Computer Comtrolled Machining...

For this assignment I have decided to make a shelving unit for our kitchen to keep everything more tidy.

This is how the space looks at the moment so i have measured up this corner, as well as the maximum height of the things I would like to put in each shelve.

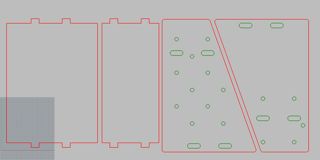

Here is the design I made.

It consists of 4 parts, 2 shelves and 2 side parts. The material used is 18mm plywood. The oval shapes are where the pieves would fit together. because the male is 18mm I made the female [oval shape] a tiny bit narrower to make sure the parts would fit perfectly and won't be loose.

The holes are there only for any extra add ons I may wish to do later on i.e. hooks. There was no need to make holes in both the side parts but should it be moved somewhere else, the holes may become handy.

The corners are chamfered to get a nicer result.

There are 2 layers, the red one is for the cutting tool [6mm] to cut on the outter part of the line thus keeping the dimensions needed. The green one is for cutting on the inner part of the shapes using a 3mm tool.

I used a 6mm tool so the design will not be altered after it gets cnc'ed: the holes are of a 13mm diameter so this should be more than enough for the 3mm tool to cut without altering the final holes sizes.

I have cnc-ed the furniture at a 2400 x 600 x 18mm spruce plywood sheet in the AXYZ cnc milling machine. The design is made in Rhino and is exported as a dxf file. It is then imported into Artcam which is what we use to drive the machine, in order to make the toolpaths. in this case only two toolpaths are required.

The drawing can be found here.