3D Printing

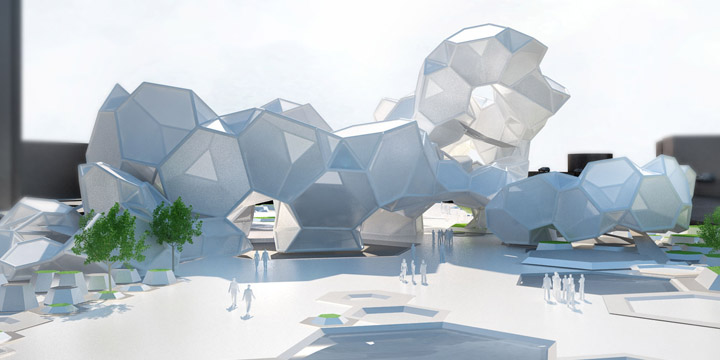

The SOCIAL INNOVATION INCUBATOR (SII) is a project developed during the Self-Sufficient Building Studio of the Master in Advanced Architecture 2012-13 at IAAC by A.Díaz de León R.Garita A.Sollazzo and M.Valenzuela.

The aim of this exercise is to print the 3d model of the "SII" through two 3D printing process:

Process 1: Fused deposition modelling which uses Polylactide filament (PLA - thermoplastic aliphatic polyester).

Process 2: Inked 3D Printing which uses Powder.

Fab Academy Barcelona Class No.6

Assignament: 3D Printing

Process 1: Fused Deposition Modelling (FDM)

Process 2: Inked 3D printing

By Robert Garita

Machines:

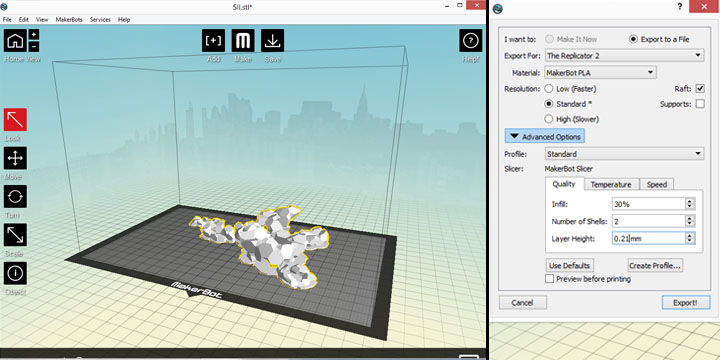

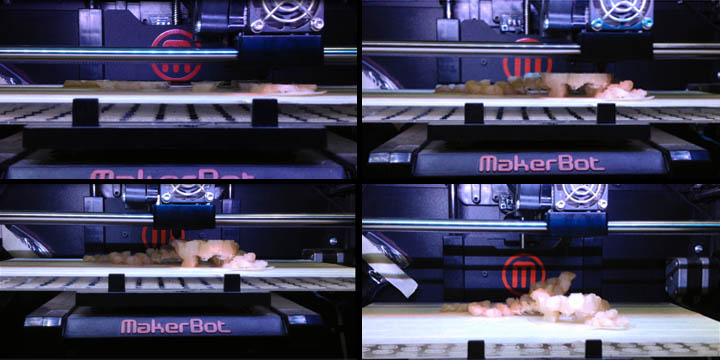

Process 1: MakerBot Replicator 2

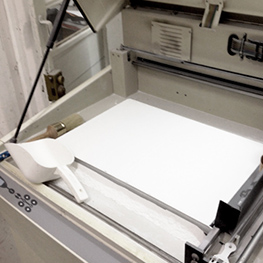

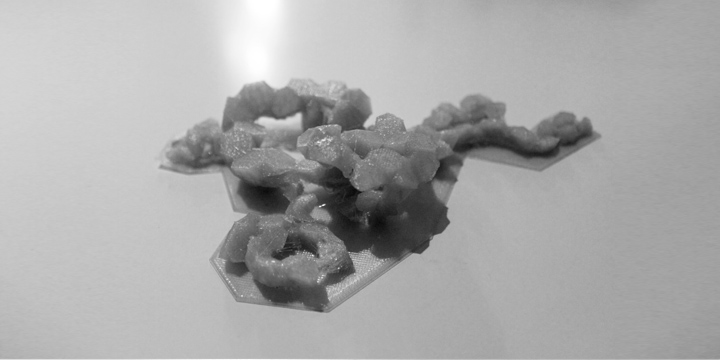

Process 2: Z Corp-Spectrum Z510

Softwares:

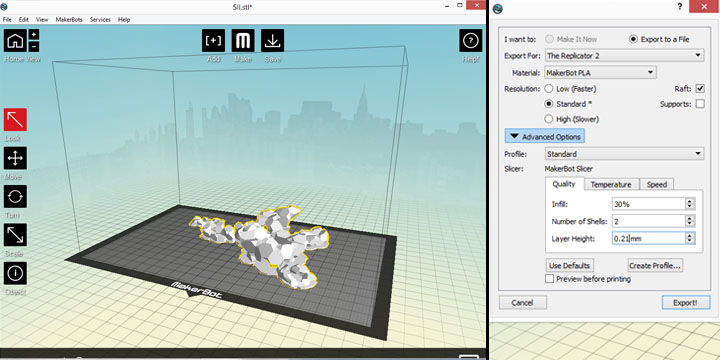

Process 1: MakerWare

Process 2: ZPrint 7.10

Materials:

Process 1: PLA Plastic

Process 2: Powder

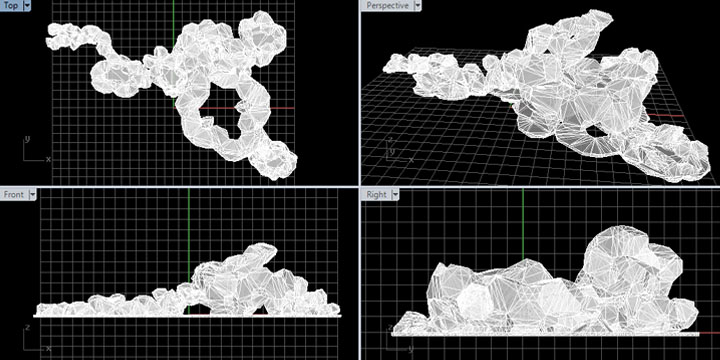

For this process I wanted to evaluate the results of 3D printing, comparing the differents machines we have available: Makerbot and Zcorp, using the same 3D model. The model I used was the one for the final project of the Master in Advanced Architecture 2013.

The first process (makerbot) is based in the Fused Deposition Modelling technique, and the second in the inked 3D printing technique.

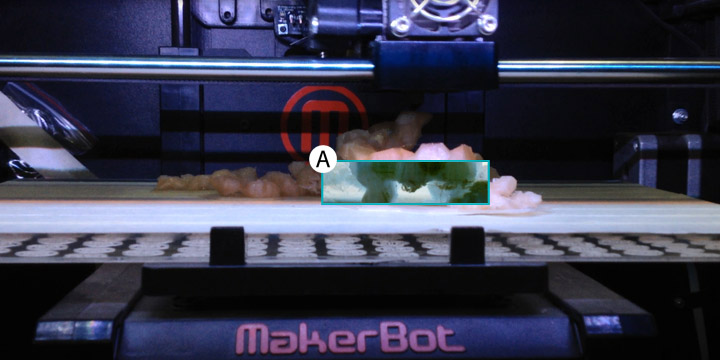

As you can see, the result of the first printing process (figure A) was not very good because the geometry that I try to print has several volumes that have angles that exceed 45 degrees. For the Makerbot it is difficult to add the PLA filament when the angle is too steep because it cannot adhere properly. Gravity matters!

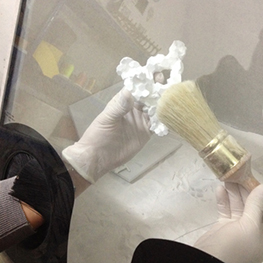

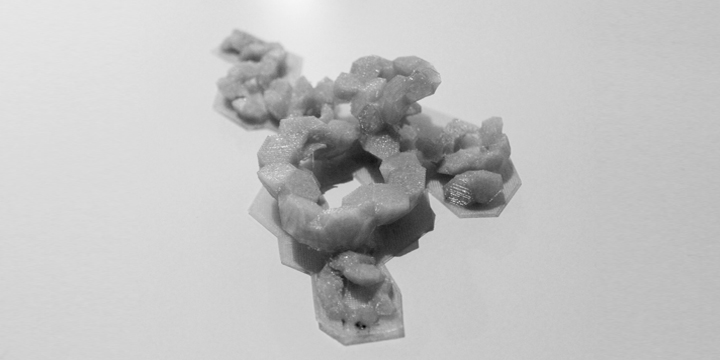

However, the process made by the Zcorp doesn’t present any type of problems in its geometry because the function logic of the machine allows it print any element, no mater if it is on a surface or on the platform of the machine. It is important to consider that the process is way longer and more delicate. The final piece is the result of the injection of resin on powder, which makes them very fragile.

You can download the 3D model from my personal account in Thingiverse