Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog

13. Networking and Communications - Laser Tag!

This weeks assignment was to "design and build a wired &/or

wireless network connecting at least two nodes." I'm intending

to use IR communication for my final project and so I decided to

test this by making a 'Laser Tag' game.

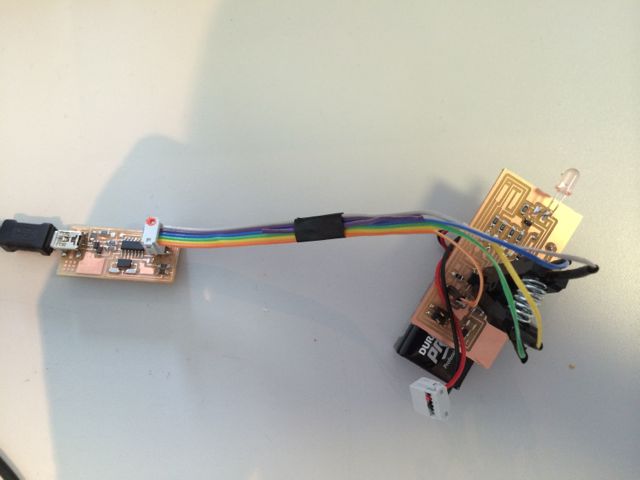

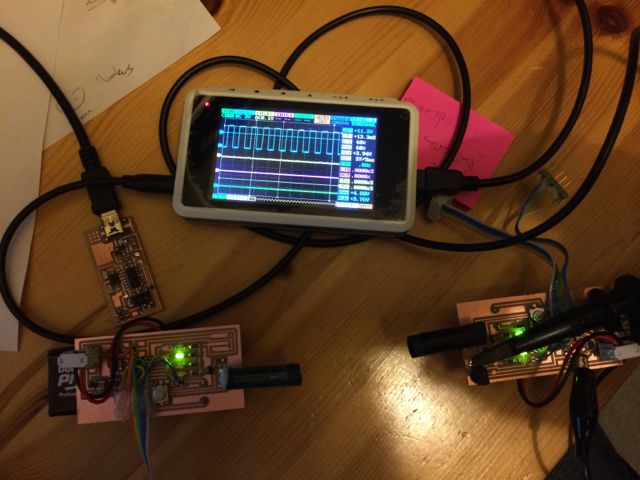

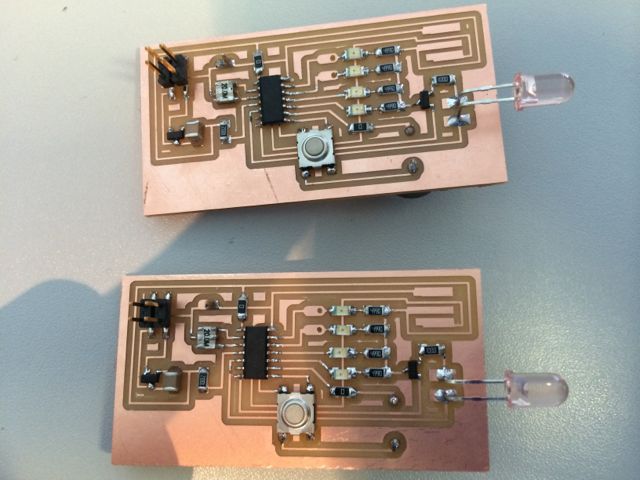

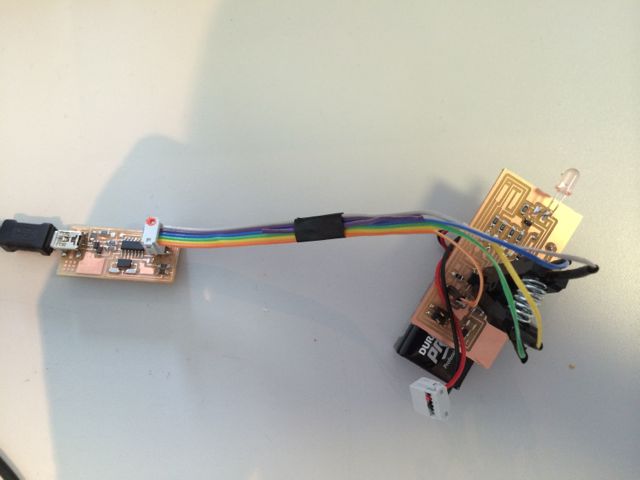

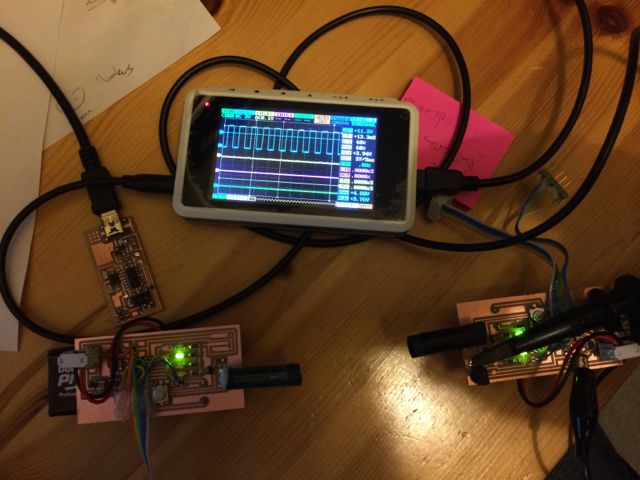

Three Laser Tag Network Nodes, one is also wired with an RS232 port

to use as a bridge node to the PC so that scores and tag statistics

can be reported. Design files are lower down the page.

Me and Mike testing the Laser Tag in the Lab.

Fab Lab Laser Tag from James Fletcher on Vimeo.

13.01 Conclusions

It works, but the range is rubish and the error rate huge!

More time is needed to finish the software to demonstrate all of the

features I intended.

Thoughts on why range is so poor...

- Rubish encoding scheme.

- Bit lengths not matching IR reciever spec.

- IR Rx unit with unknown carrier frequency may not match my

modulation. The parts I actually ordered didn't arrive in

time and I ended up using some unmarked IR receivers scavenged

from a dubious source.

- IR LED 880nm but IR Rx 940nm.

13.02 Design Criteria

Nodes should be addressable. With support for 15 addresses and

one 'broadcast to all' address. Nodes should be able to keep

tally's of which other nodes have shot them. These tallys

should be reported to a PC at the end of the game for overall score

calculation.

It should be possible to start a game, end a game or reset nodes

from the PC.

The physical design would need:

- IR transmit / receive.

- LEDs to show 'health'.

- Buzzer for feedback.

- Switch for trigger.

- Battery power.

- Minimal extra connectors, so decided leave off ISP header and

program with 'clip' direct to ATTiny44A.

After a quick read through the RC-5 spec for IR remote controls

there were a few obvious take aways:

- Signal needs to be modulated with a carrier to distinguish it

from the background noise.

- Bit encoding scheme needs to include at least one transition

per bit (a Return to Zero code or Manchester code) allowing self

clocking and stopping the AGC in the receiver from being

swampped (see test below).

Carrier modulation in the AVR is OK, it's just a squarewave at a set

frequency.

Carrier de-modulation could be more of an issue, it would require

detection of the carrier and gain control of the receiver

stage. Carrier detection could be done as a digital signal

processing task. However gain control is more difficult,

requiring either analog sampling of the signal from an IR photo

diode, modification of the bias on the diode or control of an opamp

stage. I did briefly look into doing these tasks myself in the

AVR, but dedicated receiver chips such as TSOP2238

and IRM-3638T

are so cheap (sub $1) that it seemed rather pointless to waste my

time and AVR CPU time on solving the problem.

13.03 Initial Signal Tests

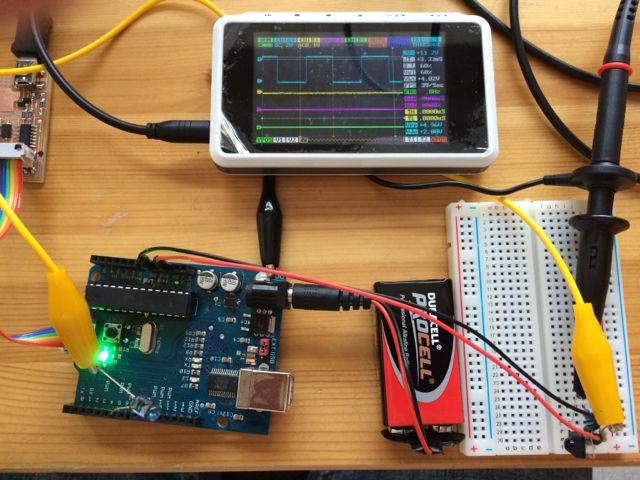

I did some initial signal tests with an unlabled IR receiver chip (I

think it's an IRM3638T) on an Arduino. I looked (not very

scientifically!) at the following:

13.03.1 Ability to Modulate a Basic Squarewave Signal and

Receive it Full Stop.

This was the first issue I had. I was squirting out a 38KHz

carrier modulated with a steady 500Hz 50% square wave via an IR LED

from the fab inventory. However nothing was coming out of the

receiver! I had a small IR remote control designed to work

with the receiver chip I had. The signal from the remote

showed up at the receiver output.

After lots of head scratching I eventually noticed that if I blocked

the beam it worked briefly when I allowed the beam through

again. I turns out that the AGC circuit in the receiver was

saturating, it needs pauses between bursts of data for the ACG to

recover.

Once I did 200ms bursts of modulated carrier and 1000ms pauses

between them the signal came out of the receiver perfectly.

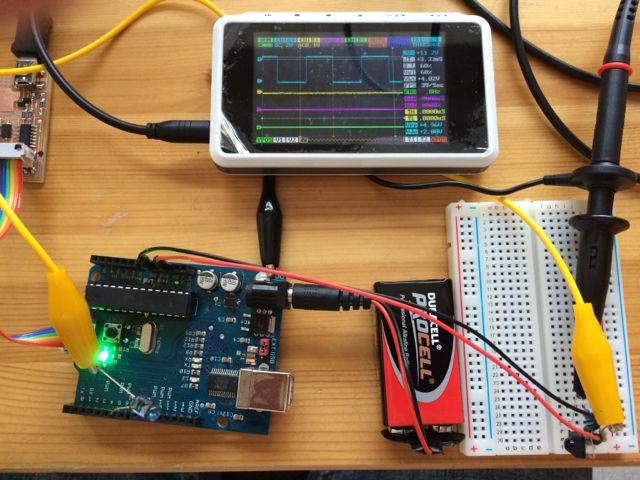

My basic rx test rig:

13.03.2 Transmission Distance.

I seperated the rx and tx sections and carried the rx unit around

the room. I managed to see a signal out of the rx at distances

over 6m. However I was only looking for a squarewave out so

actual signal quality was unknown at this point. To achive

this distance I had to push the IR LED drive current up to around

40mA. The rx unit data sheet suggests ranges of up to

20m are achievable.

13.03.3 Beam Reception Angle of the Receiver.

At distances of around 1m I twisted the receiver with respect to the

transmitter. When they were 90deg out so that the tx beam was

hitting the side of the rx unit I was still getting a squarewave

out.

13.03.4 Effect of Beam Collimation With a Simple Cardboard Tube

Around Transmitter.

Next I tried collimating the tx beam with a simple cardborad tube

and looking at how far 'of axis' I could move the rx unit before

loosing the signal. Initially this didn't seem to have much

effect until I also plugged the back of the tube with BluTac.

Moving the rx unit more than about 20 degrees off axis caused the

signal to be lost.

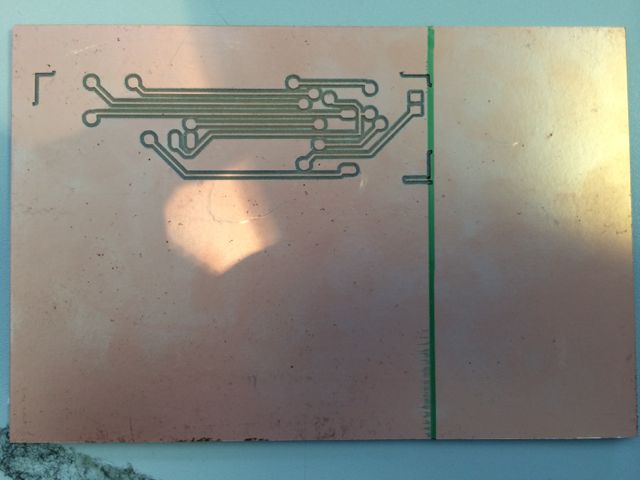

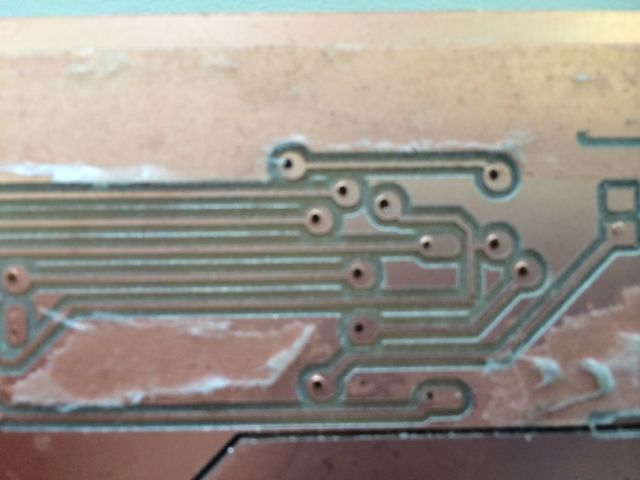

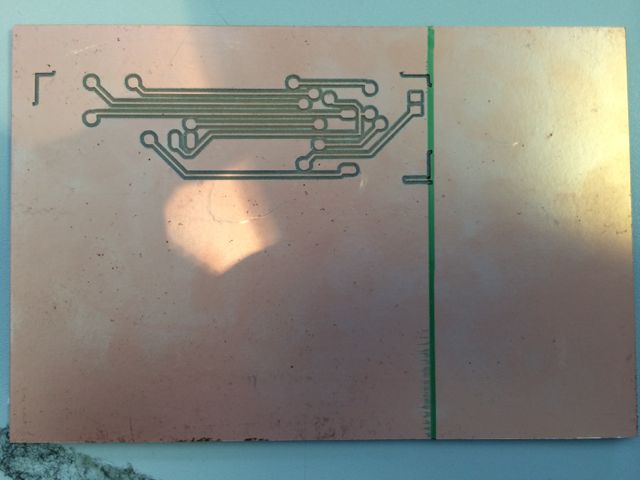

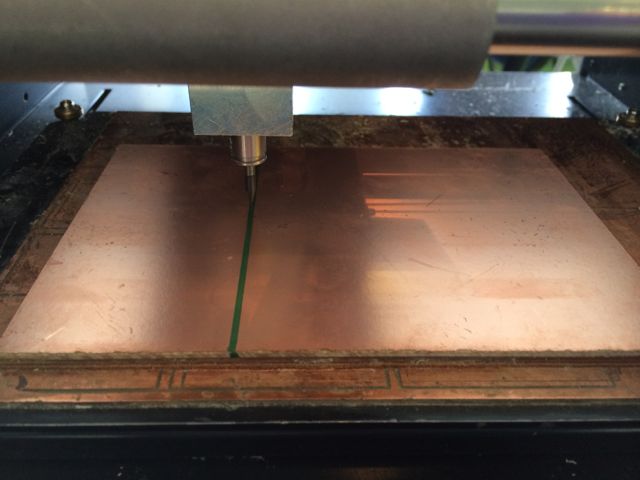

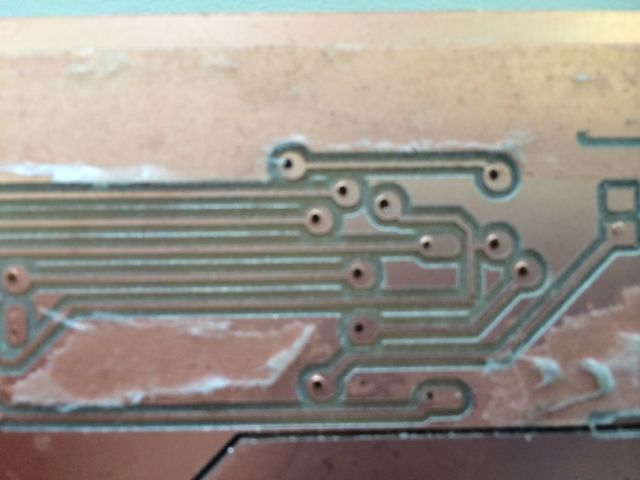

13.04 Inital Design as a Gun Shaped PCB

Initially I tried to mill a double sided gun shaped PCB complete

with 3x AAA batteries in the handle. This required working out

how to get the registration between the top and bottom

surfaces.

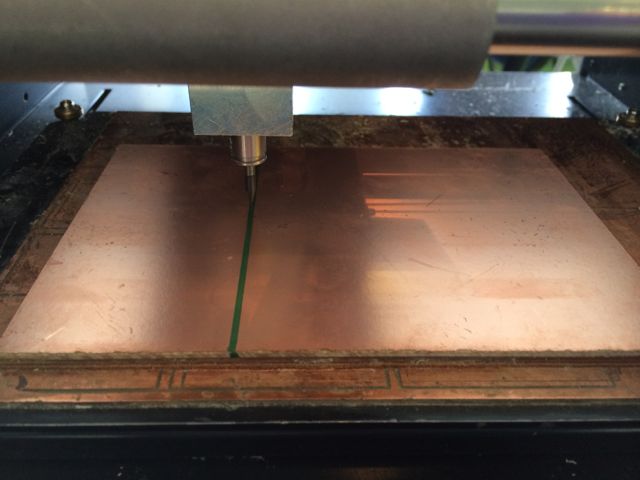

I stuck the stock double sidded copper board down with the lower

edge parralel to the bottom of the bed on the Modela. I milled

the bottom traces first, including some registration marks at the

boundary of the PCB. I then carried these marks to the edge of

the stock board and around to the other side, before flipping the

board left to right and sticking down parallel to the Modela bed

again. I then zero'd the bit on the center of the registration

mark. This way I was only having to deal with registration in

the x direction between the two sides of the board.

The registration between the top and bottom surfaces was OK as can

from the through holes on the via's in the photo below.

However ultimately this PCB design was a failure as the bed of our

Modela doesn't seem to be that flat and I couldn't successfully mill

a PCB that covered most of the bed. To get this one working

PCB I went through 3 of the 1/64inch bits! Need to re-level

the bed before continuing with this experiment. The PCB's also

end up with sticky tape on both sides which can be a mess to clean

up.

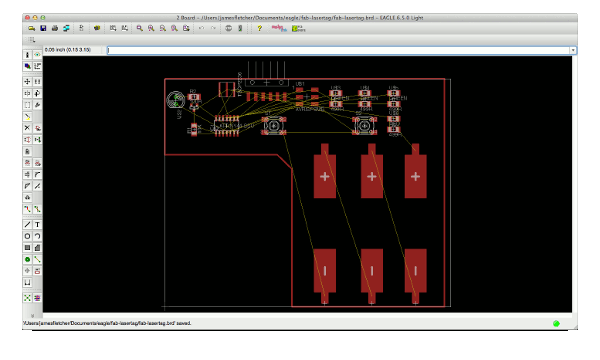

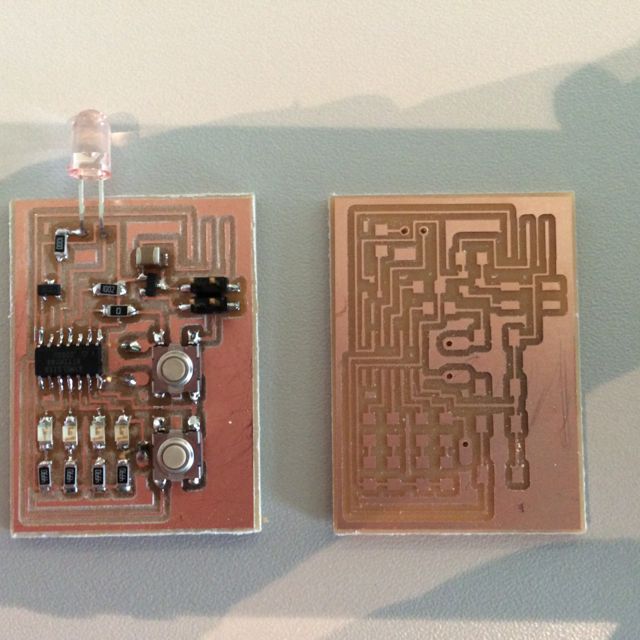

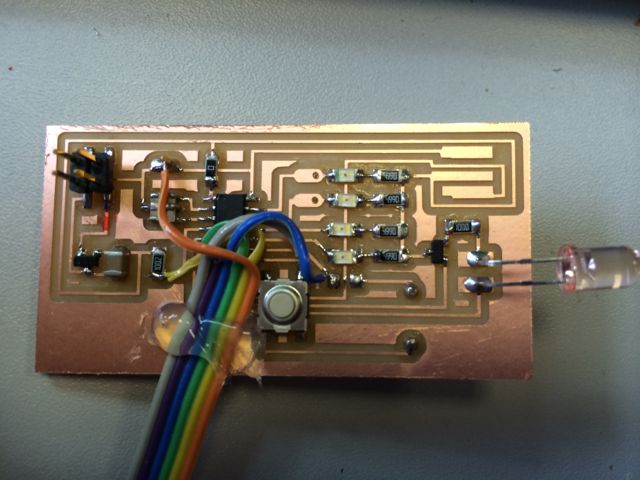

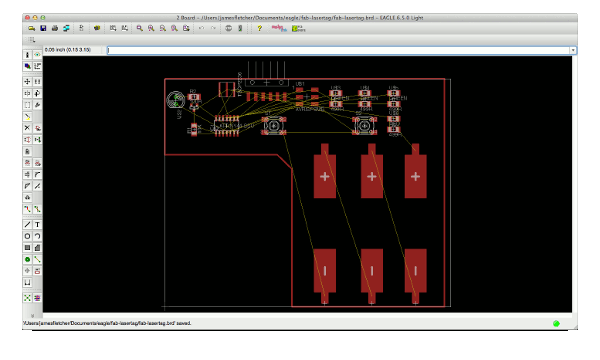

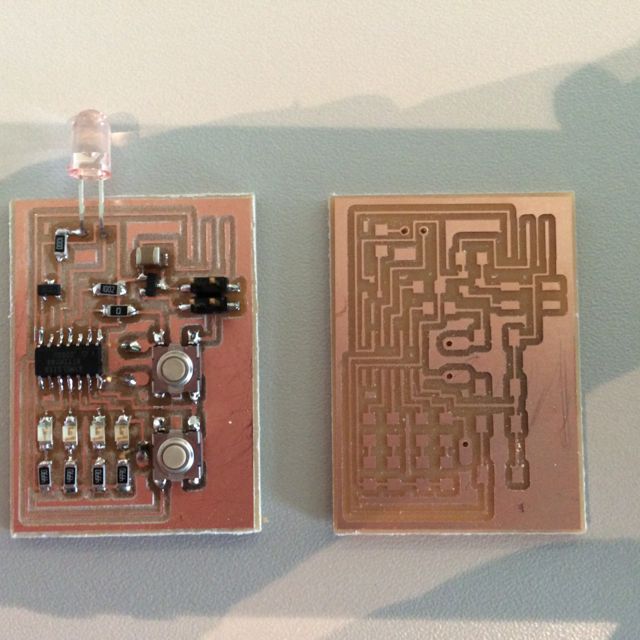

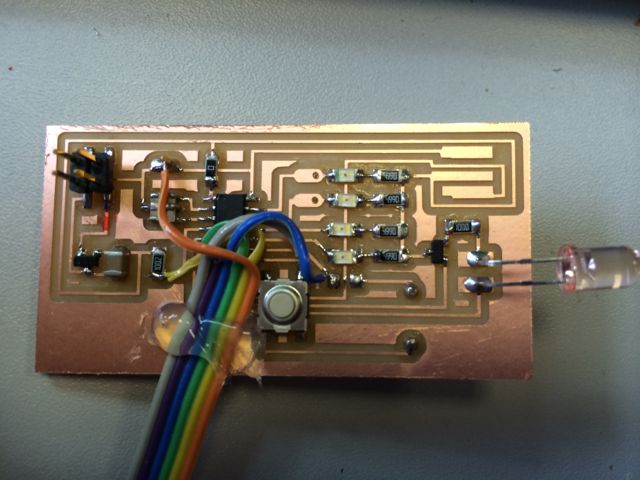

13.05 Second Board Design

I decided to make a much smaller single sided board design, but by

this point I was running out of time and starting to rush so I

forgot to add the resonator! Fail! Decided to get some

sleep and attack it with a clear head the next day.

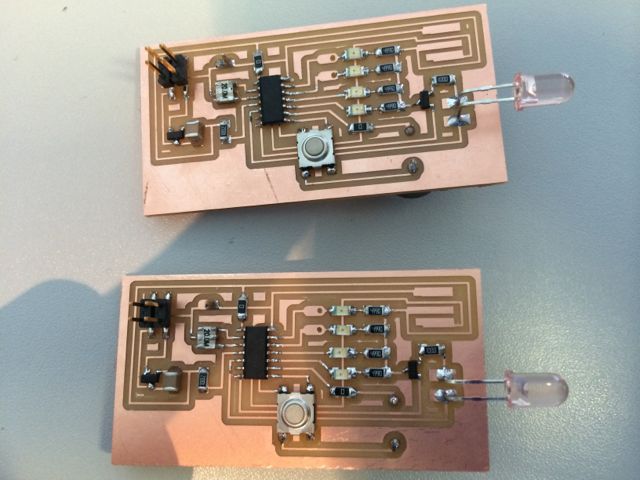

13.06 Third and Final Board Design

Third time lucky. Eagle schematic and board files are here.

Initially I had planned to program the boards with the 8 pin clip

direct to the ATTiny44a. Even though the clip only has 8 pins

and the AVR has 14, the clip will cover all of the required pins

except GND, so I just added a seperate GND test point to the board.

Using this method I just couldn't get reliable connections to the

AVR. I'm not sure if it was because the clip was designed for

an 8pin package, close inspection looks like it should still contact

the required pins OK. I suspect that it's due to the lumpy

soldering on some pins causing the clip to stand off slightly.

As I was pushed for time I just soldered a programming cable

direct to each board. Note that the IR receiver isn't fitted

as I was still waiting for the parts delivery.

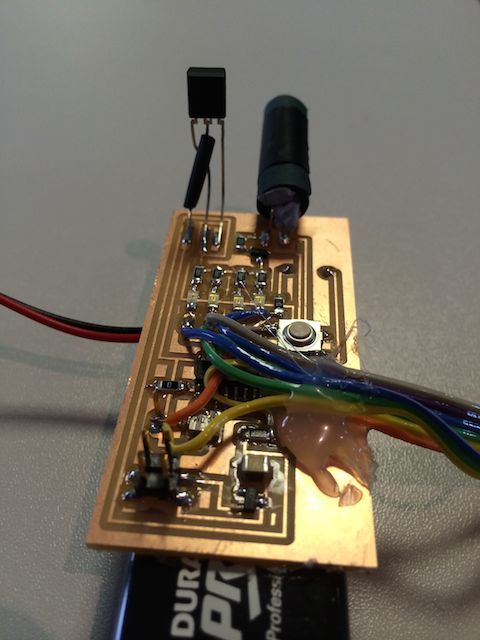

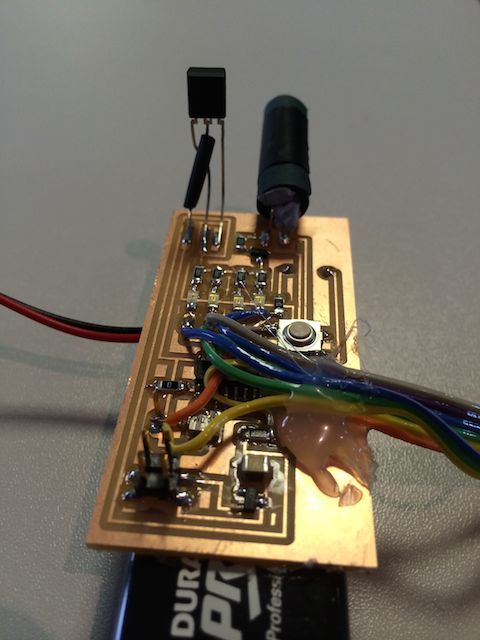

Final board with collimated IR LED and BluTac to plug the hole at

the back of the cardboard tube.

13.07 Software Development

I had really run out of time by this point and soo decided to keep

it really simple. Code is here.

I had planned to implement address allocation via a broadcast

message to the PC, this was dropped.

I had planned to implement media access control by loooking to see

if the channel was busy to avoid collisions, this was dropped.

I had planned to implement multi-byte messages, this ws dropped.

I had planned to implement a PC bridge node, this was dropped.

The units do look for a valid communication, they buzz and decrement

the players health if the player gets shot. They only fire

when the player has health and fire twice per second if the player

holds the trigger.

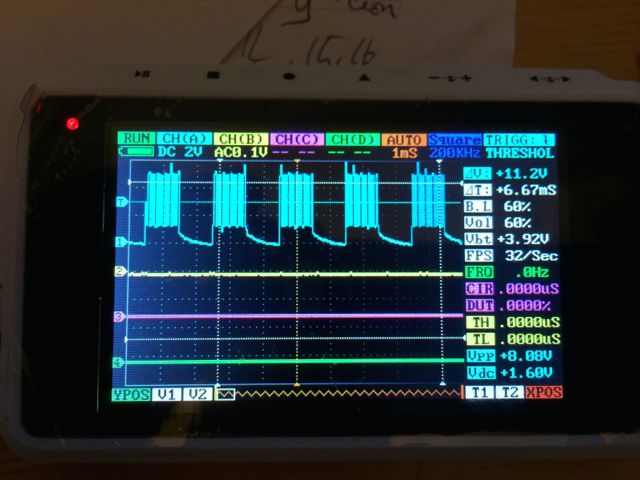

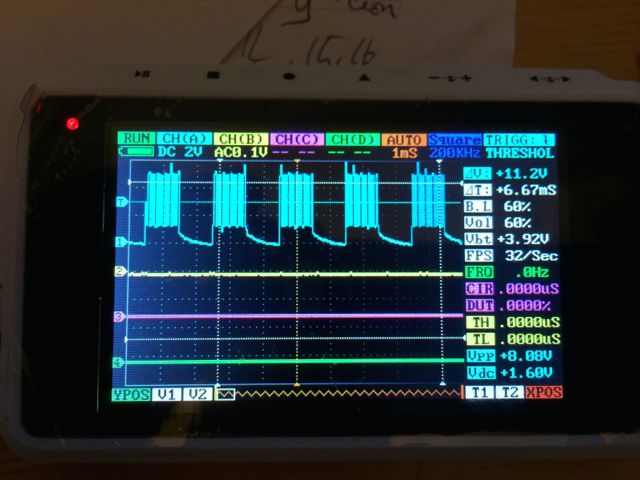

Modulated carrier signal on scope and communications tests:

The major problem I've had at this point is the bit error rate, as

the range increases beyond a couple of meters the error rate rises

dramatically and makes communication impossible.

13.xx Design notes - Bit of a brain dump and not yet formatted

into anything coherent.

I've started using this weekly page to keep notes as I design, so

that I can write up more easily later. Nothing below this

point is formatted, it's just my notes.

IR comms

looked at doing de-modulation myself. Can do demodulation

OK, but AGC would be complex. At that point it just becomes

cheeper and more reliable to buy the off the shelf part

Vinyl Cutter 2 Layer PCB Test

To Add Vinyl cutter as a raw printer on Mac, start cups admin

interface on MAC - localhost:631

Add Roland GX24 as a 'raw' printer with the name 'vinyl'

Works from fab modules

To make Via mask export tStop bStop

Nodes are:

Gun x3

Bridge to PC x1

Required features

Media access - collision detection - collision avoidance (back off

by random amount?)

Message framing - message addressing - message error checking

IR Test

setup timer 0 to generate as close to 38KHz as I could get

16MHz / 8 = 2MHz / 53 = 37.735KHz, then cycle that on / off at 2ms

intervals by disabling OC0A

At first I tought not working, but then I notice some signal after

blocking the beam. Rx ACG seems to block signal if it's on for too

long.

=> must use a RZ coding to stop AGC cutting out signal

Use Manchester coding as per RC5

Rx unit is http://www.everlight.com/datasheets/IRM_3656T.pdf

(38KHz carrier - I had some of these lying around to test)

or TSOP2236 http://www.farnell.com/datasheets/30485.pdf (36KHz

carrier - this is what I ordered for the assignment)

Rx unit Expects > 10 carrier cycles to lock on (260us minimum

pulse)

Claims 6m rx distance at 45deg off axis

Expects 400 - 800us pulse width

expects 25mS between messages (assume for ACG to recover)

Rx unit is quite directional according to datasheet at 80deg it's

10% of the on axis sensativity. Mount tilted a few deg

towards the front of the gun?

What should my bit timing be? if bit timing is 800us per bit (1250

baud) then edges will be either 400us or 800us apart.

A 5 byte (40 bit) message would take 3.2ms to transmit - This is

probably Ok from the point of view of collisions when there are 4

nodes. Also as it's the recommended rate is probably OK from

the point of view of errors.

How will I detect incoming bit stream

Option 1) use sw to time the rate at which edges arrive.

Need to check a timer or count in a delay loop between pin

changes. Would consume all PCU time not allowing fancy

flashing LED's etc.

Option 2) use timer1 input capture to time rate at which edges

arrive. Frees up CPU time but consumes a timer that may be

needed in future swarm bot project. A software IRQ every

400us to possibly change the edge state and provide an app tick

would be acheivable. Input could drive INT0 and check the

current timer value to read data. CPU load would be very

high during tx

Option 3) Alternatively we could use the SPI output to mux the

carrier on/off. Doesn't support NRZ encoding, but may not be

a problem for such short messages.

Option 4) Use the SPI at double the data rate and encode the bits

into a pseudo NRZ pattern. Requires a Timer for baud rate

generation. Not very good at async reception due to lack of

ability to detect start condition well.

Option 5) Move to ATMega and use USART

on 400us irq -

inc tick count by 1, 2 or 3 depending on last bit count timing?

check tx bit count, shift bit out if required by setting up next out

compare timer

message format similar to IP packet

SRC addr, DST addr, Length, target function, seq number (starts at

arndom, allows us to address b'cast packets back to correct

device), payload, csum

Need a b'cast address

Need functions for:

- address alocation

- shoot type 1

- shoot type 2

- shoot type 3

- report kill

- send score to server

- request score

- start game

- end game

Repeat all messages 3 times to aid reception? At what rate?

Do we have 2 Tx per node? collimated and broadcast?

Basic test - see signal (200 repeats of 1ms carrier / 1ms

no-carrier, followed by 1000ms no-carrier)

Range test - uncolimated, falls apart after about 2.5

meters. (680R current limit. Looks like 1.2V across

diode, therefore 5.5mA)

Re-try with 100R, works up to 6m with line of sight

Will require much lower resistor when running on 3v from 2x AAA

Colimation test. Not very scientific measurements. 25mm

long black heavy weigght paper tube (3 layers). 5mm of it behind

LED. Up close it gets the signal all of the time due to

leakage out the back and reflections, but further away, go more

than about 20deg off axis and it looses the signal.

Will rx run on 3v? yes runs on 3v3 form arduino, or 4.5v from 3x

AAA cells

Rx angle test. Up close it gets signal from all angles

AVR Resource allocation:

Timer0 (8bit) - generate carrier

OC0A (PB2) - carrier output

Timer1 (16bit) - time edges in rx signal, generate edges on tx

signal also generate in app ticks? may miss some but should be ok.

ICP1 (PA7) - rx signal in (page 106) or use in PCINT mode

OC1A (PA6) - tx signal? use out comp to modifiy carrier and update

tick count (also MOSI pin)

Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog