This week's summary

This week's exercise was to:

- Design and 3D print something that could not reasonably be built

subtractively

- Scan something (print it for extra credit, and make a scanner

for lots of extra credit).

Design and Tool Notes

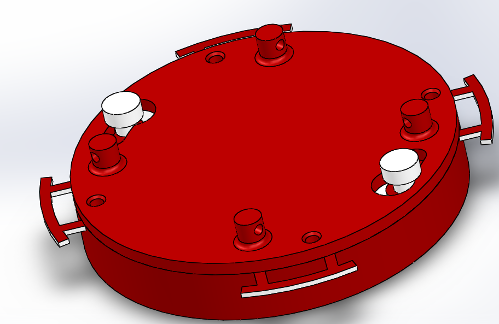

Work has been going on in parallel on the

hummingbird feeder design.

Progress has been made on the use of Solidworks.

While the design is not completed, I decided to print a scaled

down version of the latest.

The Solidworks designs (2 parts, top and bottom) were saved as STL

files.

Makerware software was downloaded to my PC (this is the software

that interfaces with the Makerbot printers).

The STL files were opened in Makerware (using the "Add" button to

include the second part).

Parts were rotated, scaled (down 5:1 approx) and moved to the

platform.

Solidworks Assembly Drawing showing feeder base and

cover

Process Notes

The STL file was saved to the machine's SD Memory

card as a THING file.

The Makerbot 2 machine

was used.

The material was ABS and a

raft was selected (to support the part).

Standard Resolution was used (versus low/faster or high/slower).

The Extruder and Platform heated to 230C and 110C respectively and

the process ran smoothly.

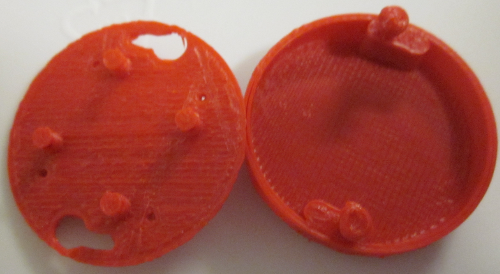

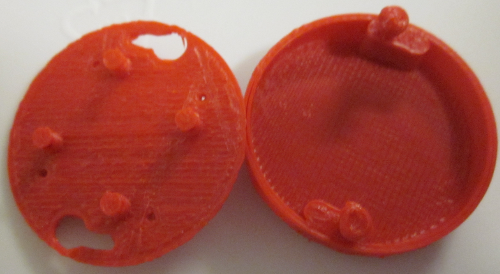

Results: Scale model

The 2 parts printed nicely and actually fit together even at

the small scale used.

All of the features were present and correct, even the small holes

on the top cover boss.

The key design for assembling top and bottom looks like it will

work well.

The process was a good example of rapid prototyping, and some

changes were made to the design based on this result.

Makerbot print output at 1:5 scale (before

addition of perches)

Results: Full Size Model Attempt #1

With access to a machine on campus for the weekend,

and my updated design, we sent the base for printing full scale on

Friday evening. This is what we discovered on Monday morning. We

believe the support material clogged and the part material had no

place to bind, so spun out of control.

Results of failed print of full size

base (B&W photo to reduce file size)

Results: Full Size Model Attempt #2

We sent the job again and it ran perfectly second

time. Note: thank you to my colleague Lee Duerden for SolidWorks

and 3D printing support. The top cover is printing as this goes to

press.

Feeder based printed full size (with support

material shown)

3D Scanning

The first attempt at 3D printing was a good

learning experience but the outcome was poor. I took approx. 35

photos of a piece of fruit and uploaded to 123D Catch. Half of

the photos were flagged as requiring stitching (see photo)

probably due to lighting, but it was extremely difficult to

match the points between photos (123D Catch requests that you

match 4 points across 3 pictures).

I exported the file to Meshmixer. This process

would not work within the application, so I switched to the

website on the Cloud (using my previously generated account

info). A further problem was that this would not work in

Explorer so I switched to Firefox. The file was exported as a

STL file to my hard drive.

I finally got the mesh imported into Meshmixer

for editing and played around with some of the editing

functionality. However, the quality of the incoming image was

poor so the result was poor.

Other Ideas and Reference

Since I will need to test my project before actual

hummingbirds show up in Massachusetts, I downloaded a 3D image of

a hummingbird and printed it on a 2X machine using ABS.

Challenges

None at this time. The 3D Scanning process was difficult and

the practical value of the process with it's current capability is

not apparent to me.