Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog

This weeks task is to make a 'FABISP In circuit programmer'.

We'll be using this device extensivly in later weeks to program our

embedded electronics.

The task doesn't require any creatrive input from us, the designs

are all provided. This week is really all about learnig the

work flow and learning to use the Modela micro milling

machine. However there are a lot of steps to the machining of

the PCB and final manufacture, so there is lots of scope for errors

and it could be quite a time consuming task. For the most part

I followed this excellent tutorial: http://fabacademy.org/archives/content/tutorials/05_Electronics_Production/Assemble_and_Program_FabISP.html

04.1 Workflow

04.1.1 Decide what to actually build!

There are 2 varients of the FABISP, one with a crystal and one with

a resonator to clock the ATTiny44A micro. After a quick check

of the parts available in the Manchester FABLab inventory I decided

to build the crystal based version as the timing for the software

USB implementation would be more accurate.

04.1.2 Use the Modela micro milling machine to mill a PCB

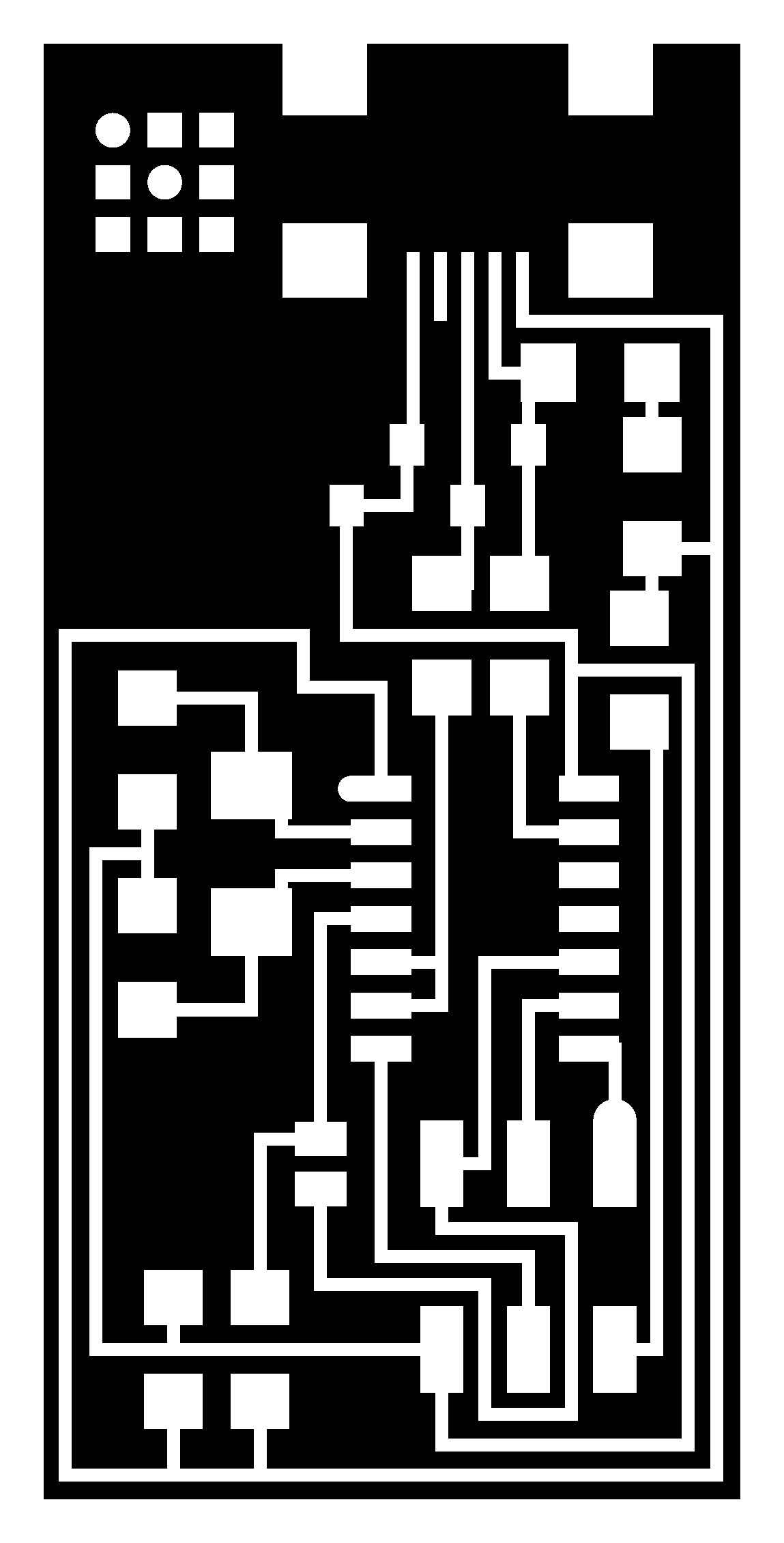

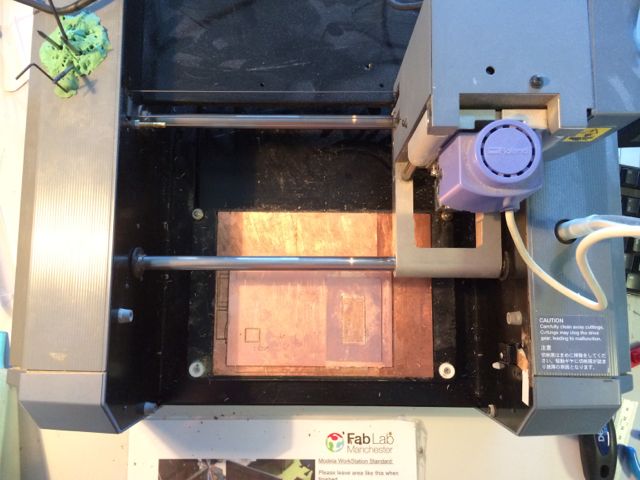

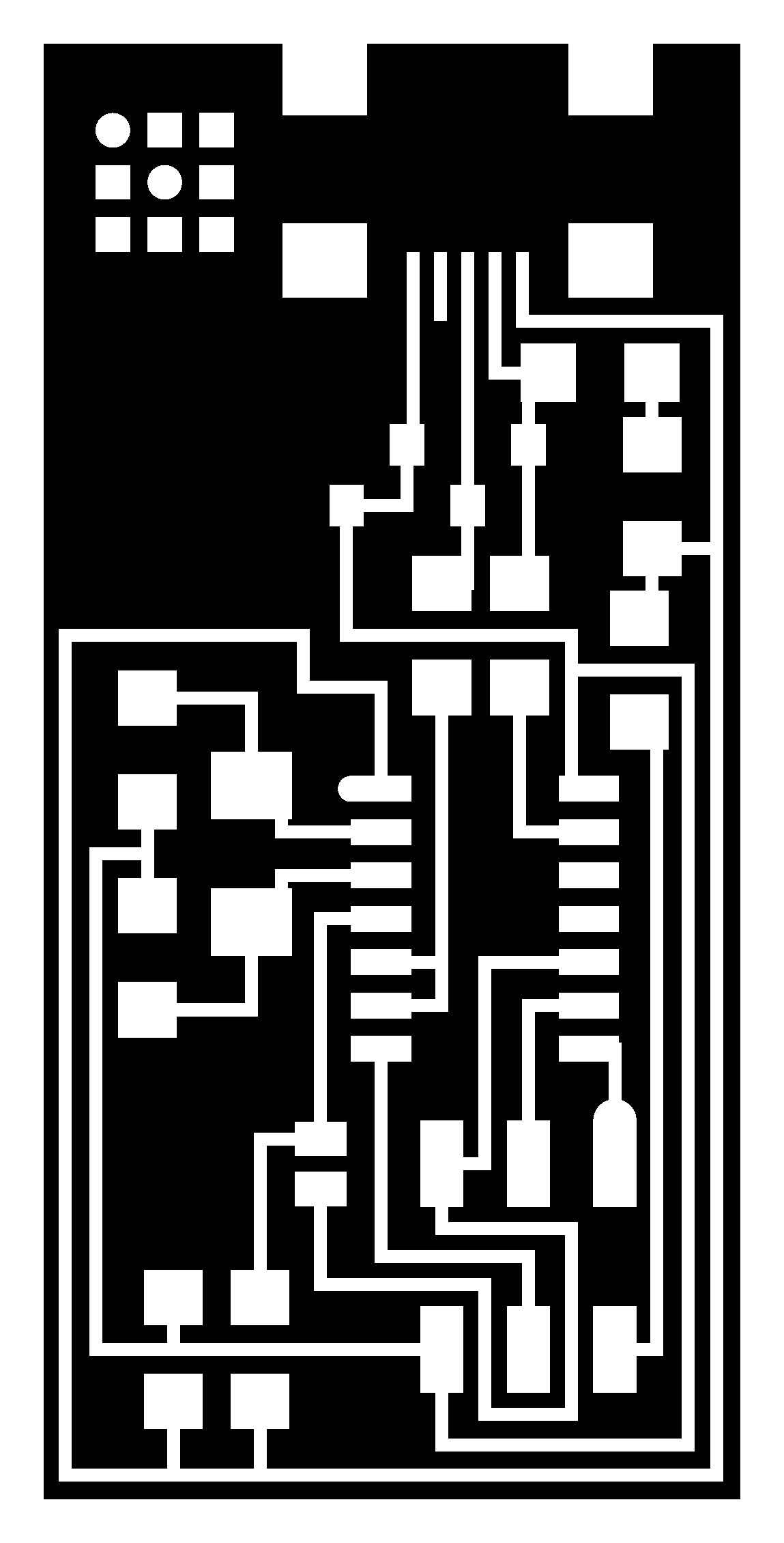

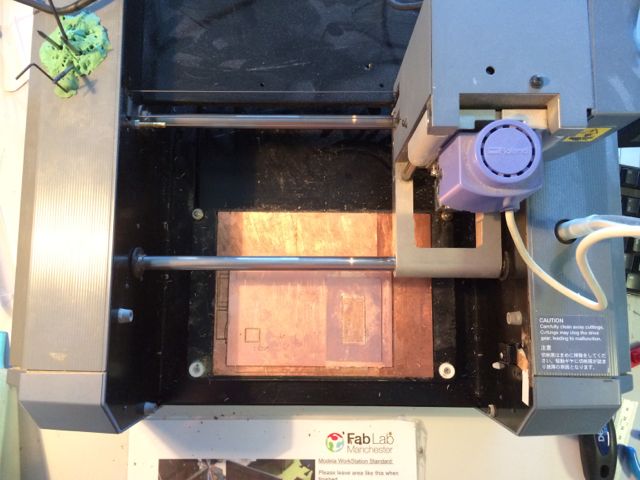

We start with a plain piece of copper clad FR1 PCB and a .png file

showing the pcb traces. Stick the blank PCB down with double

sidded tape, but make sure that there is some sacraficial material

under it, so that when we finally cut the board free we don't mill

into the machine bed and damage it or the cutting bit. It's

also very important to clean the bed before sticking down so that

our PCB material is completely flat. Our PCB traces cut is

very shallow (0.1 mm) so any hight discrepancy of this order will

cause the bit to cut too deep or fail to cut at all in some areas.

