Week 3: Computer-Controlled Cutting

For this week, the assignment was to design, make, and document a press-fit construction kit.

All my life I had a great interest for bended shapes and since one of my greatest difficulties in college was the impossibility of presenting nice curved shapes, because of the difficulty they present, I chose to study the possibilities of kerf bending and what I could make with that.

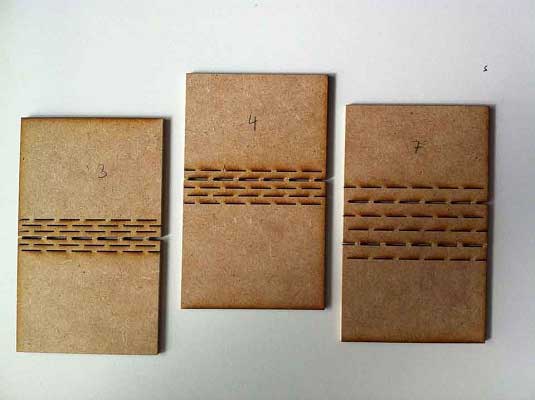

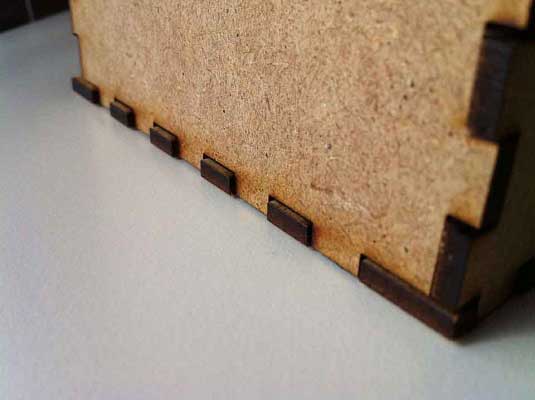

First of all I had to experiment with a pattern to try to bend the MDF I used. The following images are illustrative for the different line spacing I used.

This type of pattern is perfect to compromise the structure of a material, like wood, in order for it to bend. The first examples alternate between 3, 4 and 7 mm of line spacing for 6 row of lines in each piece of MDF. These was not enough because they broke as soon as I applied more strength on their bending.

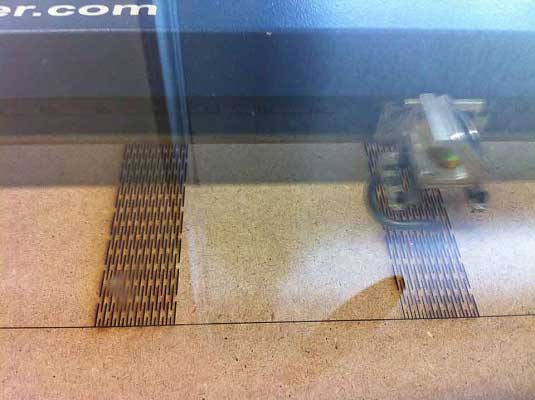

On the second image I used plywood instead of MDF, simply because I couldn't find more MDF on that time (ha ha ha), and this time, I shortened the line spacing to 1,5 mm. Indeed the 4 and 7 mm line spacing were not working for the effect I wanted so I knew I had to give it a lower value. I gave more lines this time and the effect was much better and so I thought: if I give it this line spacing that seems to be working perfectly but stills misses something, I decided to keep that line spacing and the next time draw more lines.

REMEMBER: always make the cuts in favor of the wood grain in order to take advantage of the material's elasticity.

Yes, my experiments were all broken :) !

This time I was praying that all went well, but deep inside I knew everything was going to turn out ok and you know what?

VOILÁ!!!

For my final experiment, I tried to press-fit some pieces together, but because of a bad day I was not focused on my drawings and that turned out bad. The pieces didn't fit at all ...

A really good piece of advice: if you are having a not so good day, NEVER, NEVER, NEVER CONTINUE STRUGGLING WITH YOURSELF!!! Go outside, breath fresh air, look in front of you and rest. After that you can go into FULL POWER mode.

Now comes my final project for this assignment: a Book!

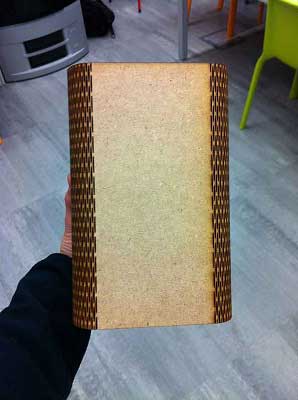

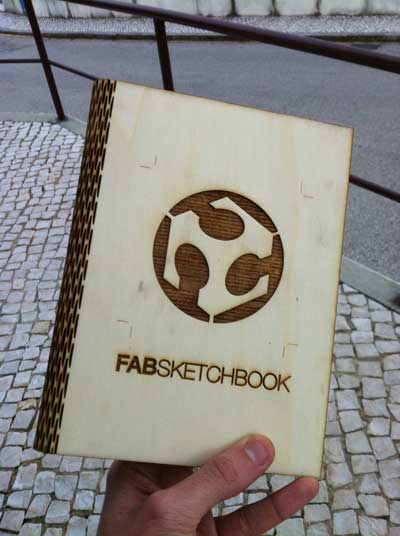

Because I'm a lover for sketchbooks, I decide to make one to use while I was attending this course. The next images are the final tests I made to check if my design was either cool or lame and I came up with this:

Here you can see the cover of my book which is entitled "FabSketchbook", but the fact is that it's not going to be a sketchbook. In my idea, a sketchbook needs to be really flexible and strong at the same time so that it can hold a lot of using. It cannot be made of plywood like this one. So I decide, instead of a sketchbook, why don't you create a book that will hold the pages for all of your projects in this course? Like a year book. Like a living document of my project's documentation. An album to remember all the good times and things learned troughout the semester. It's by far a better idea.

Using the kerf bending technic, I chose to continue my experiments until I got a nice result. This time I changed the pattern to wider cuts and gave a more even line spacing between them. I discovered that, depending on the material you're using, you need to check which measures fit best. Since this is plywood, the material itself is fragile and cannot hold an abrupt change in it's structure or otherwise it will break.

This plywood is 3.14 mm thick composed by 3 sheets of wood. The Logo and letters were engraved into the wood and I think the contrast between the wood color and the laser burned images is great. For the close I decided to kerf bend my way out of it as well and it came out nice too. For the final step of this project, I will press-fit the close as soon as I have time and change the line "FabSketchbook" to "FabYearBook".

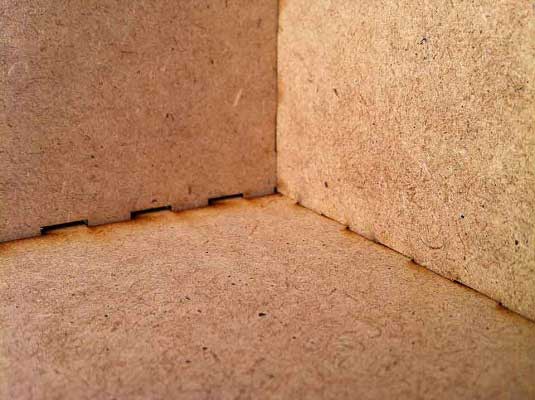

Here are more images of this project:

Final Output

This is a photo of my final project for this week:

A case for glasses and a book where I'll hold photos of all of my projects. A photogallery for Fab Academy's assignments.

Project's Files

Here you can download the project's files for this week:

Thank you all for watching!