Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog

12. Output Devices

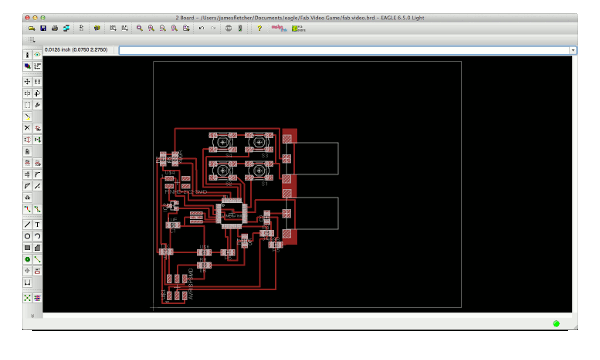

This weeks task was to "add an output device to a microcontroller

board you've designed and program it to do something". I liked

the video output board that Neil demonstrated and I liked the idea

of a challenge, so I decided to design a Fab Video Game board based

on this principle. Ideally I'd like the board to be able to

run old 8 bit style games from the 1980's eg. Tetris or Asteriods.

Based on my experience with the spinning top I decided that I needed

more FLASH than that available in the ATTiny44a, so I decided to

upgrade to the ATMega328 as we have those in stock here in the

Manchester lab. I also added 4 buttons for control. On

top of this the board would need an audio line output that would

feed the same monitor as the composite video out.

I didn't make it all the way to implementing Tetris, but the video

below shows a short demo running on my test board and a Pico PK320

projector. The image looses sync slightly as my line drawing

is currently taking slightly too long and corrupting a sync pulse.

FabLab video board demo

from James Fletcher

on Vimeo.

