Molding and casting...

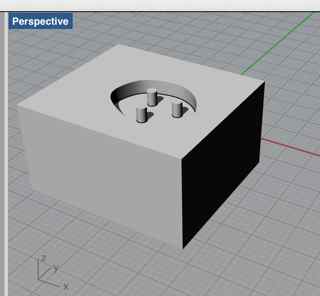

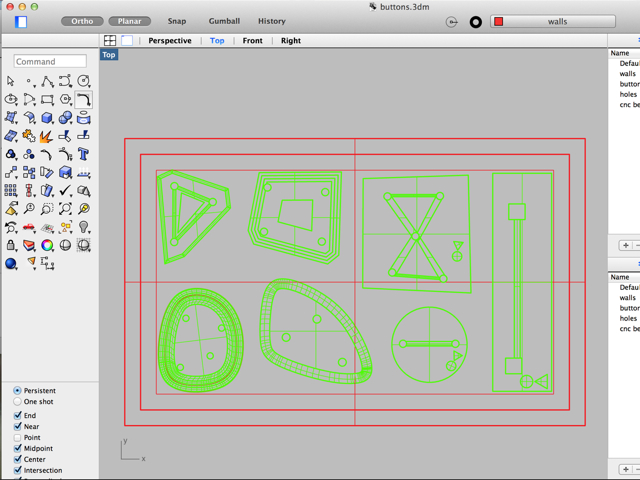

For this assignment because the silicon did not arrive on time for the assignment I decided to improvise which was clearly a bad idea. Here is what I did: I designed the molds in Rhino

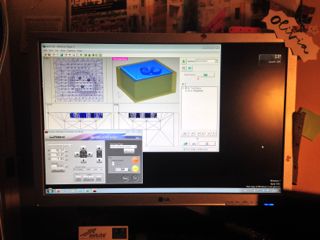

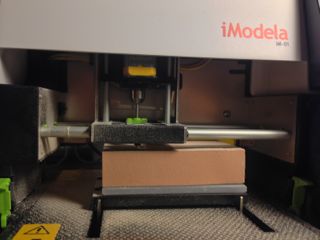

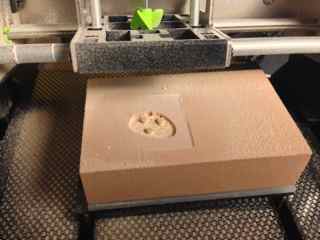

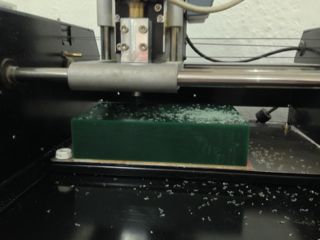

and cnc'ed them using the iModela

evrything was so easy we really enjoyed this part. For the casting because we only had resin to use, we casted the resin thinking it wasn't a bad idea but it clearly was. Although the proportion was calculated so that it wouldn't be that stiff when setting down, the resin was too hard to be removed from the modelboard.

I will try again using the positive mold to make a negative part of silicon to then cast the resin or plastic into it.. :)

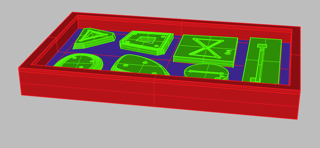

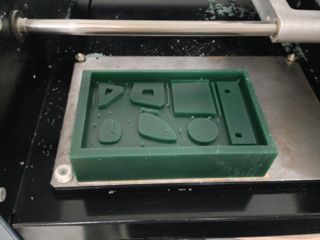

OK so here I am in Barcelona Lab, with a better [larger] design that fits in the Roland Modela. The drawing was teaked at the last minute to fit nicely into the wax given by Luciano [the one I got was 148 x 94mm]

Still in the "button" groove but more and larger buttons to be made..

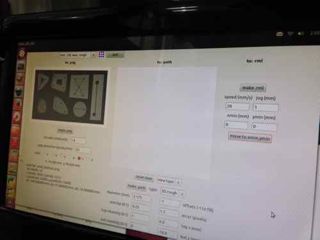

The Modela milling machine is used for milling the wax block Exporting the file from rhino, as an stl file, and using Fab Modules for the settings, I managed to get the machine set up.

Similar to the pcb boards, the wax has a roughing and finishing process whereby the tool tips need changing.

OK.. Time for mixing the mix and pour the liquid rubber to make the mold. I used the Smooth On [http://www.smooth-on.com/].

There are two parts [A + B] which need to be mixed equally in a plastic cup wearing gloves. I was later [too late!!] being advised that the gesture for the mixing needs to be circular and fast. I thought everything was wrong cause lots of bubbles started rising up in the surface once I poured the mix in the mold.

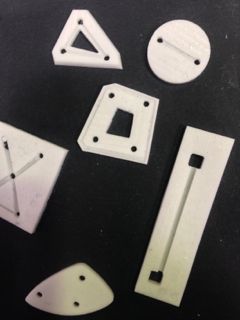

I used a screwdriver with a flat edge to pull the casted silicon out of the cnc-ed wax mold.

Here is a useful tip: The outter walls of the wax need to be angled not only for getting a better finish but also for the casted rubber to come out easier.

@$%$&%&*(*!) I should have made sure that the silicon would set nicely into the button holes. The air prevented the silicon to set in the holes so I have to re do this otherwise I'll have buttons with no holes

Using the Smooth Cast 305 that was available in the Fab Lab Barcelona, I mixed the Part A, Part B equal amounts into a plastic cup using gloves, and left it to dry for a couple of hours. Did not need that much time but I was doing something else at the time.

The drawing can be found here.