This week's summary

This week's exercise was to "Make Something Big" using the

Shopbot or equivalent computer controlled machining. My project is

inspired by the mess in my home office which bothers me every week

during Neil's lecture. The goal is to make a storage cabinet for

printers and other equipment in my office.

Tools and References

Inkscape was the primary tool used for the design.

VCarve Pro Trial Edition 7.0 was downloaded (free) and was used to

simulate the design. Files cannot be migrated from the trial

edition to the version at the Shopbot machine, but the simulation

capability was invaluable in debugging the design.

Design Notes

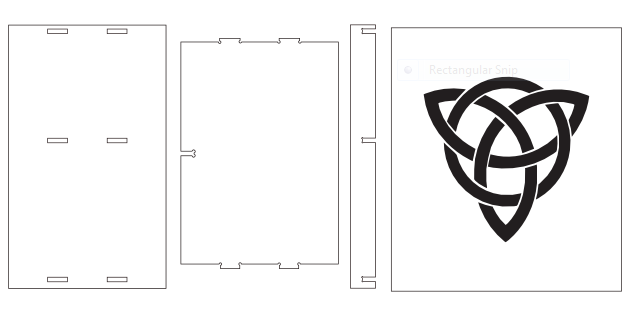

The design consists of 2 sides, 3 shelves, a

support bar and a front door.

Dimensions are approx 40 inches high by 35 inches wide by 24

inches deep.

Design is press fit. Front door has pocket design with Celtic

image.

The image was downloaded as a bitmap file from the web and

converted in Inkscape using the Trace Bitmap command

Side, shelf, support, door (left to right)

Design Simulation

VCarve Pro Trial Edition 7.0 is an excellent tool

to simulate the design.

Several iterations were required to get a good bitmap image. It

is important to get a source file with the image. Much time was

wasted with poor quality images.

VCarve Pro provides an excellent view of the simulated cut.

View of VCarve Pro Simulation

Fabrication Notes

The board was fabricated using the Shopbot milling

machine.

The material was 8 feet x 4feet x 0.75 inch Maple plywood.

The material was clamped in 3 positions around the edge and also

screwed down in 3 positions.

Care must be taken to ensure the cutting profile does not overlap

with the screws or clamps.

X, Y and Z origins must be set to zero.

The pocket was cut at 0.2 inches deep. The profile was cut at the

material measured thickness plus 0.05 inches to ensure cutting all

the way through.

Excellent tutorials are available at http://shopbottools.com/

Shopbot in action

The Outcome

The job ran well (appropriately on Saint Patrick's Day) and the

outcome was very good. Some sanding was required but it worked

nicely. The entire cabinet was sealed and the front door recessed

design was painted. A handle and hinges were added.

Finished cabinet installed

Learnings

A piece of furniture is a lot of work, even for a

relatively simple design.

Last minute modifications of Inkscape line widths can impact

overall dimensions.

Door design: if you do not leave clearance to floor then feet will

be required. Also, large doors are heavy, 2 smaller doors may have

been a better design.

Hinge design: should be considered up front, not as an

afterthought. Many hinges require cutouts. If you do not plan for

these then hinge selection is limited.

Press fit design at this level works well, but lead-ins and

chamfers are critical.