This week's summary

This week's exercise was to design and build a mold

and then use the mold to make a final product. My project is based

on the college logo and the goal is to make small chocolate bars

in the shape of the logo.

Tools and References

Inkscape was the primary tool used for the design.

VCarve Pro Trial Edition 7.0 was used to simulate the design.

Design Notes

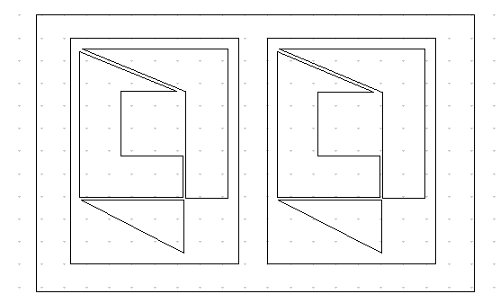

A .png file of the official logo was imported

into Inkscape.

The image was scaled to ensure that a 1/32 inch bit would fit

through the smallest element of the design (the diagonal line).

The file was saved as a .pdf and opened up in VCarve Pro at the

Shopbot.

Logo design view from VCarve pro

Design Simulation

The original plan was to use the Modela milling

machine, but we migrated to the Shopbot since the Modela was

occupied.

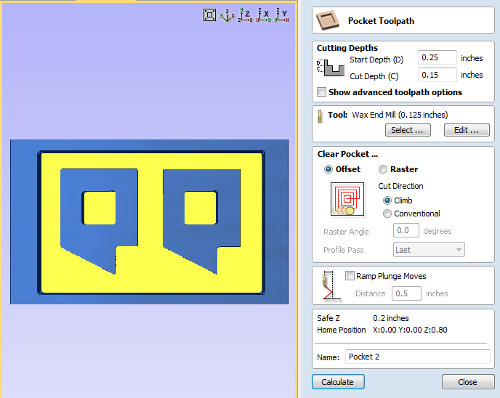

VCarve Pro Trial Edition 7.0 is an excellent tool to simulate the

design.

Several iterations were required to get a good bitmap image. It is

important to get a source file with the image. Much time was

wasted with poor quality images.

Mold Tool Fabrication Notes

The mold tool was fabricated using the Shopbot

milling machine.

The material was 6 x 3.5 x 1.25 inch machineable wax.

The material was secured in position using double sided tape on

the base and hot glue around the edges.

The material was cut using 4 separate pockets (waste material was

removed and recycled after each profile cut):

- Pocket 1 was 0.25 inch deep with a 1/8 inch end mill and

reflected the top edge of the letters in the logo.

- Pocket 2 was a further 0.15 inches deep with a 1/8 inch end mill and routed the

letters on the logo (see picture).

- Pocket 3 was a further 0.15 inches deep with a 1/8 inch end mill and

routed the base.

-

Pocket 4 was a finishing cut with a 1/32 inch end mill and finished

the entire profile.

Pocket 2 simulated on Vcarve Pro

The Outcome

The job ran well and the outcome was very good.

Mold Tool after Shopbot

Building the Mold

The material used was Smooth On SmoothSil 940 food

safe silicone rubber.

This is a 2 part mix, 90%/10% by weight.

The directions recommend 3 minutes mix, we mixed for approximately

10 minutes to get the mix correct.

The mixing process was quite difficult and took a lot of effort

with a wooden tongue depressor.

The pour was done slowly due to the high viscosity of the mix.

The pour was done in one corner location and the material slowly

moved across the mold.

Some material flowed over the edge, this was a significant benefit

to provide a grip for demolding.

The tool and material was heated for 3 hours at 200 degrees F. It

was then left overnight (for convenience).

The demolding was extremely easy and was completed in 30

seconds. The result was excellent.

Tool and Mold after demolding

Molding the Chocolate

The chocolate needs to be "double boiled" for

melting. I used a coffee cup inside a pot of heating water.

Gentle heat should be applied to melt the chocolate, and frequent

stirring is required.

I tried a number of pour methods. I tried a syringe but the

viscosity of the chocolate does not allow that to work well.

The best method was simply to gravity pour from a spoon.

The corners are difficult. I used a wooden toothpick to "help" the

chocolate run into the corners.

I did not use a release aid but I will try more attempts with

Lecithin liquid.

I also intend to try different types of chocolate.

There is no process waste since I have 3 kids who are readily

available to consume material!

Chocolate bars from mold (further experimentation

planned to improve finish).