[02/17/2014]

Week 3:

Computer Cutting

This week we were asked to

think of a press-fit construction kit that can generate a

variety of shapes!

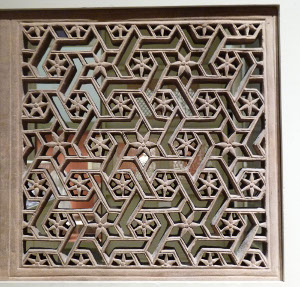

I thought of doing something

related to our culture. I was always fascinated by the islamic patterns

found in walls, floors or doors in the old Islamic Cairo and the arab

countries. So I thought of building a kit that could generate any of

those beautiful geometric patterns that could be used in wall covering

or building furniture.

After some research on the

internet to know more about how such design were thought of I

found this really interesting book Islamic

Art and Design that concluded that any Islamic pattern uses

either a triangular grid or a diagonal grid. The Triangular grid

generates the hexagon star and the diagonal grid generates the octagon

start. So I decided to design 2 shapes 1 will represent the dot or the

joint of the triangular grid with six opening and the other

will represent the dot or the joint in the diagonal grid with

8 openings. I will then cut rectangular shapes that when fixed in the

openings of the 2 shapes will generate any Islamic pattern you could

think of!

My First Attempts

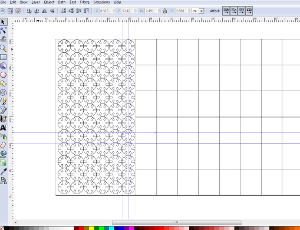

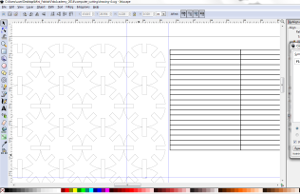

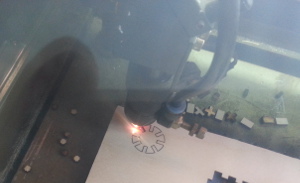

The material that I used was

Plywood with thickness 3mm. I started with drawing the hexagon joint

with a diameter of 2cm and a rectangular piece on Inkscape to

test the parameters that will cut in the Plywood 3mm and the kerf of

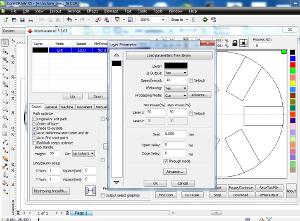

this material with the Lasercutter found in the lab. In order to send

the job

to our Lasercutter I used CorelDraw and the lasercutter plug-in.

First Attempt

First Attempt

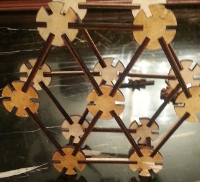

I Found that the kerf is

0.01mm so I used that to

fix the press fit openings in the joint since my original design was

with 3mm openings so I made it 0.29. Also I found out that the diameter

of 2cm is too small to accomodate the 6 openings since when I tried to

fit some rectangular pieces in the joint it was too weak and could

break one of the tooth so Idecided to make the diameter of the joint to

be 2.5cm.

|