This Weeks Assignment

Design a mold and use composite materials to build a

part.

Part 1: Flower Pots

The idea here was to use flower pots as a 2 part

mold and make a part using my son Shane's old cotton T-Shirt. This

is an example of compaction using a closed mold.

Steps:

Prepare work area with bench covered in multiple

layers of clingfilm to protect against spillages.

Apply clingfilm to outside of inner pot.

Cut cotton material, 4 pieces, slitted to provide overlap.

Gloves, mask, safety glasses.

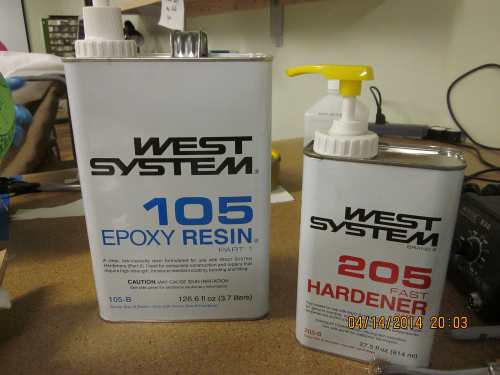

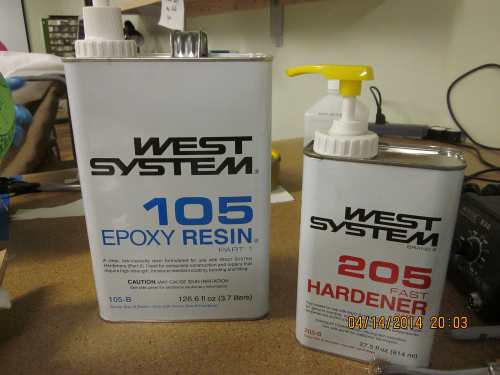

Mix epoxy resin and hardener, equal number of pumps from each can,

mix for 1 minute.

Cover cotton pieces with epoxy mix using squeegee. Target complete

coverage but avoid excess.

Epoxy resin and hardener

Apply each layer of cotton over inner pot.

Apply one layer of clingfilm then perforate layer to allow

bleeding.

Apply bleeder or batting.

Apply mold release to inside of outer pot.

Mount outer pot and clamp in position - leave overnight.

Clamped assembly

The outcome was reasonable but requires some

finishing. The structural properties were excellent. For final

finishing, the intent is to load the part on a lathe. The molds

had to be broken to release the part.

Part 2: Bowl

The idea here was to use a bowl as a mold and

make a part using cotton. This is an example of using an open

mold. The same process had been used previously to make a nice

bowl using a nylon material.

The steps followed were similar to those above. A faster acting

epoxy was used in the wet layup. A heating fan was used to speed

up the drying process. The outcome was reasonable but not great.

The structural strength was excellent but the finish had a

significant number of gaps on the outside. The cotton did not

adhere to the bowl as nicely as the nylon had done. In

hindsight, vacuum bagging would have been a good idea on this

attempt.

Bowl mold and part

Learnings

Working with composites appears to be some science

with a little art. It was a great learning process and future

attempts will be better. The flower pot finish was good where the

mold was fully closed but obviously the finish was less good where

the mold was open.