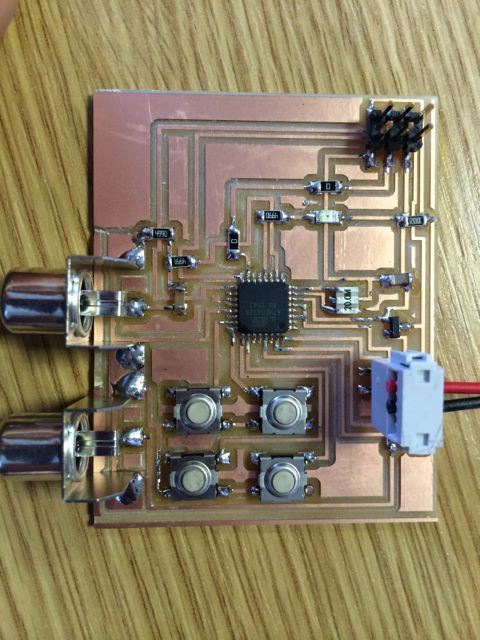

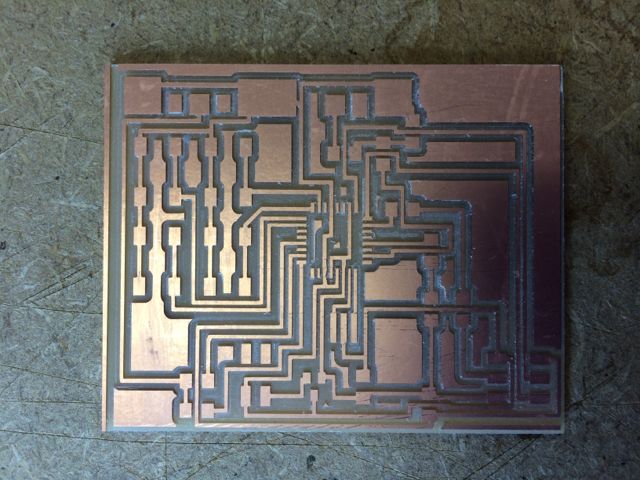

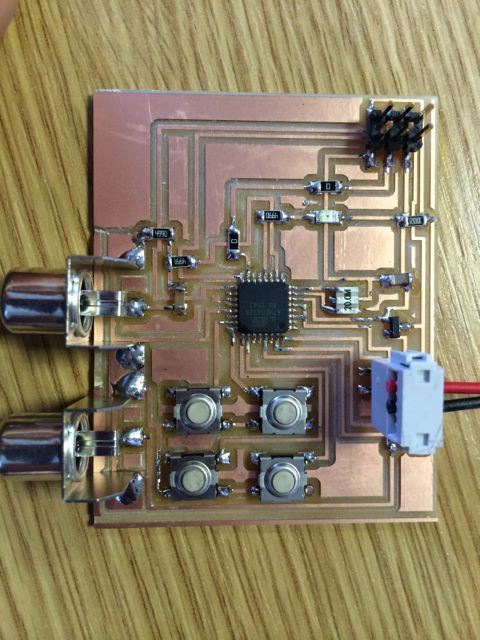

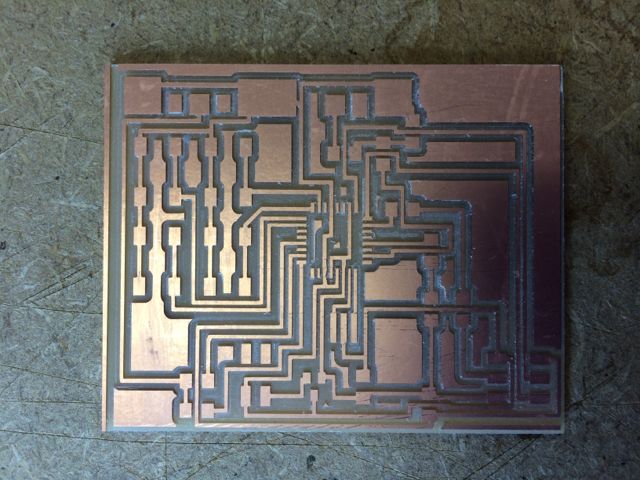

Picture of the final test board. I didn't have much time to

route it so I kept it simple. Ideally the board would have had

the RCA connectors along the top edge and the buttons along the

bottom.

12.01 Video Output

After looking at Neil's design I decided that the limiting factor

was the rate at which the state of the video output could be changed

by toggling the port pins in software. I decided that this

could be improved by using the SPI or UART pins to shift a bit

pattern out under hardware control. After looking at the

available byte framing on different hardware modules I decided to

use the USART in SPI mode for the following reasons:

- It supports 8 bit mode with no START, STOP or PARITY bits that

would corrupt the output.

- It has a 2 byte Tx FIFO that allows me to keep the Tx shift

register completely full with no gaps in the output bit stream.

- The baud rate will run right up to CPU_CLK/2

I used a PK320 Pico projector from Optima, as this supports both PAL

and NTSC I decided to stick with a NTSC format so that I could

initially start with Neils code to test the board. For my own

code I used NTSC timing info from http://www.astro.umontreal.ca/fantomm/Modedemploi/camera_guide_gene.pdf

