3D scanning and printing...

For this assignment Alexandros [Fab Lab Cardiff] and I decided to replicate a traditional turkish instrument which is called Ney. It is a flute based instrument with a mouthpiece. We measured, designed and 3d printed the body and mouthpiece and we put them together. I designed and 3d printed the mouthpiece , Alexandros designed and 3d printed the body.

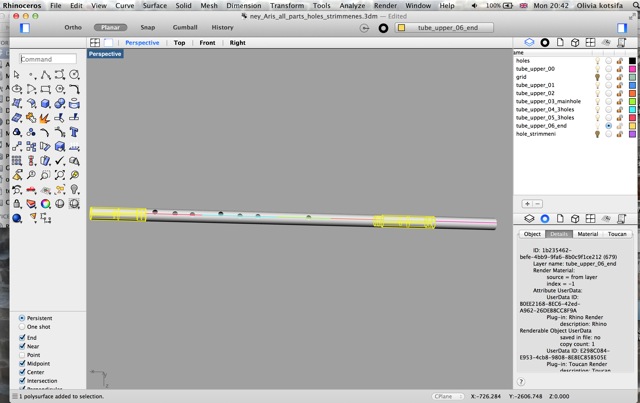

in order for the instrument to be 3d printed we had to design it in such a way for it to fit in the 3d printer. Each part was less than 150mm so we had 7 parts altogether.

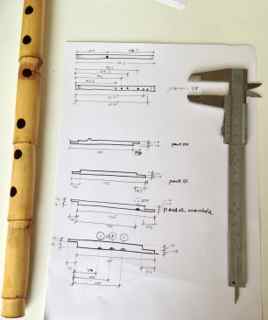

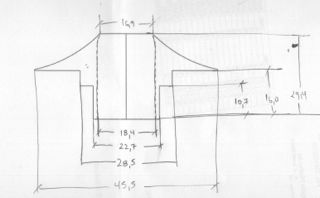

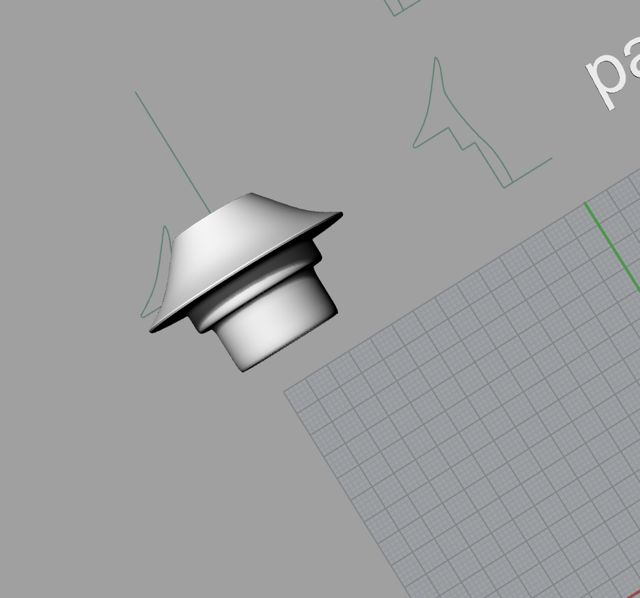

...and we measured the mouthpiece in order to design in in Rhinoceros

3d printing was easy, we have tried it before so we found it easy to make.. Here are the 2 parts of the instrument:

...and the mouthpiece also fit in the original instrument since the dimensions were taken from that:

The 3d printed mouthpiece can also be fitted onto the original Ney instrument.

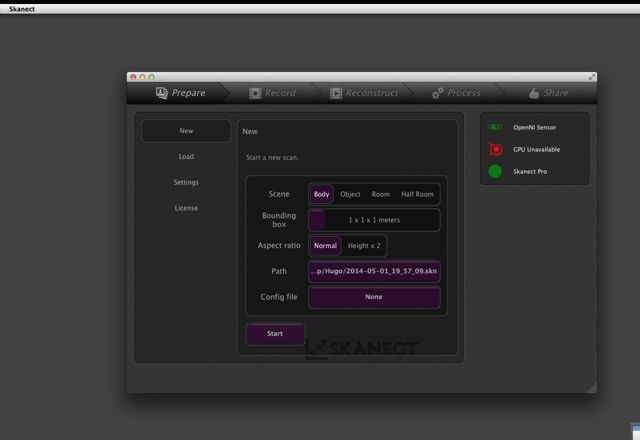

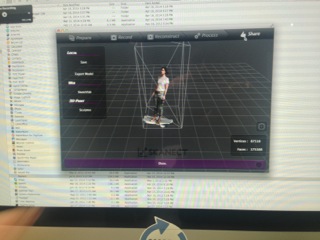

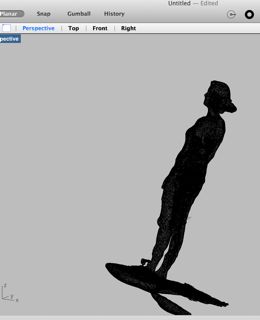

For the 3d scanning I used the kinect and with the help of another person I managed to get a personal scan.

Scanning could be easier if the lighting was good and even. Also for next time, to make the scanning easier I would start from the bottom upwards and make sure there is enough space to move around.

I used the Kinect for xBox 360 and Skanect in order to make the meshes. The file was then exported as an .obj file with not many broken meshes since Skanect can fix most of the holes created during the scanning.

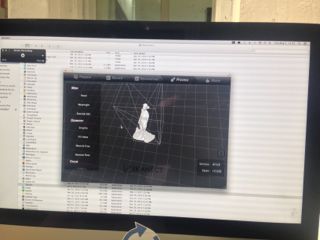

The file was then imported into Rhino and with a very little effort in rhino and MeshLab the stl file is ready! I will 3d print this if there is time later but need to make sure I get rid of the scanned floor around the feet of the scanned object.

The 3d printing drawing can be found here.