Computer Controlled Cutting

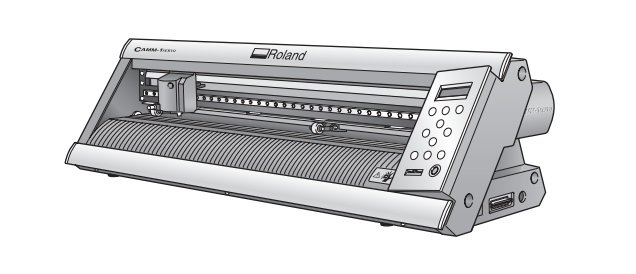

This week’s task was to use cutting machines. For my first work I used the cutter Roland GX24. Roland GX24

This week’s task was to use cutting machines. For my first work I used the cutter Roland GX24. Roland GX24

It is a CNC machine that uses a cutting blade, serves to cut all kinds of materials in the form of iron folded. The blades are in the headstock and can achieve a high level of detail. It is widely used in the manufacture of signals and graphic details. It is easy to use; you only need to choose whether we are going to work with a roll or a piece of vinyl. The parameters that I used are by default, except the speed that was 16 mm/s. For cutting vinyl I used a design of one of my favorite movies (Star Wars), the character that I choosed is Darth Vader. For a good finish it was necessary vectorized image and edit the areas to be lifted to the hour of cutting. As the idea was to create stickers, it was necessary to work with closed curves.

Downloading link for my archives: Archives

For my second work I used the cutter of Rayjet laser Trotec. Trotec Rayjet

It is a CNC machine that has 3 axis, it has a headstock that channels and focuses light to make precise cuts in various materials of different thicknesses. Uses a tube system that generates a laser and it was invented by Kumar Patel at Bell Laboratories. Your work area is 70cm x 40cm. Use was fairly intuitive, then I'll point out the steps:

The character that I chose is an alpaca, which is very representative of my culture and my family, because my grandfather is alpaca breeder since he was 15 years. And its landed property in Puno, is well known for specializing in the breeding of Suri alpacas.

Then, I take two elements very representative of my upbringing. Supported in the idea of starting to future a campaign of revaluation of the andean culture. About the upbringing of alpacas, this activity allows for the survival of at least 190 000 people of the quechua and aymara ethnic groups from various areas of Puno, for this reason, it is important to publicize this kind of work. The prototype has been made using Rhinoceros, in total there were 34 parts. The most difficult part was to choose the tolerance for the assemble, I chose reduce the thickness in 0.25 mm. This thickness worked very well for all the parts with the exception of one that I had to redo because it prevented assemble the head of the alpaca in his body.

Downloading link for my archives: Archives