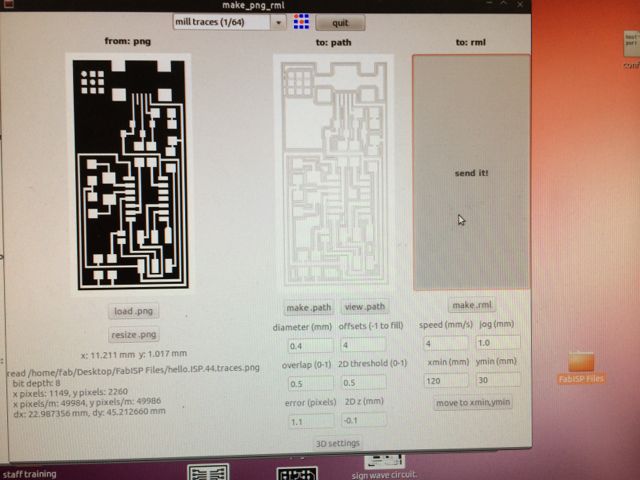

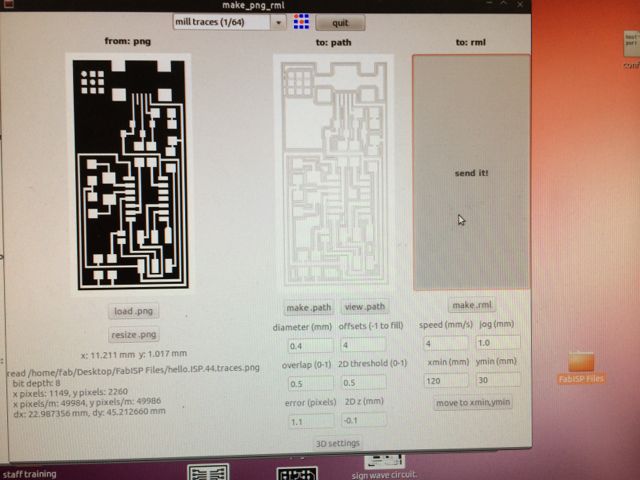

We then select the correct fab module (png to rml) and use the

software to control the machine and mil the PCB as follows

(following the steps from left to right in the fab module):

- Load the .png file.

- Select the type of job 'mill traces (1/64) - this pre-selects

some sensible defaults for cutting PCB traces based on using a

1/64 inch end mill bit.

- Make the PNG into a tool path based on the job type selected

above.

- Set the x,y origin for the area we want to mill so that it's

on our blank PCB stock. This requires a few iterations of

measure and using the 'move to' button to get right.

- We the set the z origin by moving the bed of the machine up

and dropping the bit down in the chuck so that it just touches

the surface of the PCB.

- Finally once the x,y,z origins are set we make an rml file and

send it to the machine

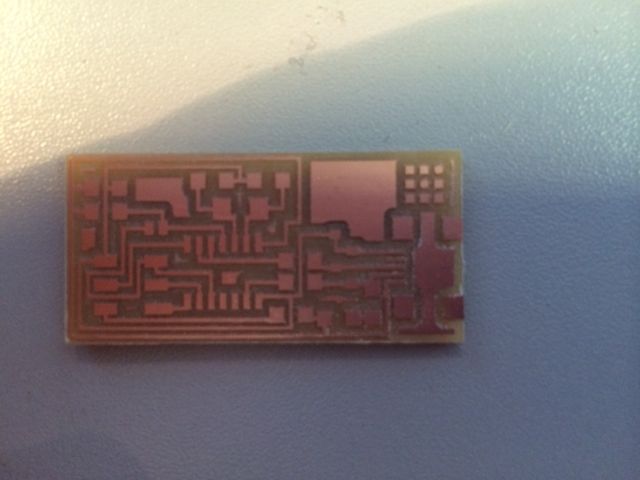

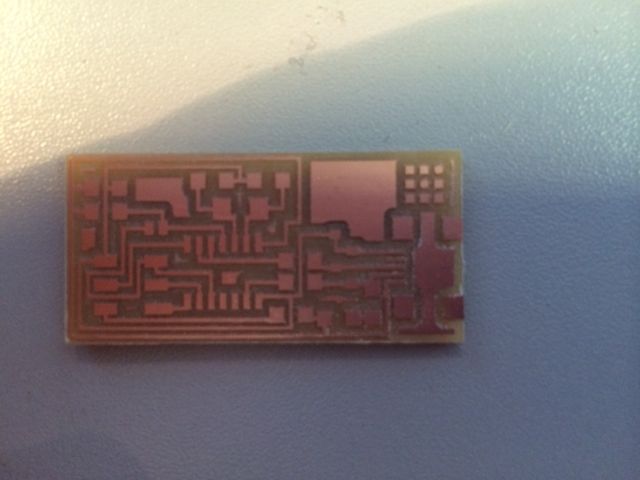

It takes about 10 minutes to mill the traces and you endup with

something that looks like this:

