Steps:

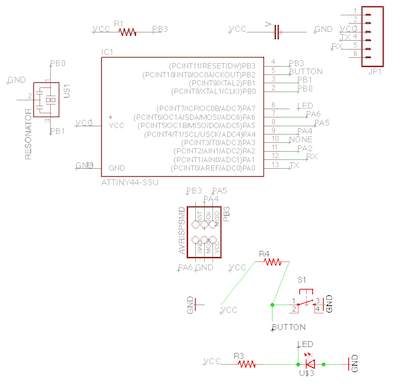

1- Load the schematic file on eagle

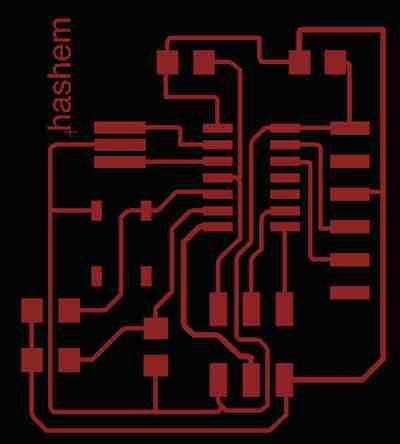

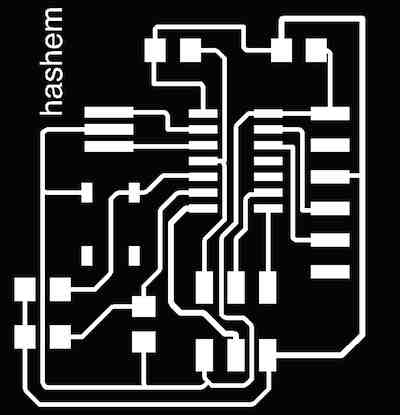

2- Draw the board

3- Invert to black and white on Photoshop. If some lines are not very clear you can edit it using the paint brush.

4- Create an outline which will be the interior (5mm thick).

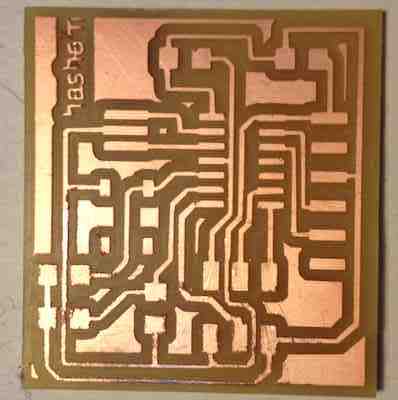

5- Navigate to the modela machine and Fab Modules. Install the (1/64) shank.

6- Load the Traces and Interior files on Fab Modules and follow these steps:

- Use double sided tape to stick the copper board to the work plate on the Roland Modela

- Load .png

- Choose Roland Modela milling machine

- Install the (1/64 diameter) shank

- Load the traces png image of the board

- Change the mill size to (traces 1/64)

- Click on make .path

- Click on make .rml

- Choose your coordinates

- Send the file for milling

- When the machine is done milling the traces, do not move the board!

- Click the "View" button on the switch panel of the Modela.

- Change the shank to (1/32 diameter)

- Load the interior png image

- Change the mill size setting to (interior 1/32) on Fab Modules

- make .path

- make .rml

- Send the file for milling.

- When the machine is done milling, remove the board with care using a sharp tool.

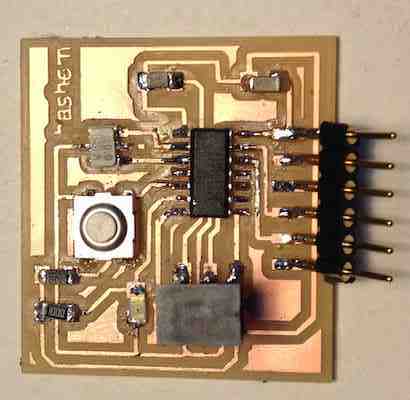

7- Solder the components on the board

What I've Learned:

- To guarandee cleaner traces, modify the line size (wires) on eagle. You can make the lines larger which are easier to mill.

- Make sure to set the image resolution for both the traces and the interior to 500.

- Check the fab modules settings before milling. Some computers have different settings for the same machine/task.

Do not move the board after milling the traces, this will make you lose your coordinates and you will never be able to find the exact position of the board.

- Use Alcohol to clean the board in case it got dirty. Be gentle when cleaning, to avoid displacement of copper traces.

- Use solder wick to remove excess solder, removing solder tips can be found "here" .Click here to download Board File

Click here to download Schematic