This week, I'm making a press-fit modular rocking chair!

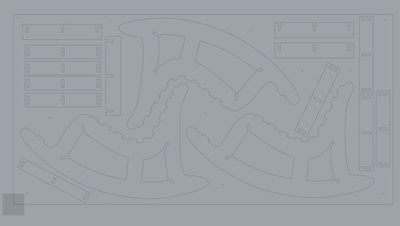

1) I designed the model on Rhino 3D. Make sure you draw the circles (mill diameter= 6mm). Fit into the board 1.5m X 2m.

2) Exported the design in DXF. make sure the 2D board with the parts are on the "0" coordinate.

3) Loaded the file in Partworks. Set the tolerence. Click here for tips on using PartWorks/ ShopBot.

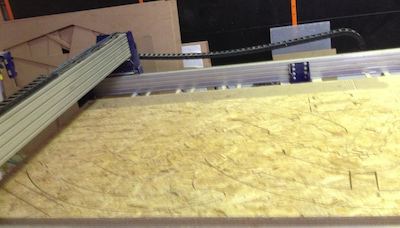

4) Screw different/ empty areas of the board to prohibit movement while milling.

5) Changed the shank on the CNC and set up my x,y,z coordinates (benchmark).

6) Sanded and assembled the parts.

What I've Learned:

- Although I made several tests in attempt to find the measurements for the perfect fit, I still had tolerance issues. Sanding the joints took a long time and serious effort. Always check other students measurements, the dimensions they chose and their mistakes, and try to find the optimal dimensions that for the specific material you're using. Do multiple experiments to test the joints before milling the whole project. This will save material, time and effort.

- Always draw the board you're using for your project (with the correct dimensions) and place all the pieces to be milled inside it to see if they actually fit.

- Position the board you drew, including the parts you want to mill, on the (0,0,0) coordinates on Rhino. which matches the coordinates of the router. In my case, the long side is the X axis and the shot is the Y.

Click here to download the design Files.