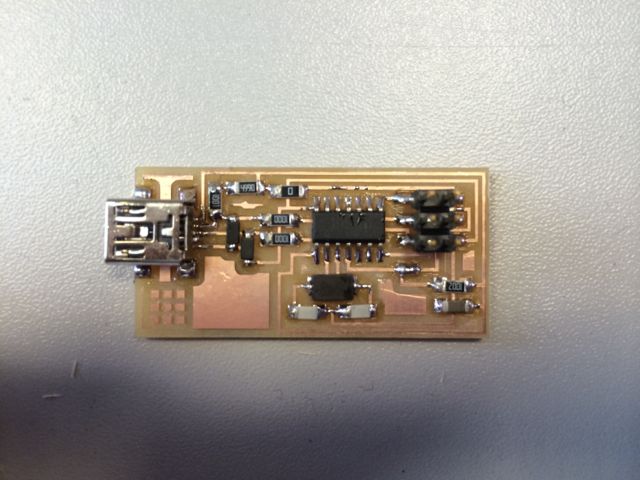

Once the traces have been milled we change the bit in the machine

for a larger 1/32 inch one and repeat the whole process for the

board outline .png to seperate our actual PCB from the stock,

finally ending up with this:

A quick gentle de-bur with a steel ruler and wash with soap and

water to remove and residue and trhen we can populate the board.

04.1.3 Populate the PCB

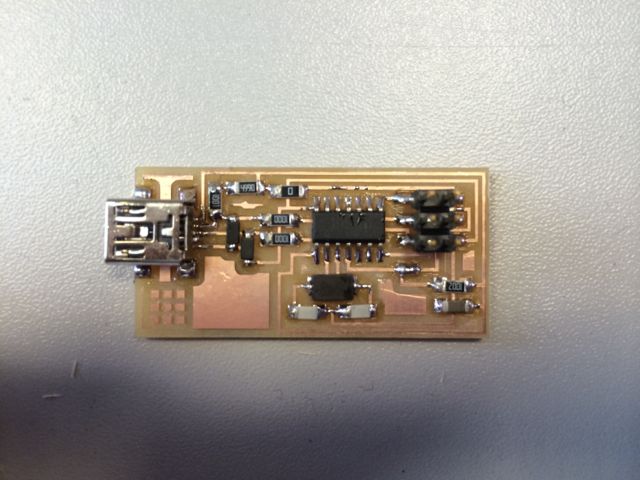

A steady hand and desk magnifier are required! The only

component that I had problems with was the Mini USB connector, the

ones in our inventory have a metal overhang at the back of the

connector that partially shrouds the pins and makes access during

soldering difficult. I'd recommend finding a different

manucaturers connector in future.

04.1.4 Test

- A quick visual inspection under the magnifier convinced me

that I hadn't got any obvious shorts and that it would be safe

to connect to my laptop.

- Then plug into my laptop via USB and check for blue smoke!

- Finally check that I had 5v between the VCC and GND traces on

the board when connected showed that I was at least in with a

hope of continuing.

- It may have been possible to use a scope to check that the

ATTiny OSC was running, but without checking the data sheet I'm

unsure if the initial chip config causes the OSC to run.

