|

For this assignment I decided to make a lavalier that will containg an electronic board 3mm x 1.7mm. I´ll connect it with bluetooth. This is the way the board will obtain the sensor´s information.

To start the molding, we need a brick of wax, a paintbush, a hammer, a drill and a good design! |

|

|

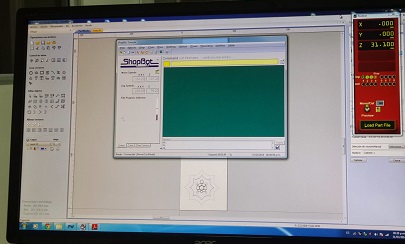

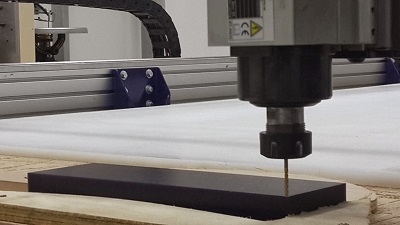

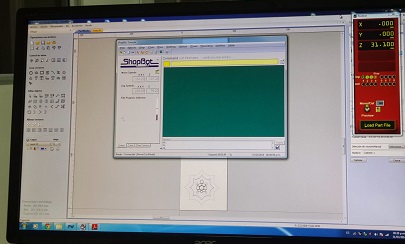

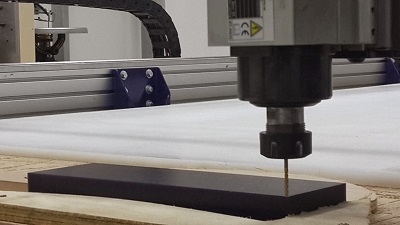

Such as for this assignment, its not usual to use cnc shopbot. But it´s fascinating because the cutting time reduces dramatically. Unfortunately, the smallest drill´s diameter is 3.17mm. It´s very important to fix well the wax brick. |

|

|

So, I settled the brick´s angle as zero, the origin point. Then I´ll make a tutorial explaining all the details.

The cutting time was 4 minutes only! |

|

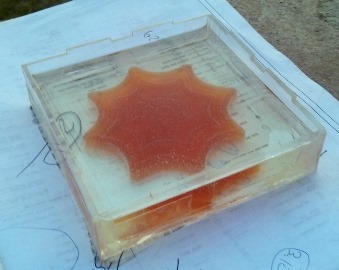

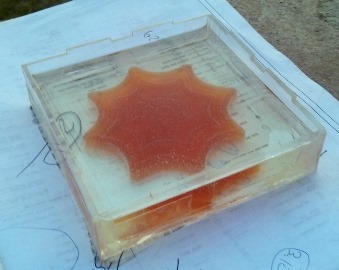

Here we are. Then I filled the wax model with rubber. I mixed these two components with equal amounts. |

|

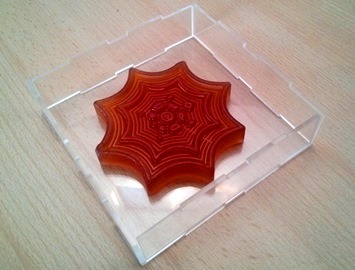

After 10 hours I´ve got this result. |

|

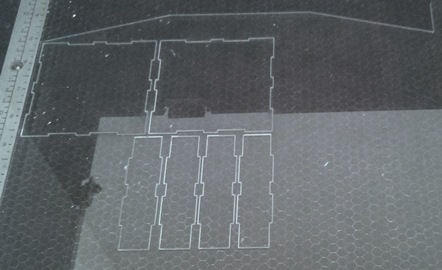

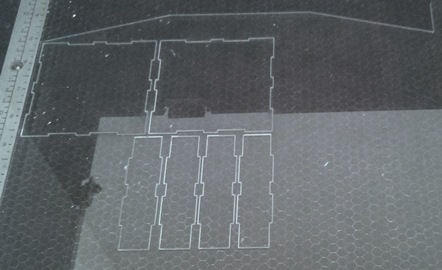

The next step is to make a box with laser machine for molding with liquid plastic "smooth-on".

Laser settings are: 30/100/5000

|

|

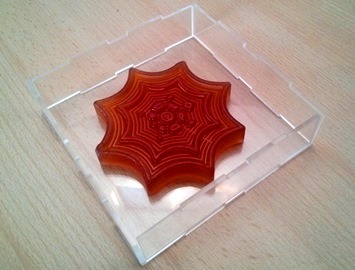

Now we´ve got the box. These two bottles contain a liquid plastic.

|

|

Here is the sequence. So, we mix these two components such we did with the rubber.

Wait for an hour to obtain the result. |

|

|

|

I recommend you to use th CNC shopbot for your designs. The Modela is able to cut the wax but its not able to work for hours cutting the models of all students. So, nobody was using the CNC Shopbot while doing this assignment. So, I used it!

|

|