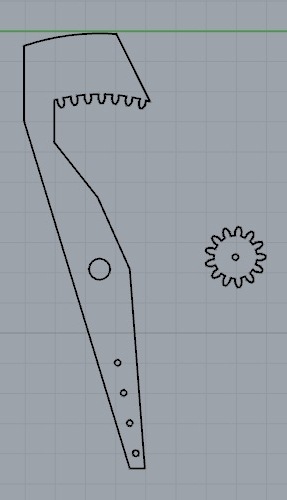

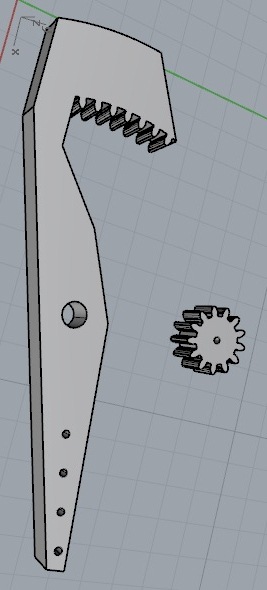

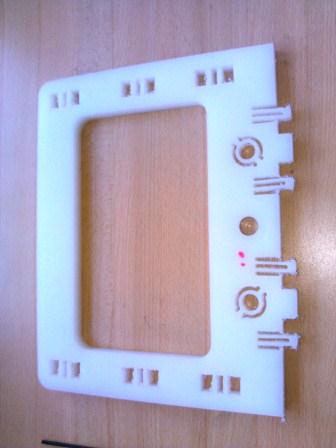

In the image shown is the template from which the data were taken ... |  ...to draw the template model using Rhinoceros software. |  |  |

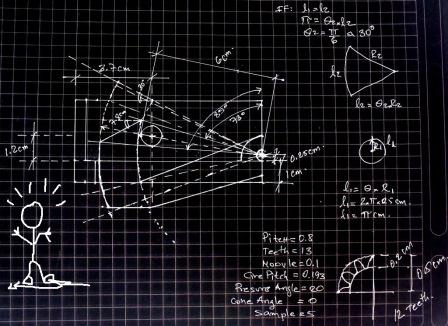

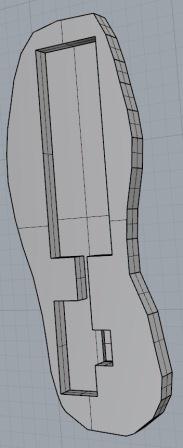

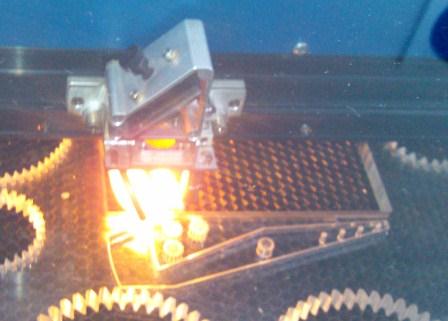

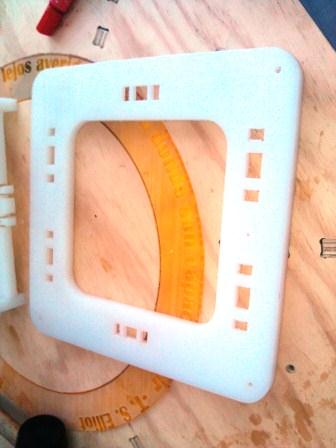

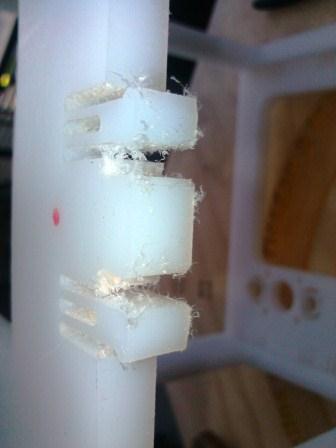

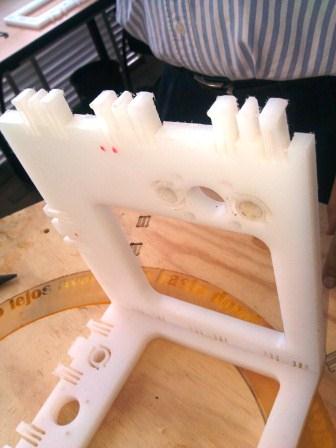

|  |  The bottom where the lever shaft, generator and slot planca will fit... |  Top that will contain support for the springs ... |

|  |  |  |

|  |  |  |

|  |

|  |

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |