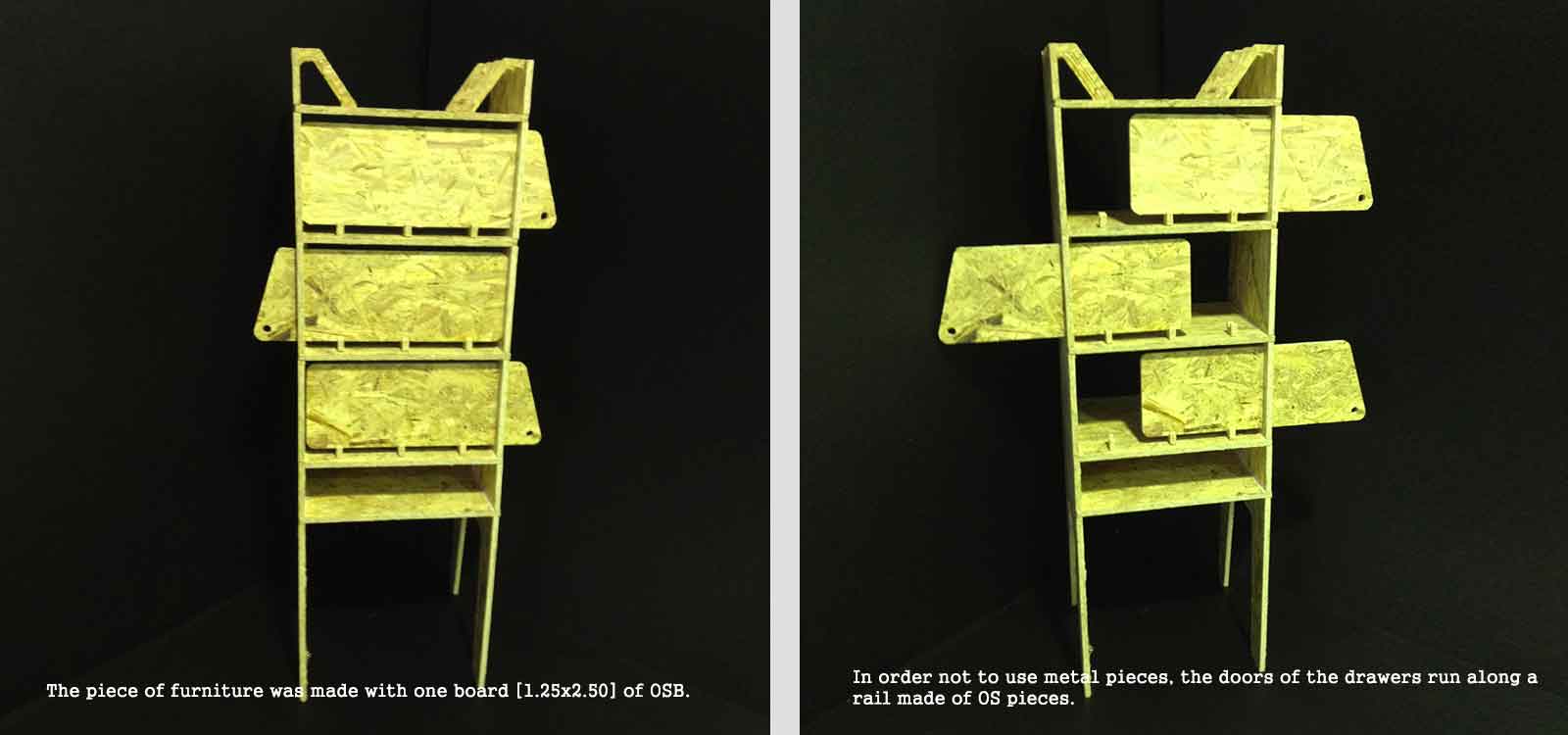

For this assigment, each one of us had one OSB [Oriented Strand Board] board to fabricate something big on the ShopBot CNC Milling Machine. The board was 1.25m x 2.50m. I decided to fabricate something simple but useful and I needed a wardrobe for my small room in Barcelona. I designed a piece of furniture that would fit my needs: 3 spaces for clothes, 1 space for small things and 1 space for books and documents.

Download the files here:

Furniture to mill [.dwg]

3D Model [.3dm]

For this assignment we had to design and fabricate something BIG. I decided to make something simple but useful that I actually need. Therefore I designed a piece of furniture in which I can keep clothes, books and other things. The size and design of it depended on the material available [one 1.25m x 2.50m sheet of OSB] and in order not to use metal pieces for the doors, I also designed other smaller parts.

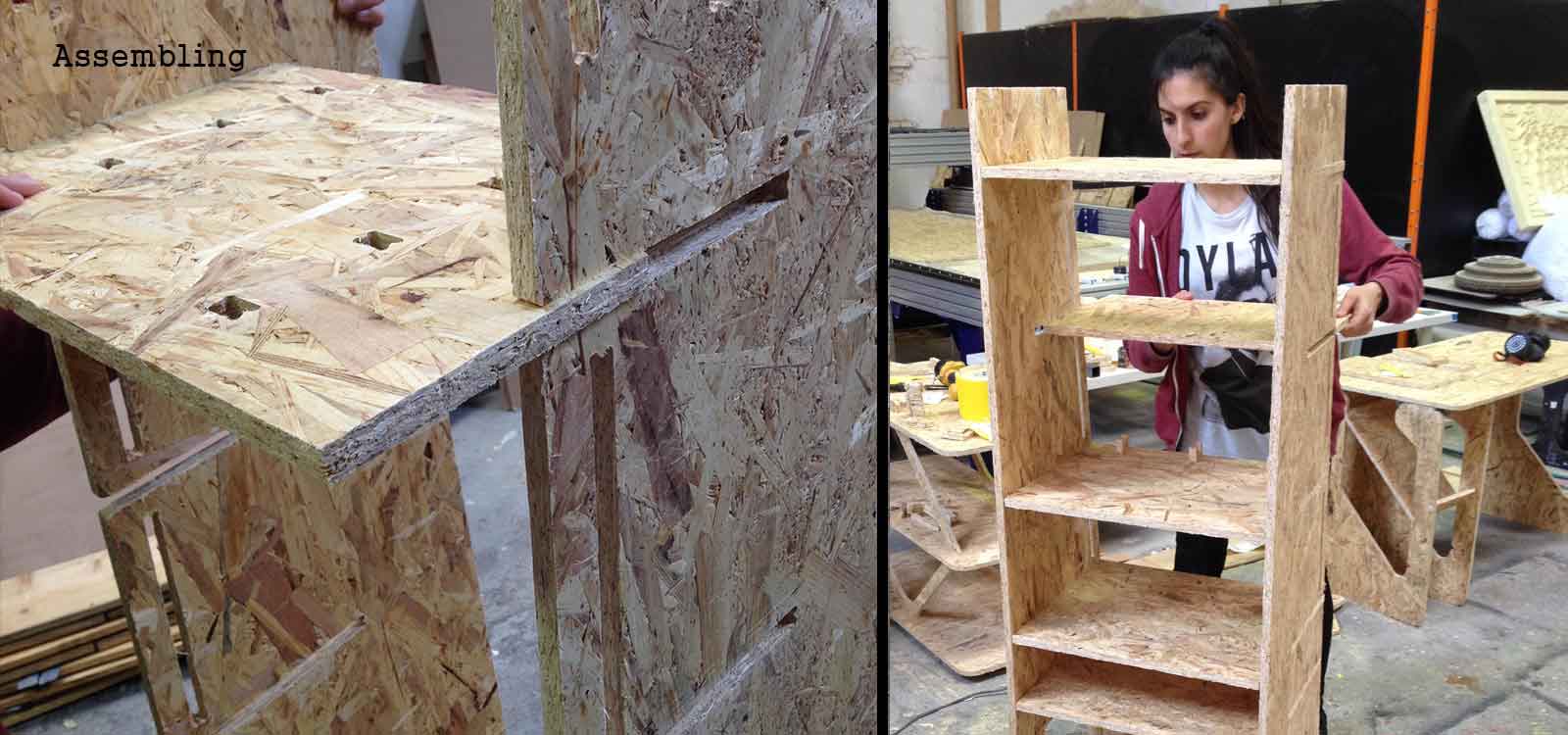

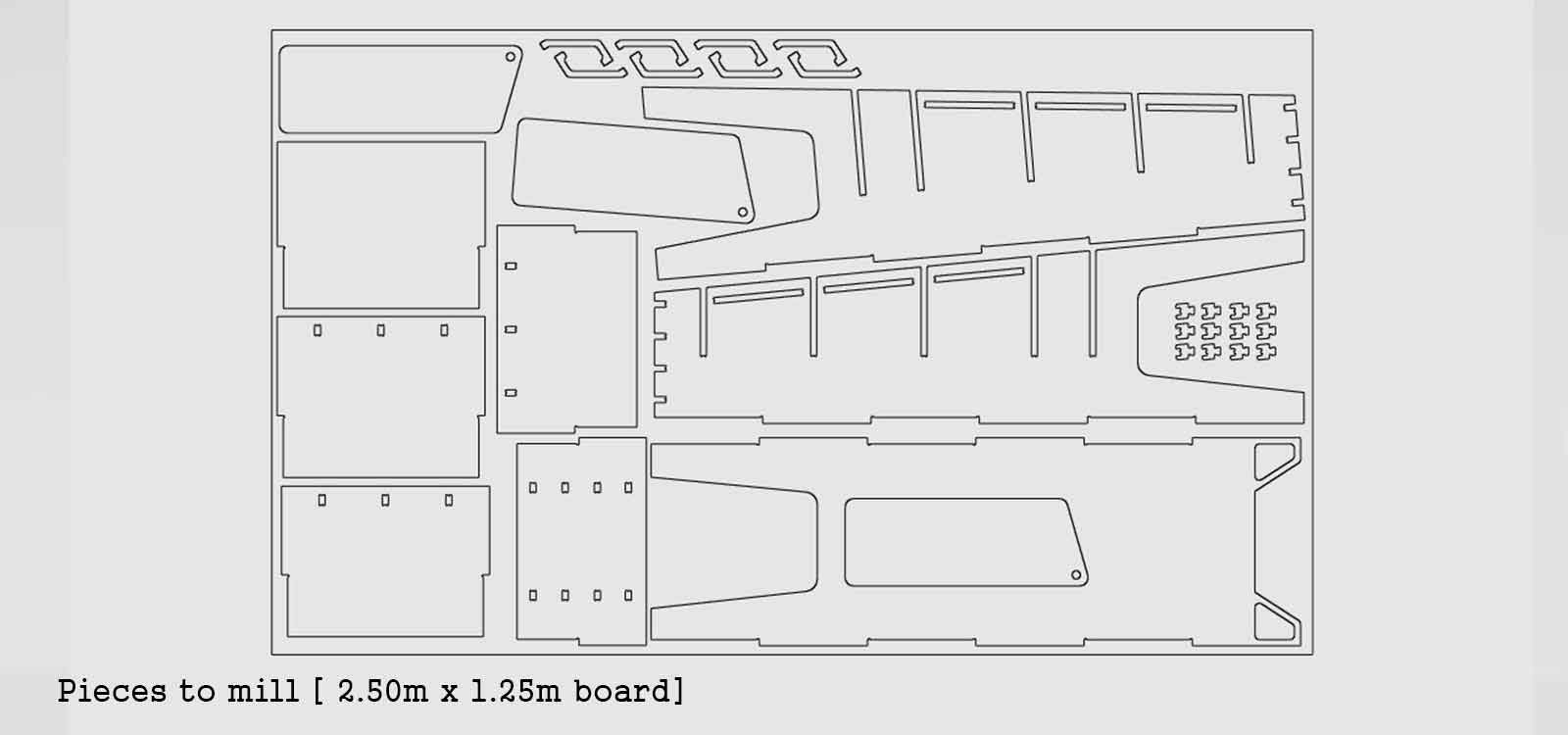

Once finishing the design, I made the assembly drawings and prepared the file to cut the pieces in the ShopBot CNC Milling Machine

I took the following steps to cut it:

01 Prepare the file on the Shotbot software in order to have it in 3 layers: holes for screwing the board, insided pieces and outlines with tabs to keep the pieces attached to the board while it is cutting.

02 Put the board in the machine's platform making sure that the surface is clean and smooth.

03 Set the machine ready. Find x,y and z.

04 Send the file to mark the holes.

05 Drill the screws on the board to fix it and make sure it doesn't move during the process.

06 Sent the file and wait for it to finish cutting. My file took 1 hour and 45 minutes to finish

07 Remove the tabs using a chisel and a hammer.

08 Remove the pieces and the board.

OSB is made by compressing different types of wood, so the cuts are not regular. After cutting I had to sand the pieces to make them fit.

At the end, the piece of furniture looked and worked in the way I expected.