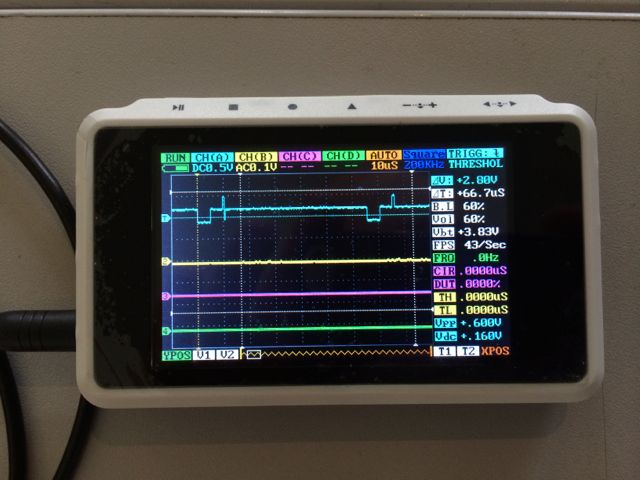

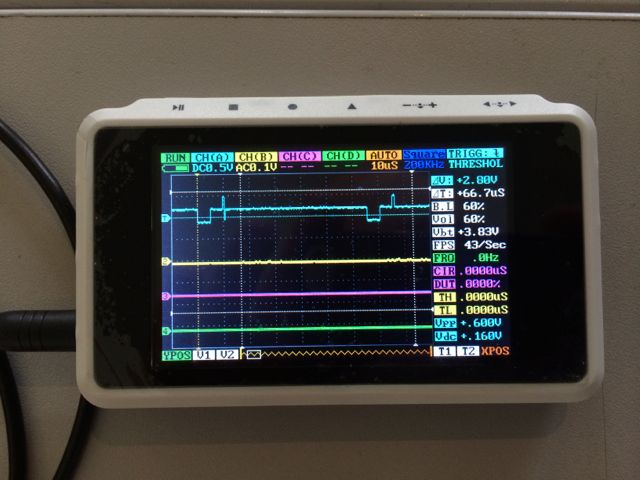

Early test pattern and sample video signal on scope.

12.02 Audio Output

The audio output is a simple line level out.

This is roughly 1v peak to peak into a high impedance (approx 10K)

input. I use a simple voltage divider from a single PORT pin

to allow me to generate square waves between approx 0v and

0.5v. I then use a small dc blocking capacitor to remove the

dc component of the signal and smooth it slightly. Although

this square wave is far from a perfect audio signal it approximates

to a a sine wave at the same fundamental frequency with lots of

higher order harmonics.

I then use Timer0 in CTC mode to generate a square wave on OC0A and

this to drive the audio.

I transposed the tune from the sheet music on http://www.gamemusicthemes.com/sheetmusic/gameboy/tetris/themea/Tetris_-_Theme_A_by_Gori_Fater.pdf.

Frequencies for notes were based on http://en.wikipedia.org/wiki/Piano_key_frequencies.

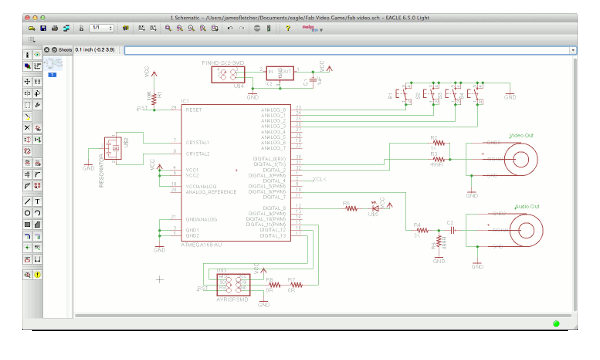

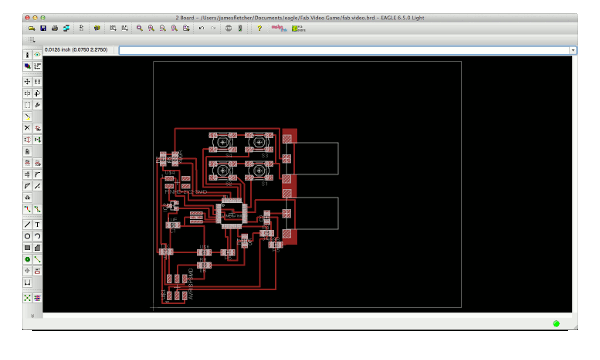

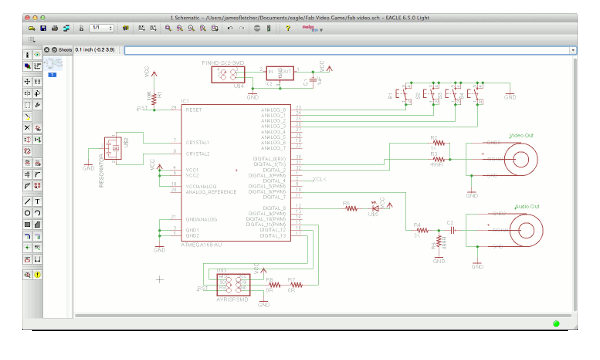

12.03 Design Files and Code

The Eagle schematic and

board files are

here. Along with the traces and interior png's.

