This week's summary

This week's exercise was to modify an existing board design and

then to fabricate and assemble the board.

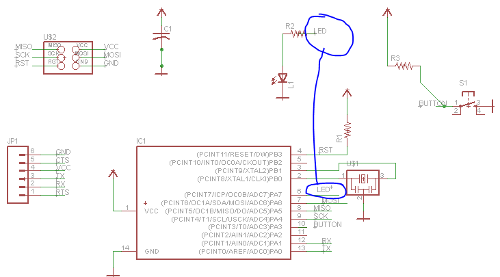

The base board design is the Fab Lab Echo Board. The additions are

a Button, a LED and the associated components.

Tools and References

Eagle Software 6.5.0 was the primary tool used for

the design. A version of this is available as a free download.

Eagle includes many component libraries with the download, but

additional components need to be downloaded for this specific

design.

The "base design" schematics (.sch) and board (.brd) files were

imported into Eagle (from the Fab Academy archives).

Design Notes

Parts were added in the schematics view using the

"Add" button on the left hand toolbar.

Connections were made in the schematics using a combination of

mouse clicks and NET names (example of NET names is "LED" net

highlighted in schematics below).

As connections were made, I switched back and forth to the board

view to ensure traces were being created.

The parts and traces appeared on the bottom left of the board

view (off the board).

Switching to board view, the parts were positioned inside the

board outline.

Autoroute was run (Tools, Autorouter) as a preliminary routing.

A number of traces were cleaned up using the Ripup and Route

buttons on the left hand toolbar.

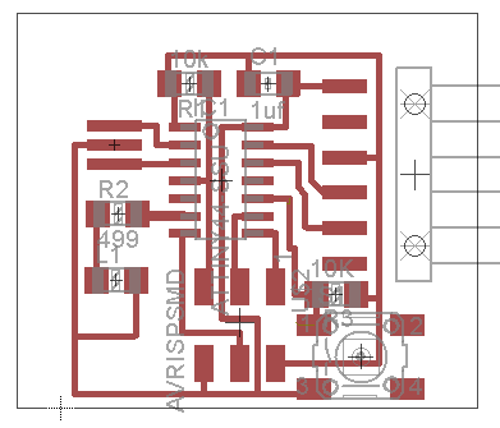

Board layout (upper) and schematics (lower)

Design Checks

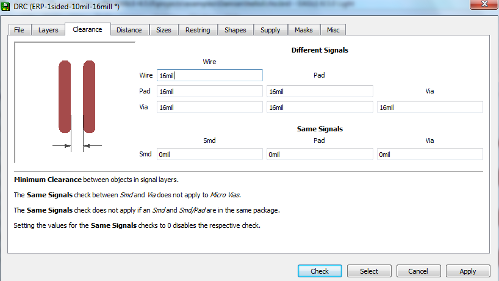

DRC was run with clearances set at 16 mils on Tools, DRC,

Clearance tab as shown below (to allow clearance for 1/64 inch end

mill on Modela).

After a couple of iterations and trace adjustments, the DRC came

back with zero errors.

As a check, DRC was run again at 25 mils to ensure it was

operating properly (and provided errors as expected).

Tools/DRC/Clearance tab

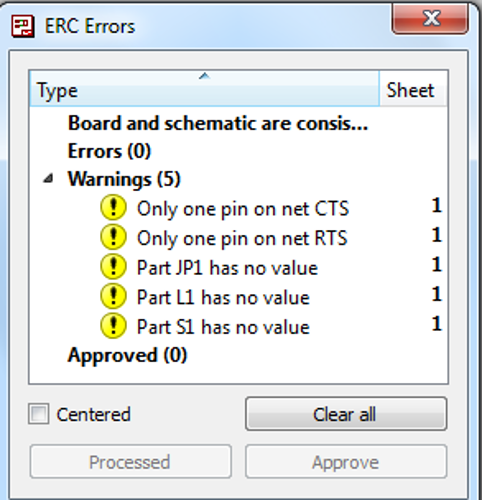

ERC was run and came back with the errors shown

below.

After review, none of these errors were considered significant.

ERC Results

Fabrication Notes

The board was fabricated using the Modela milling

machine.

Traces were cut with a 1/64 inch diameter bit.

The traces.png file was loaded then the x and y start positions

were determined visually based on the material position.

Important Note: You must take note of x,y position now - you

will need it later for board outline cut.

The tool was zeroed in the Z axis by jogging close to the surface

then loosening the bit, dropping to surface and tightening.

The next steps were Make Path, Make rml and Send It which starts

the cutting process.

The outline was cut using a 1/32 inch diameter bit and the same

sequence above.

The x,y start position used for cutting the outline is

the same as that used for the traces.

Assembly Notes

Order of components - Push button, ATTiny,

Resonator, Discrete components, Headers.

In hindsight it may have been better to solder the headers before

the discretes.

Tape the board to the workbench using double sided tape.

The resonator has wrap around contacts (not leads) and is

difficult to solder. Ensure solder is applied on both sides of

leads.

For the 6 pin header, the material available was a straight

through header.

We bent the shorter side of the leads at an approx 30 degree angle

and soldered them to the board.

The connector housing serves as a stabilizer during soldering and

also as an insulator to avoid shorts.

The Outcome

The board did not work on first attempt and we were not able to

download the program.

For debug, we checked continuity on a number of pins around the

microcontroller - no issues found.

At that point the resonator was checked, and the

soldering/alignment did appear suspect.

Removal and resoldering of the resonator did resolve the problem

and we were able to download the program.

However, the LED did not blink when we ran the Arduino "Blink"

program.

It was discovered that the LED component was reversed - rotating

the device resolved the issue.

After these rounds of troubleshooting and repairs the board

worked as designed.