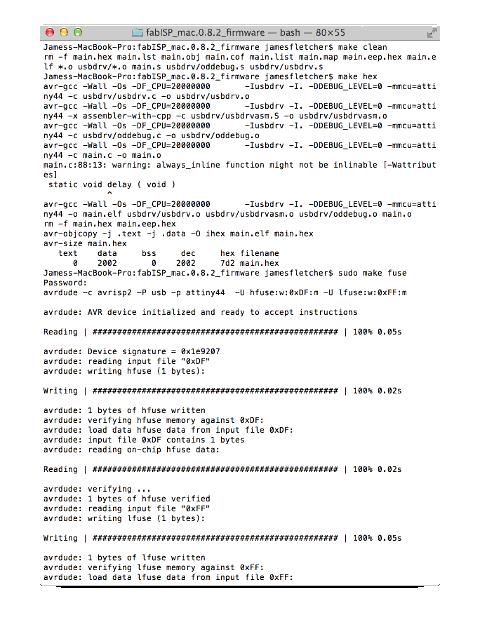

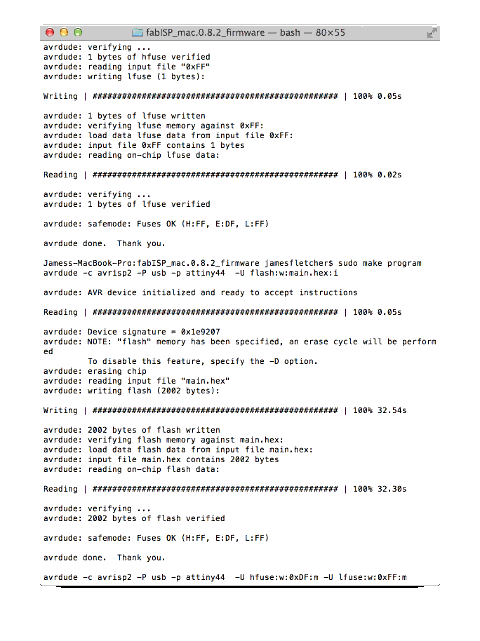

04.1.5 Program the FABISP

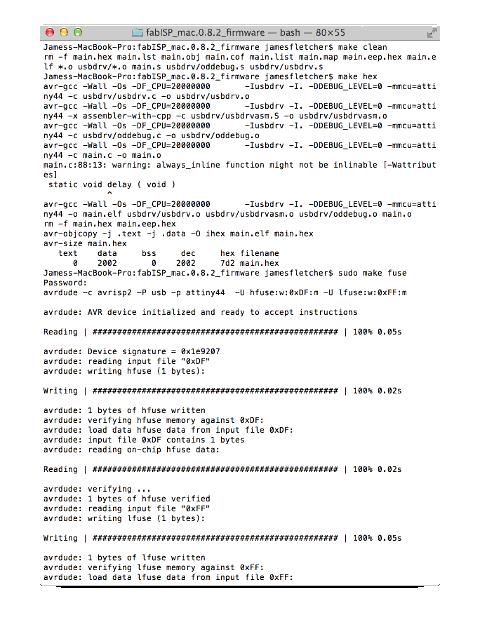

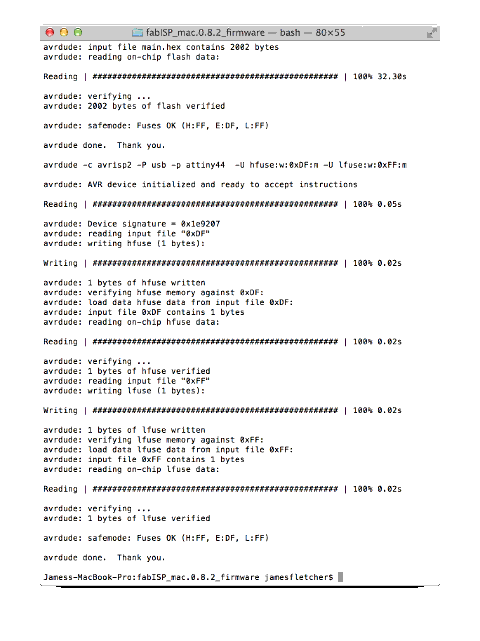

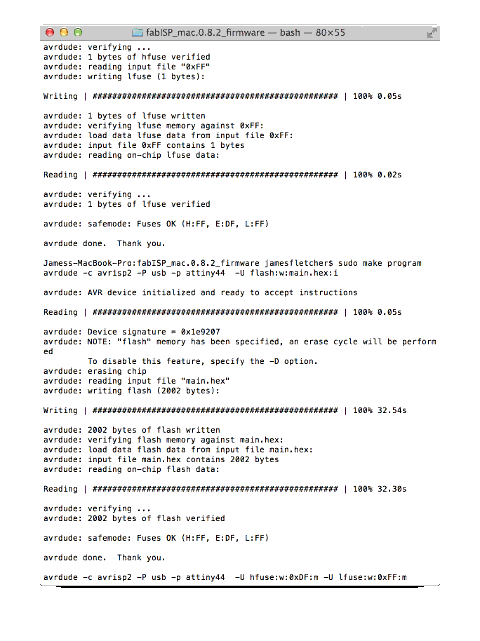

Again following the tutorial, I connected both solder jumpers on the

board (one requires a 0R resistor as it actually bridges a track)

and then used an AVRISPmkII to program. Note I had to connect

the ISP connector the other way around from that shown in Anna's

tutorial that I was following.

Also note that I got a single warning about function in-lining when

I complied the FABISP firware.

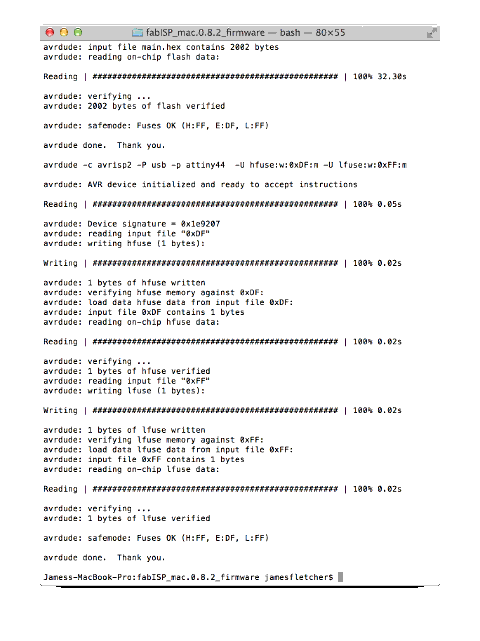

Once I had successfully programmed the device it appeared as

'FABISP' in my Mac system report. I then removed the two

solder jumpers.

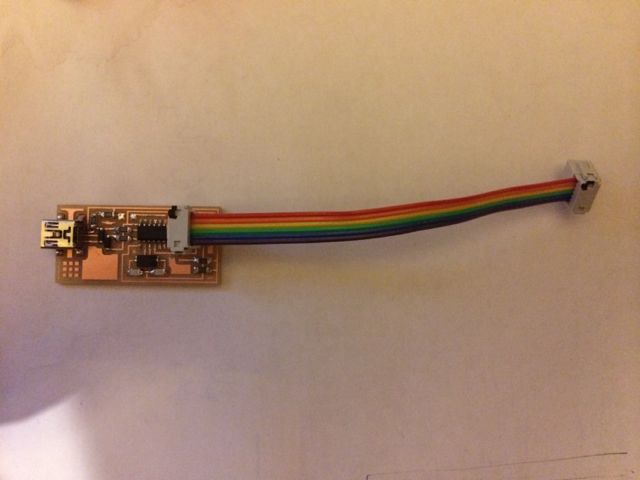

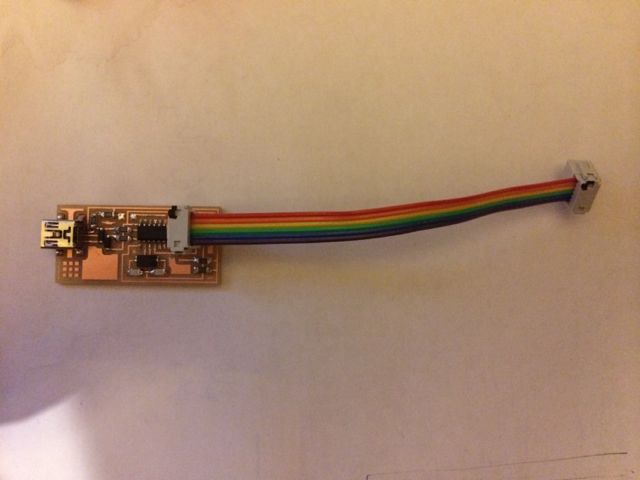

Here's a picture of my finished device with black dots marking pin 1

on the ISP connectors.

04.2 Problems with the Modela

The only issue we had was that at one point the Modela and the PC

driving it got out of sync for one of our students. We had to

delete the 'print jobs' from the controlling PC and then reset the

Modela. To delete the jobs run:

ps -aux

And identify the two processes that need to be killed. One is

called something like 'rml_send' and the other is 'cat fab.......',

they should have consecutive process numbers. Then kill each

process by number with (e.g. process number 2266):

kill -9 2266

Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog