1

2

3

4

5

6

7

The Liquid Slider is a light-weight content slider built for any device. It comes with an powerful API, a custom builder, and easily integrates with animate.css.

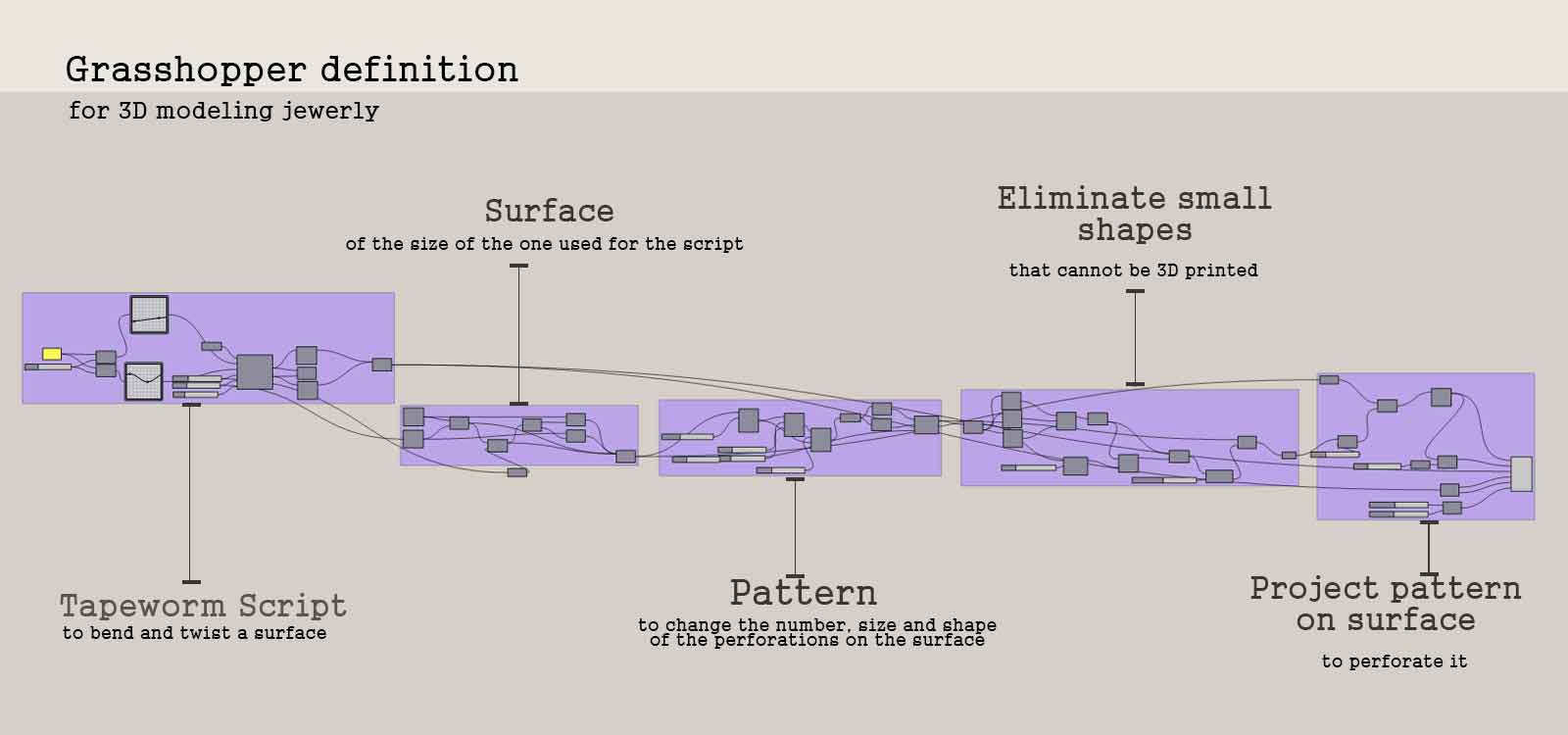

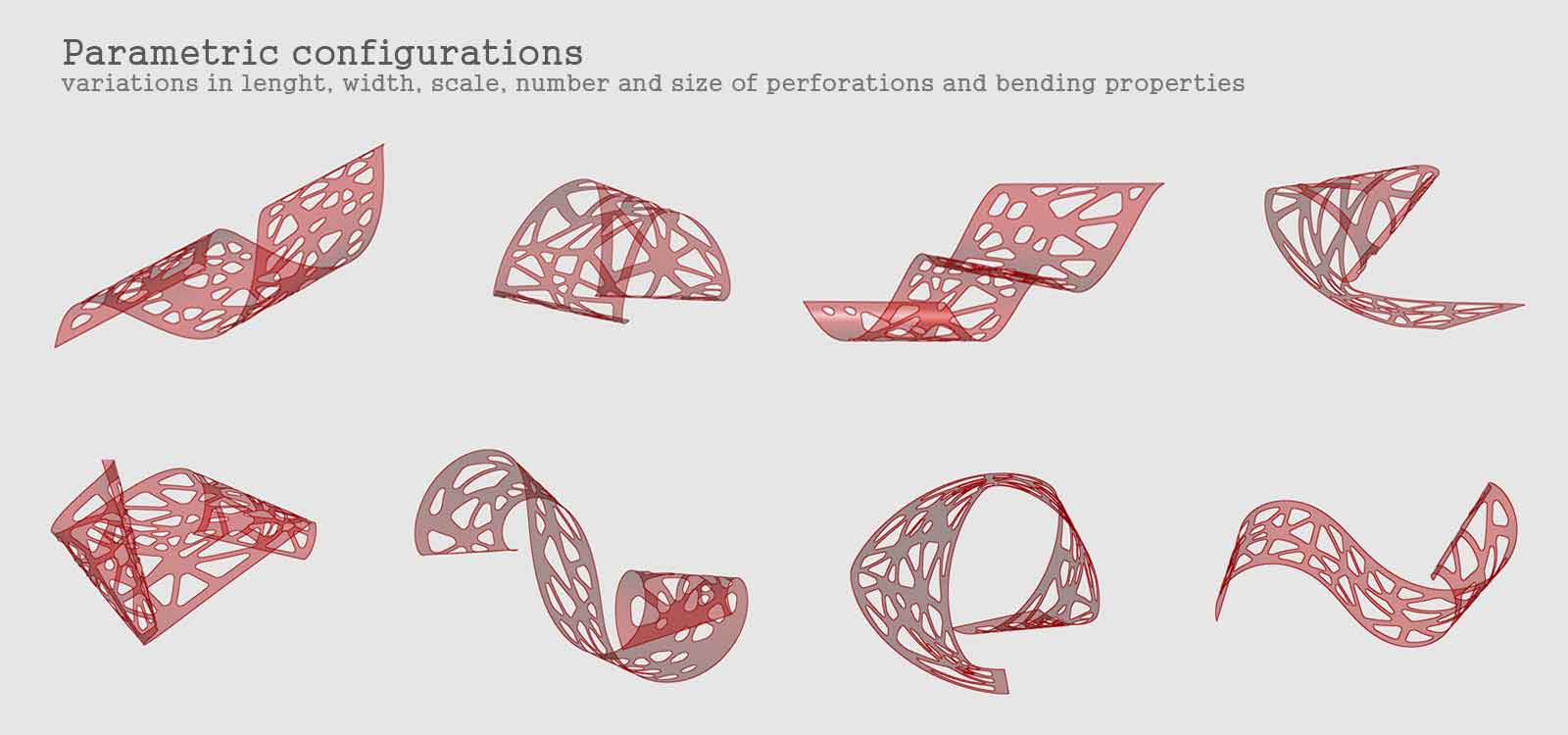

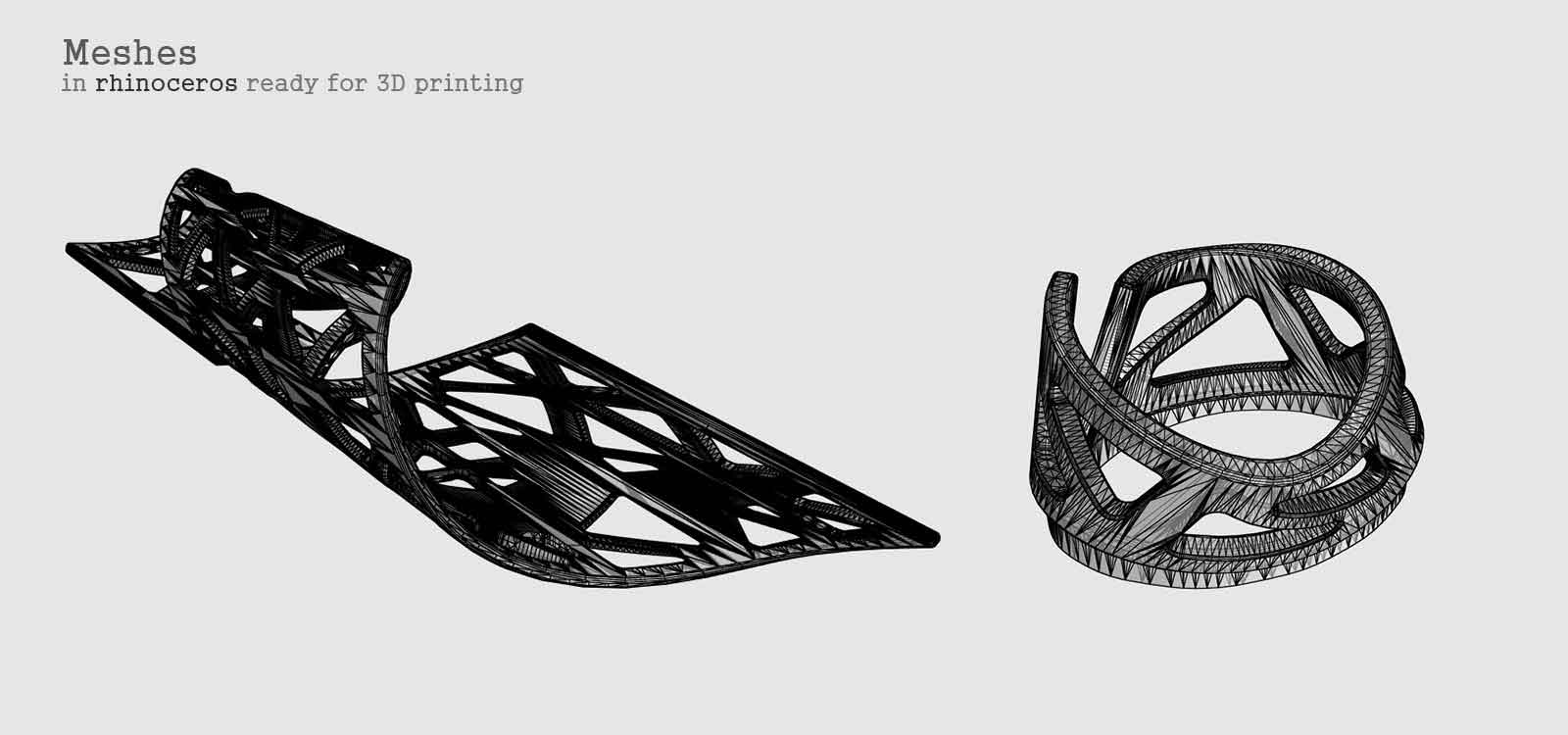

For this week's task, I developed a grasshopper definition based on the MN-tapeworm-script-v002 for designing parametric jewellery [necklaces and rings mainly]. The definition allows to bend a perforated surface in different ways, change its size, lenght and witdh and to also chance the size, number and shape of the perforations. By playing with the sliders you can define the shape you want to later convert it in a mesh to 3D print.

I made several mistakes during the process for the final results that explain in the following part.

Download the files here:

Grasshopper definition [.gh]

3D model [.3dm]

Mesh file for 3D printing [.stl]

I tested diverse shapes with different materials in 4 3D printers:

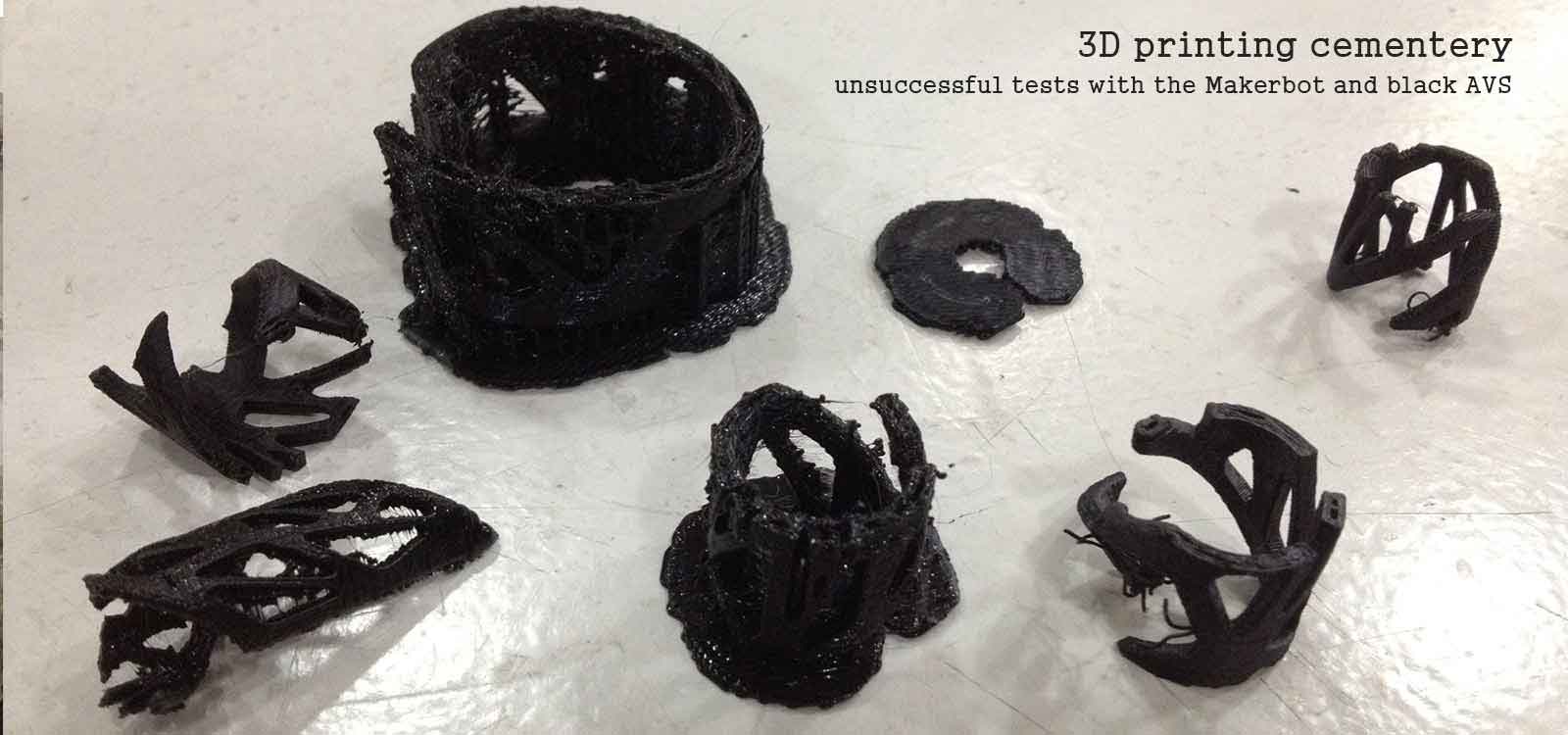

1. The MakerBot [material: PLA]

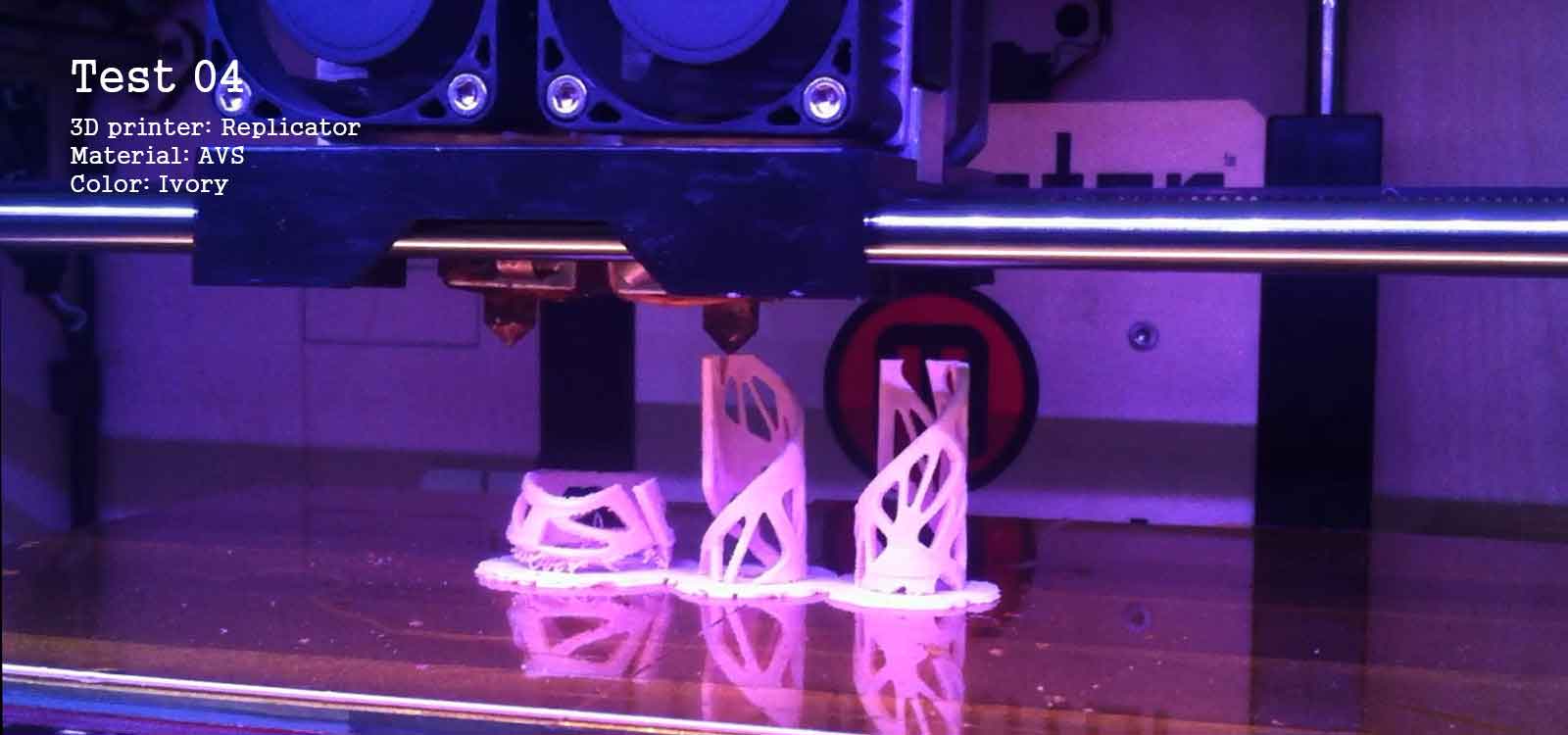

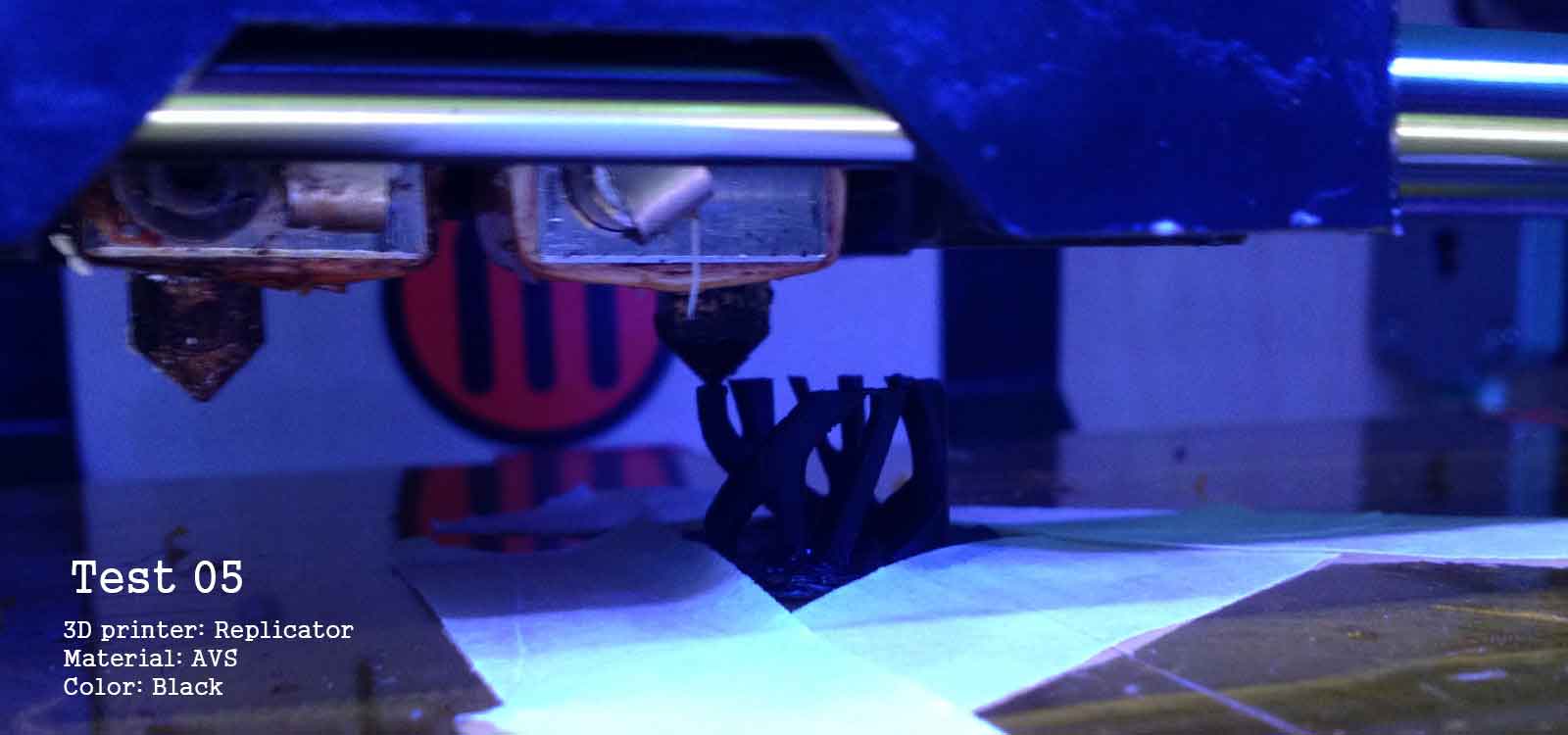

2. The Replicator [material: ABS]

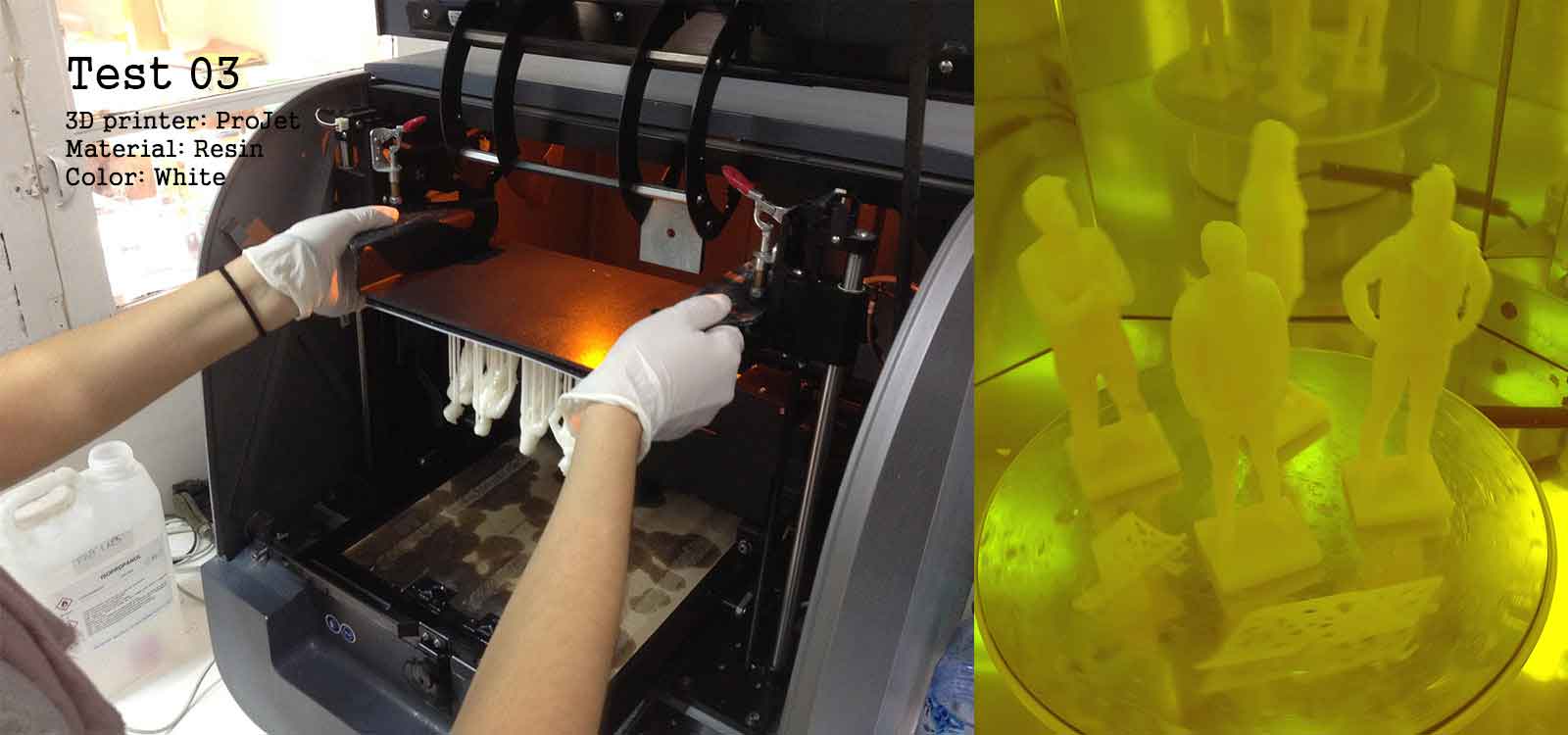

3. The ProJet [material: resin]

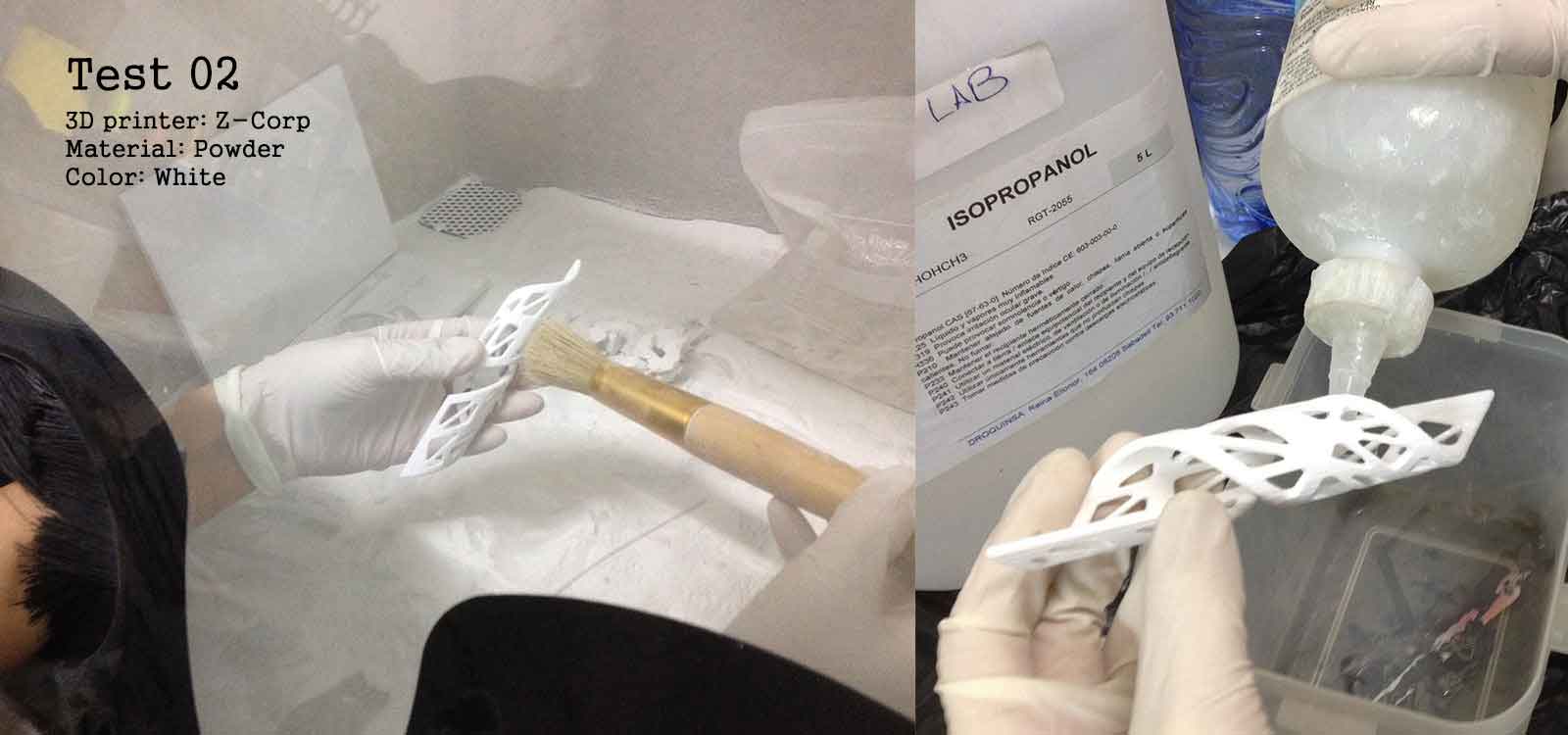

4. The Z-Corp [material: powder]

For this week's task, I wanted to make some pieces of jewellery. I developed a grasshopper definition based on the MN-tapeworm-script-v002 that allows to bend a perforated surface in different ways. By playing with the sliders you can define the shape you want to later convert it in a mesh to 3D print.

In order to have a smooth and clear 3D printed object, I had to pay attention to its tolerances and thickness. Therefore I had to change the grasshopper definition to remove the small shapes that could not be 3D printed or the ones that were too big and created thin parts that could brake

The first test was made on the MakerBot using black PLA .It didn't work. The object was too difficult to structure due to its twisted shape: the angles were too steep. To solve this, I cut the object in 2 pieces to give it a planar surface where to start adding layers.

For the following tests I chose to work with the the Z-Corp and the ProJet because I didn't have to cut the pieces. The material where they lay on is its own support.

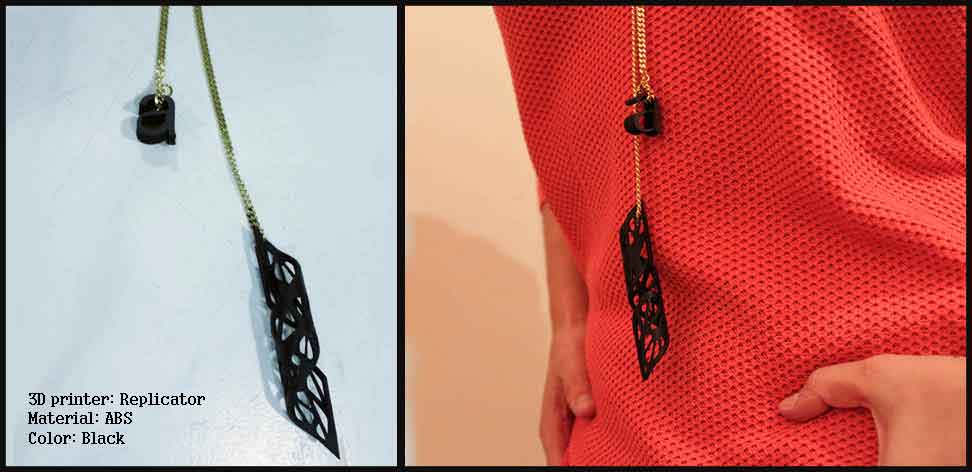

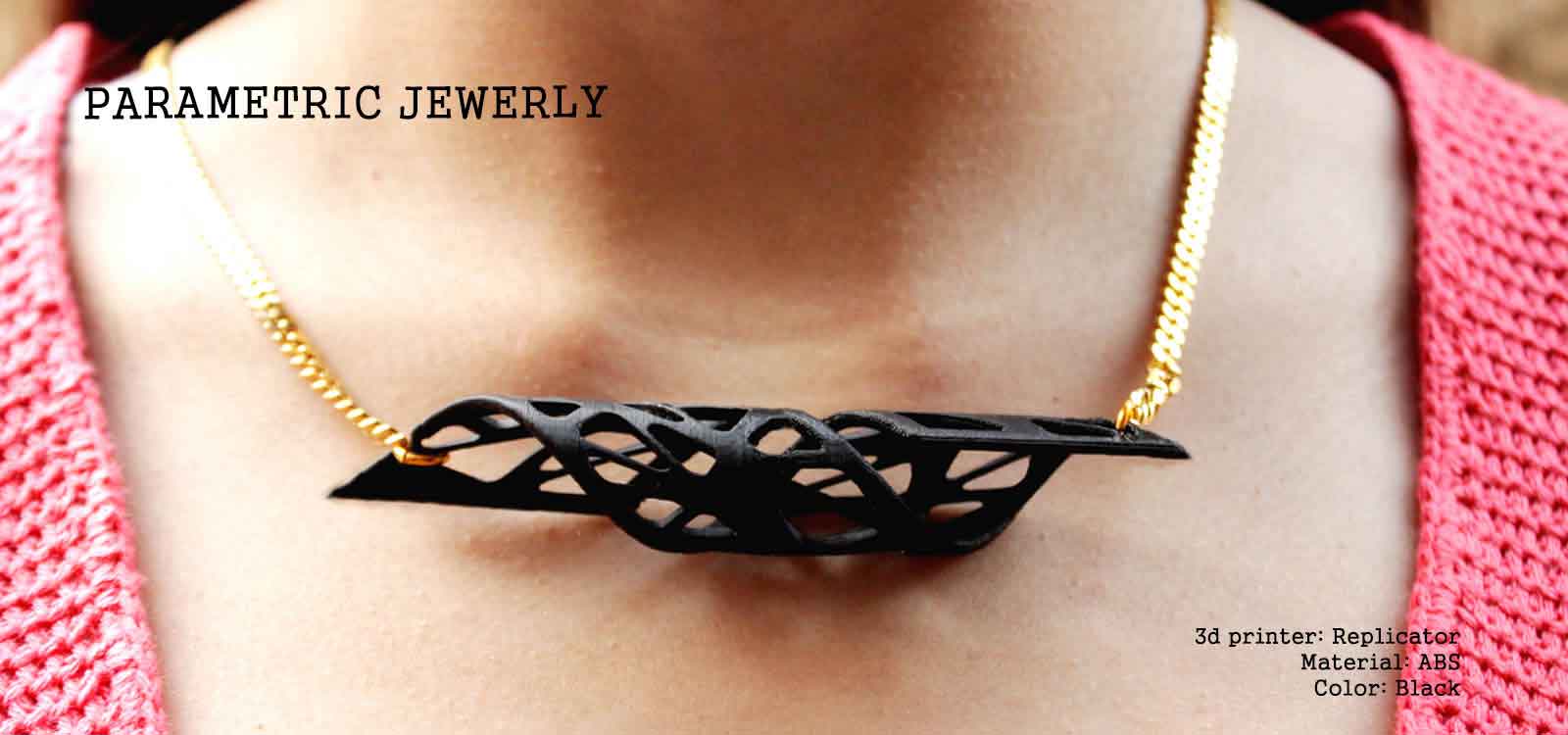

Finally, in order to not only have white objects, I used the Replicator with black ABS. The fist layer didn't attach very well to the platform (I couldn't find the exact degrees to heat it) so I had to tape it.

In conclusion, I can say that the 3D printers that work with layers addition, such as the Makerbot and the Replicator, perform better with geometries that have a stong or flat base. The heat and type of plastic filament that you use in them, also determines the way it works. On the other hand, the Z-Corp gave very good resolution to my objects but they are more fragile than the ones made of PLA, ABS or resin. To me, the best 3D printer was the Projet but also that one with a longer printing process