The source code is here,

it will build and run on either a 16MHz ATMega168 arduino or my

20MHz ATMega328 test board.

12.04 Issues

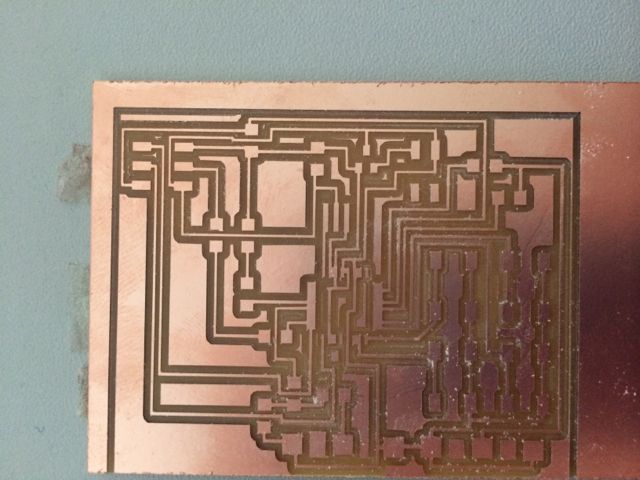

12.04.1 The Case of the Failed PCB Milling

I saw a 'fabduino'

project online and noticed that this provided Eagle files using the

ATMega328 and png's to mill with the standard 1/64th bit. So I

mistakenly assumed that the ATMega328 TQFP 32 part in the Eagle fab

libraries was millable with the 1/64 bit. I was wrong, my

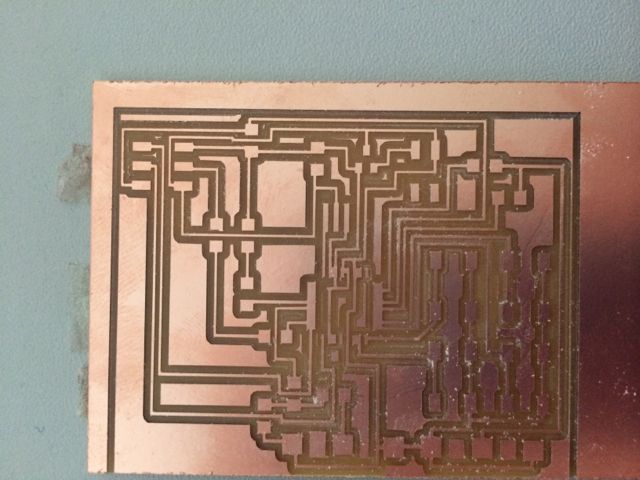

first attemp is shown below, note that not tool paths have been

generated between the pins of the TQFP package in the middle:

When I had come across this before I had found that a quick solution

was to lie slightly about the tool size to fabmodules. By

reducing the tool size slightly from 0.4mm to 0.3mm it will generate

tool paths for smaller gaps but all traces and pads will also be

slightly thinner as the tool will run closer to the outside boundary

of the pad or the trace. It's not the correct way to fix it

but it works sometimes as a quick fix. However for this board

I had to reduce the tool size right down to 0.2mm to get fabmodules

to generate all of the tool paths between the pads. This is

far too far from the real tool size and the final traces are too

fragile!

I investigated exporting at higher DPI from Eagle but this didn't

fix the issue. I also looked into using a smaller 10mil tool

and doing 3 passes on the Modela (10mill, 1/64inch and 1/32inch),

but this would have required more setup time than I had

available. At this point I ran out of time to mill boards

before the Easter break and so decided to prototype my code on an

Arduino whilst I investigated the problem in more detail.

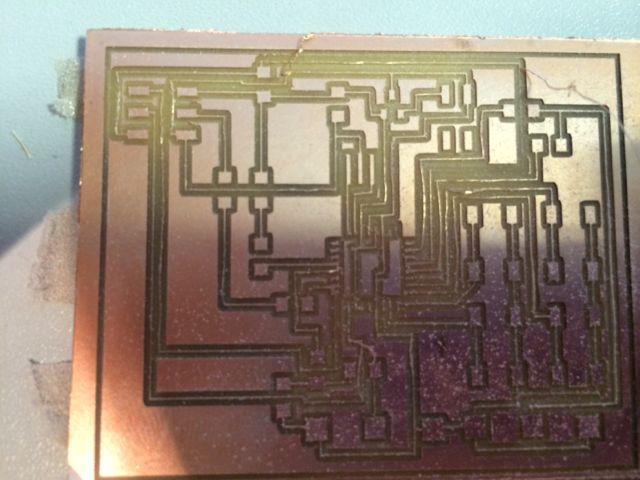

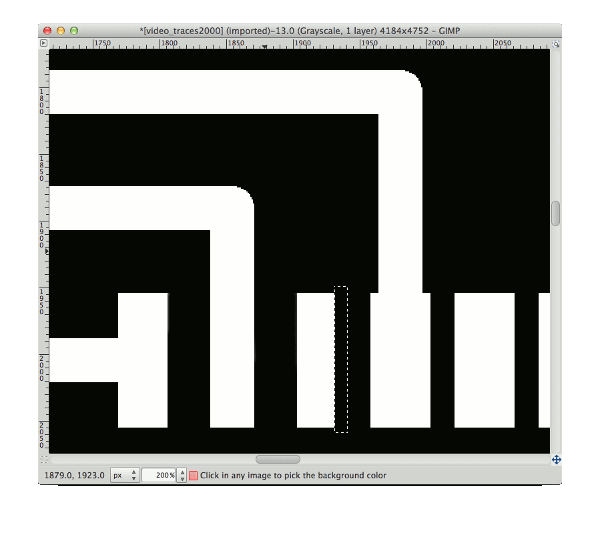

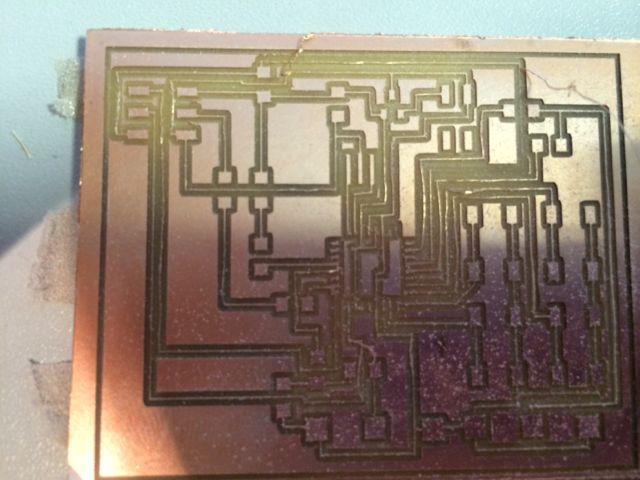

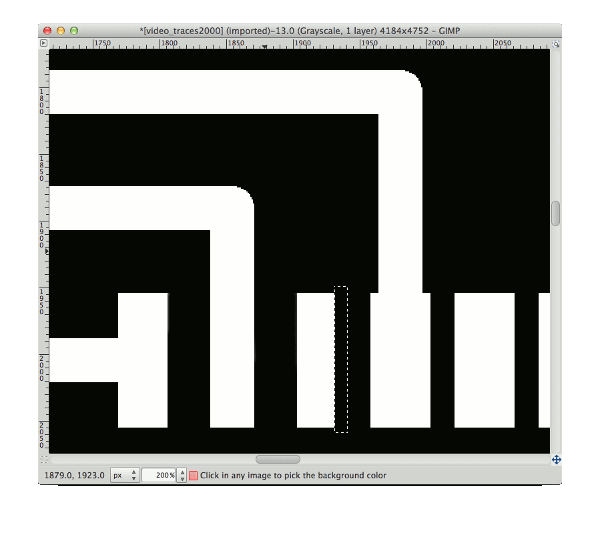

On closer inspection of the fabduino traces files I noticed that the

TQFP package didn't match the one in the Eagle libraries, the pads

were much thinner. Rather than create a new library component

and have to re-route my board when I swapped the package around, I

decided to manually edit the traces file in GIMP to remove some

copper between the pads.

This finally produced a millable board.

12.04.2 The Case of the Broken Fuse Bytes

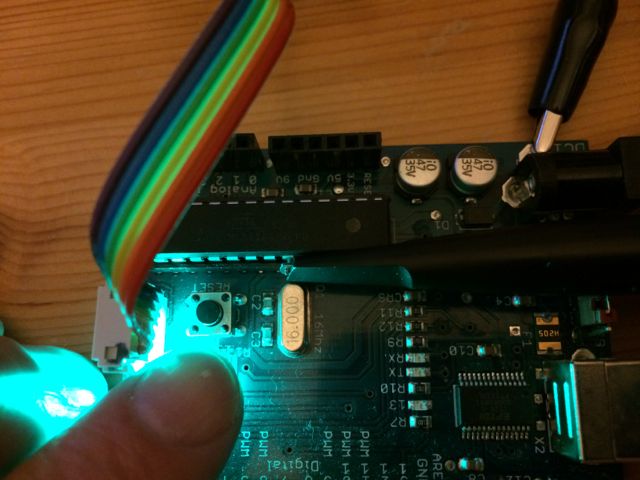

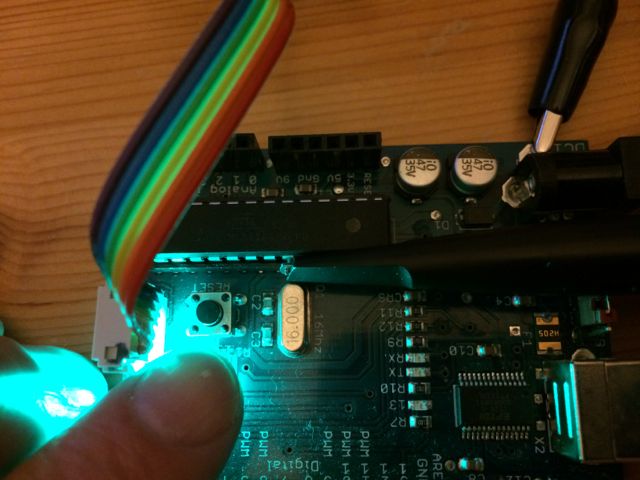

When working with the Aruino I managed to flash some broken fuse

bytes at some point. This left the ATMega328 in a state where

it wasn't generating an internal clock and so I couldn't flash it

with the FABISP. To get around this I fed a clock signal into

the AVR on the TOSC1 pin whilst trying to flash and slowed the

FABISP bit rate by changing the programmer line in the makefile to

the following:

PROGRAMMER = -c usbtiny -B 1024 -e

Luckily my portable scope had a 200KHz square wave output that I

could use for the clock and just touch the scope probe to the AVR

pin whilst flashing. This only needed to be done once to

program sensible values back into the fuse bytes.

12.05 Thoughts on IRQ Response Time

Initially I thought I would use irq service routines from Timer1

driving a state machine to generate all of the video timing

information rather than spinning in a polling loop waiting for flags

to change saying that a count had expired. This would allow

for a better separation in the code between the NTSC signal

generation and other work such as gameplay. However on

investigation I discovered that the irq response time is too poor to

meet the 5us timing requirements around the sync pulses. A

basic irq routine in C and compiled using avr-gcc with -Os comes out

at over 40 cpu cycles when you include the time it takes too enter

the isr routine. This alone is 2.5us at a 16MHz clock.

For this reason I fell back to using a polling method to check the

timer and generate the video signal.

With effort this could be improved. Some registers could be

reserved so that the compiler didn't use them. Then dedicated

asm routines could get rid of a large part of the function prolog /

epilog and avoid stacking registers. However any pre-compiled

LIBC code could still use these registers causing other issues.

Another option would be to use a hybrid system, polling within and

isr for the timing around the sync pulses and using a more

traditional isr approach during the displayable portion of the line

to allow easier singal generation / gameplay work division.

IRQ Response Time Analysis

// init

// Counts up in CTC mode

// No OC1x behaviour

TCCR1A = 0b00000000;

TCCR1B = 0b00001001; // CTC, 1 prescaler

TCNT1H = 0;

TCNT1L = 0;

OCR1AH = (_VIDEO_hsync_front_porch >> 8);

// initially set timing to full line width so we avoid any early

irq's

OCR1AL = (_VIDEO_hsync_front_porch & 0xff);

TIMSK1 |= (1<< OCIE1A); // Enable timer 1

compare A irq

ISR(TIMER0_OVF_vect)

{

VIDEO_state++;

if(VIDEO_state&0x01)

VIDEO_port = 0;

else

VIDEO_port |= VIDEO_high;

}

// Above IRQ code generates the following

assembly, numbers at the end of the lines are instruction cycle

counts.

90: 1f

92

push

r1

2

92: 0f

92

push

r0

2

94: 0f

b6

in r0, 0x3f ;

63 1 get SREG

96: 0f

92

push

r0

2 push SREG

98: 11

24

eor r1,

r1

1 zero into r1

9a: 8f

93

push

r24

2 push temp reg used by code

9c: 80 91 00 01

lds r24,

0x0100

2 load variable

a0: 8f

5f

subi r24, 0xFF ; 255

1 inc

a2: 80 93 00 01

sts 0x0100,

r24

2 store incremented variable

a6: 80

ff

sbrs r24,

0

1/2/3 skip if bit set

a8: 02

c0

rjmp .+4

; 0xae

<__vector_11+0x1e>

2 rel jump

aa: 1b

b8

out 0x0b, r1 ;

11

1 clear video port

ac: 01

c0

rjmp .+2

; 0xb0

<__vector_11+0x20> 2

ae: 59

9a

sbi 0x0b, 1 ;

11

2 set bit in video port reg

b0: 8f

91

pop

r24

2

b2: 0f

90

pop

r0

2

b4: 0f

be

out 0x3f, r0 ;

63 1

b6: 0f

90

pop

r0

2

b8: 1f

90

pop

r1

2

ba: 18

95

reti

4

Total 37 cycles

Simple code to toggle video out as we spin waiting for timer to

expire. This was one of my first test patterns.

/*

{

VIDEO_port_temp = VIDEO_port & ~(VIDEO_high | VIDEO_low);

VIDEO_port = VIDEO_port_temp | VIDEO_low; // set black: 0.3v

VIDEO_port_temp = VIDEO_port & ~(VIDEO_high | VIDEO_low);

VIDEO_port = VIDEO_port_temp | (VIDEO_high | VIDEO_low); // set

white: 1.0v

}*/

ToDo

- Finish Tetris

- Create a millable TQFP 32 part for Eagle

- Re-route the board with the RCA jacks and buttons in a better

placement.

- Optomise the graphics routines.

- Add font support.

- Add sprite support.

Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog