For this assignment, I decided to build the lounge chair of my project in 1:6 scale. This chair does not have a support because it is supposed to be screw-connected to the metal frame of my pedaling piece of furniture.

LOUNGE CHAIR 1.0

Design

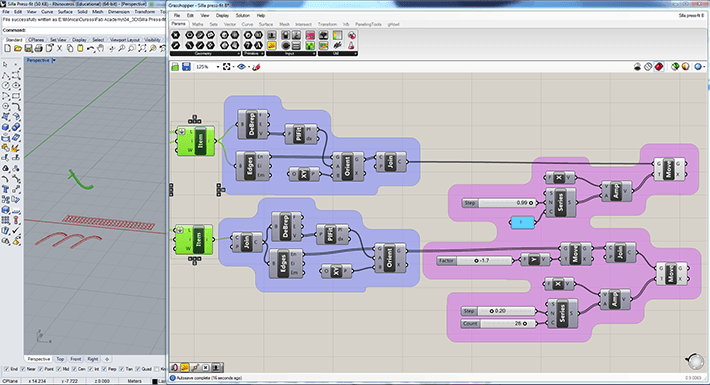

I added some components to the definition I made in Grasshopper, so I could have the pieces ready to cut. In this case, all the pieces and profiles are the same, so I did not need to use number tags.

Materials and equipment

_CNC Laser Cutter: Epilog Legend 36EXT

_3mm MDF board

_Caliper

Fabrication

I used the caliper to measure the thickness of the MDF board, the result was 2.8mm. Then I did some tests in the laser cutter to see if the press-fit was working properly. The best result was 2.65 mm for press-fit joints.

I used the properties that appear in the laser cutter for wood (Speed: 30 / Power: 60 / Frequency: 500), they worked very well. I considered 900 x 600 mm of work area, according to the laser cutter we have in the Fab Lab.

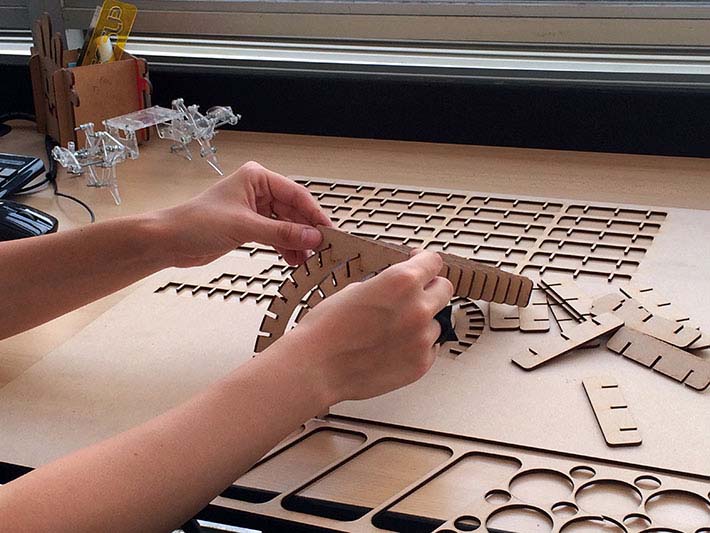

Finally I joined the pieces of my chair as a puzzle, it was a little hard, so I think I should have used 2.70mm for press-fit joints. It was a simple process; however, I realized the design was not ergonomic and it did not seem comfortable at all. Therefore, I decided to create a new design in Rhinoceros and Grasshopper and repeat the whole fabrication process.

LOUNGE CHAIR 2.0

Design

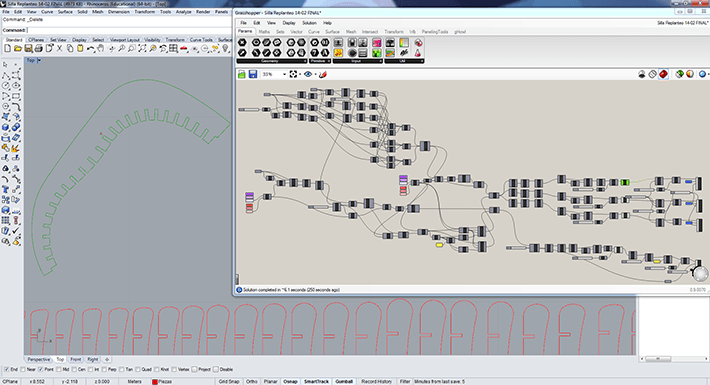

I drew the profiles for my new chair in Rhino, set the curves in Grasshopper and created a new definition for it, very similar to the previous one. The new definition includes number tags because this time all the pieces are different.

One of the tutors suggested that I could use this online software for chairs next time:

http://www.sketchchair.cc/

I have not used it yet, but it seems practical and very helpful.

Fabrication

I repeated the whole process I did with the first chair. However, I have to admit that I had some drawbacks this time. I did some tests with small circles just before cutting my pieces, but the laser cutter was not cutting the MDF board; although I increased the power and speed, it did not cut. It was very strange because the MDF board I took had the same thickness as the last one (I used the caliper to confirm it). So I tried with a different board and it worked perfectly, in that moment I realized the former MDF board was slightly moistened, that is why it was not being cut. In the meantime, the lens of the laser cutter were cleaned and the machine was calibrated because we thought that this could be the problem. When it was already working well, I did some tests for the press-fit joints (2.75, 2.70 and 2.65mm) and the best result was 2.65mm. Last time it was 2.70mm, so now I know I should do different tests for each different board, even if I am using the same material and the same properties.

Total number of pieces: 29

MDF board thickness: 2.80 mm

Thickness for press-fit joints: 2.65 mm

Speed: 30

Power: 60

Frequency: 500

Raster (number tags): 100/100

I think I can continue improving the design, and since it is parameterized, I just need to change the control points of the curves in Rhino in order to change it.

OTHER STUFF

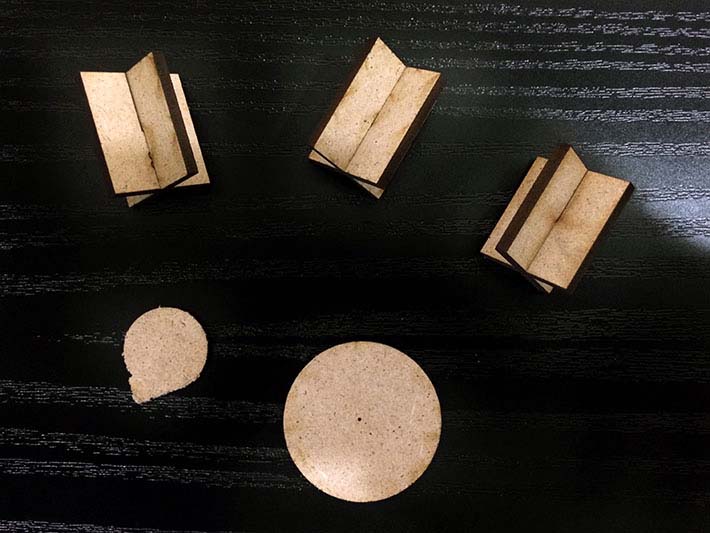

These are other objects I have fabricated with different materials: cardboard, acrylic and leather.

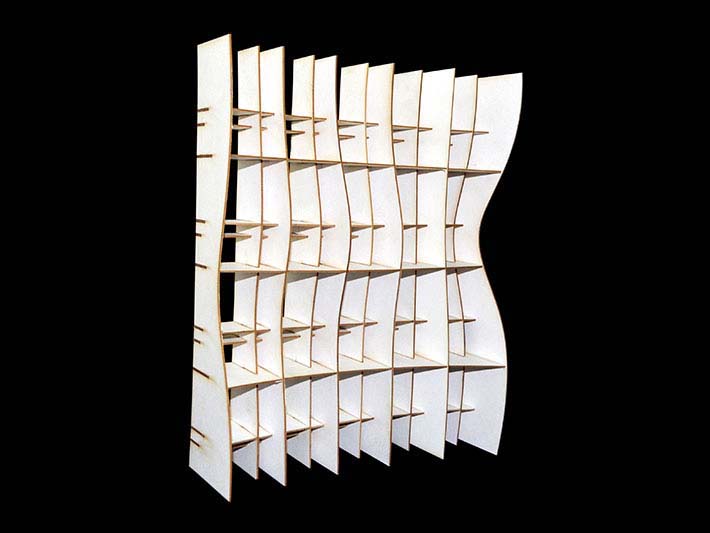

Generative shelf model

Carboard / Press-fit / Parametric design

Butterfly necklace

Black leather / Voronoi definition

Dragonfly wings earrings

Acrylic 2- 5mm

Wings ring

Acrylic 3mm / Cutting + Raster