>> Week 11, Apr 9: Composites

Design and make a 3D mold (~ft2), and produce a fiber composite part in it

|

Before this assignment, I did not know anything about composites. However, it was very interesting for me due to the possibilities they provide. First, I observed how my course classmates developed the composite experiences in FabLab. They all did it by using moulds. I was really interested in the use of a vacuum bag, since I hadn’t seen it before. Unfortunately, I run short of time and the final project rush did not allow me to complete this assignment as I would have liked. I could not perform the vacuum sealing. Below, I report my progress in this assignment.

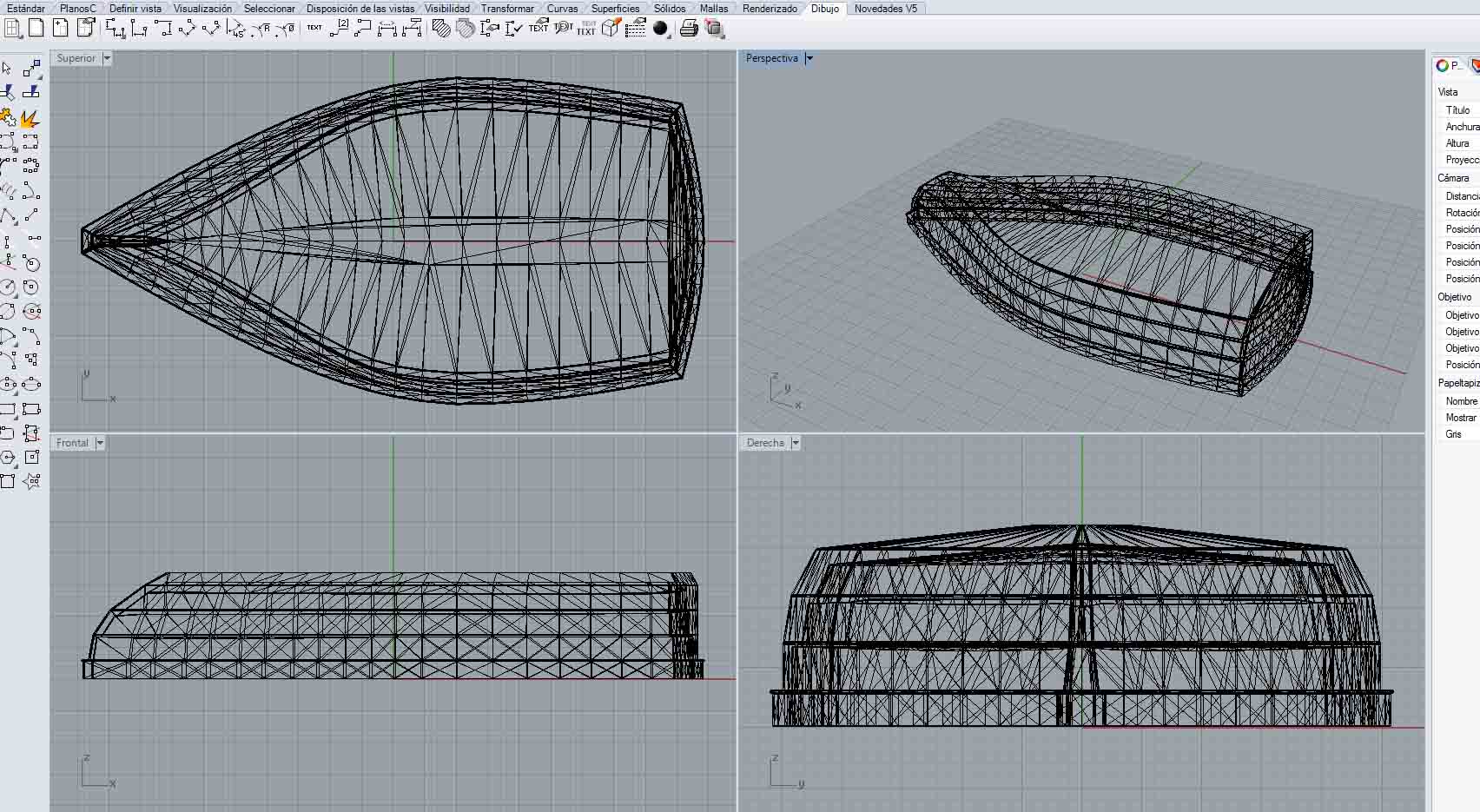

| My goal was to develop the fuselage of a boat. I worked the model in 3D. |

|

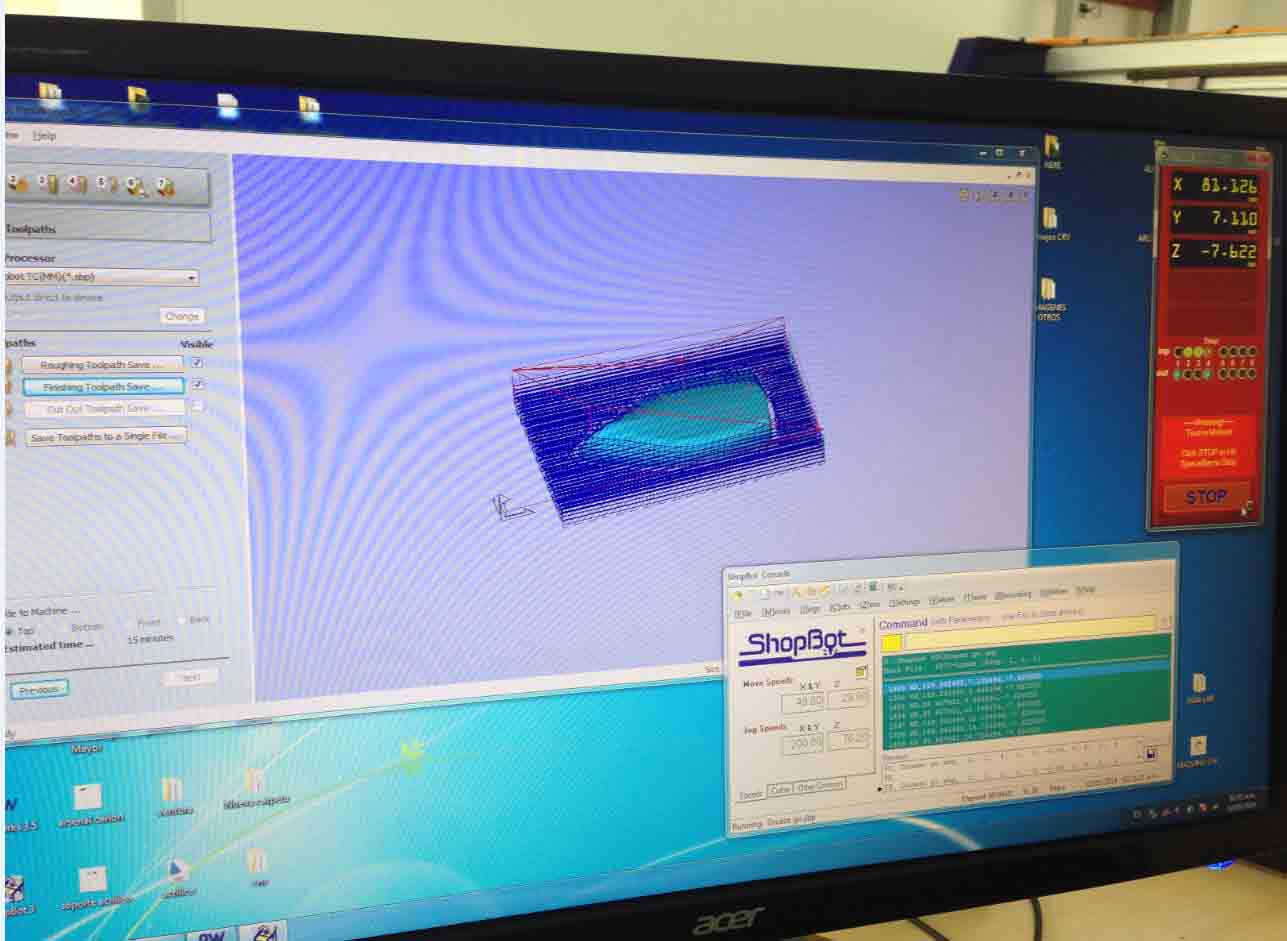

To obtain the mould, I used the ShoBot, with PartWorks3D software. |

|

During the first execution, I worked with a 18mm MDF. Unfortunately, the mould resulted small. |

|

In order to create a larger mould, I put two MDF boards together to obtain a thickness of 36mm and then I plotted the mould again at a higher scale. |

|

After the smoothing and finishing processes, I obtained the mould I wanted.

|

|

I prepared the resin and fiber to be used. |

|

|

|

The problems started when we started the tests of vacuum sealing. We manufactured the system to connect the vacuum pump to the bag and then, with an air valve, seal the vacuum. However, we didn’t succeed with the sealing. When we disconnected the bag from the vacuum pump, air entered the bag again. I realized we needed to replace the bag’s edge seal by using a special silicone for this purpose. Unfortunately, I did not manage to obtain the silicone used to seal the vacuum bags. I could not complete my assignment. (Below, pictures of the vacuum sealing tests). |

|

Another attempt. Due to the lack of sealing silicone for the vacuum bagging. I went for the molding method.

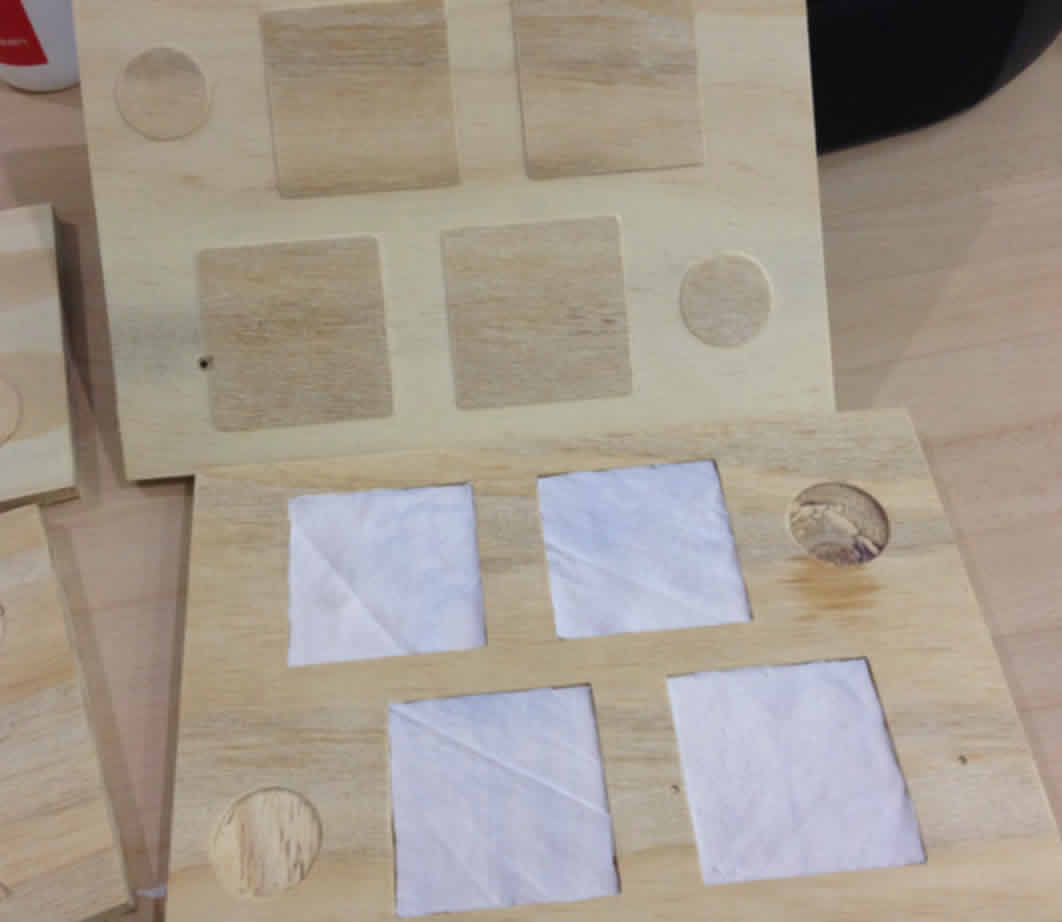

I manufactured another mold Molds parts fit each other

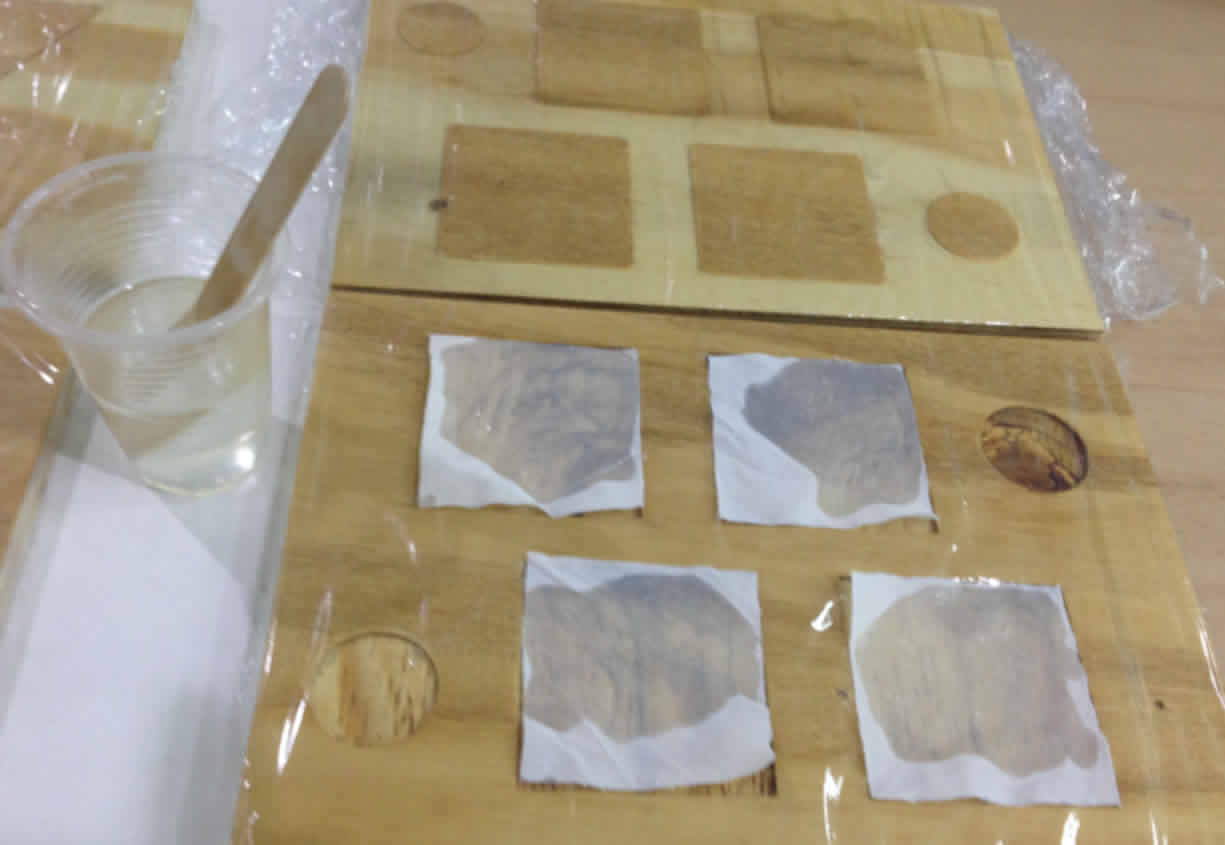

I prepared the fiber to be used. "Tocuyo" a cotton fabric

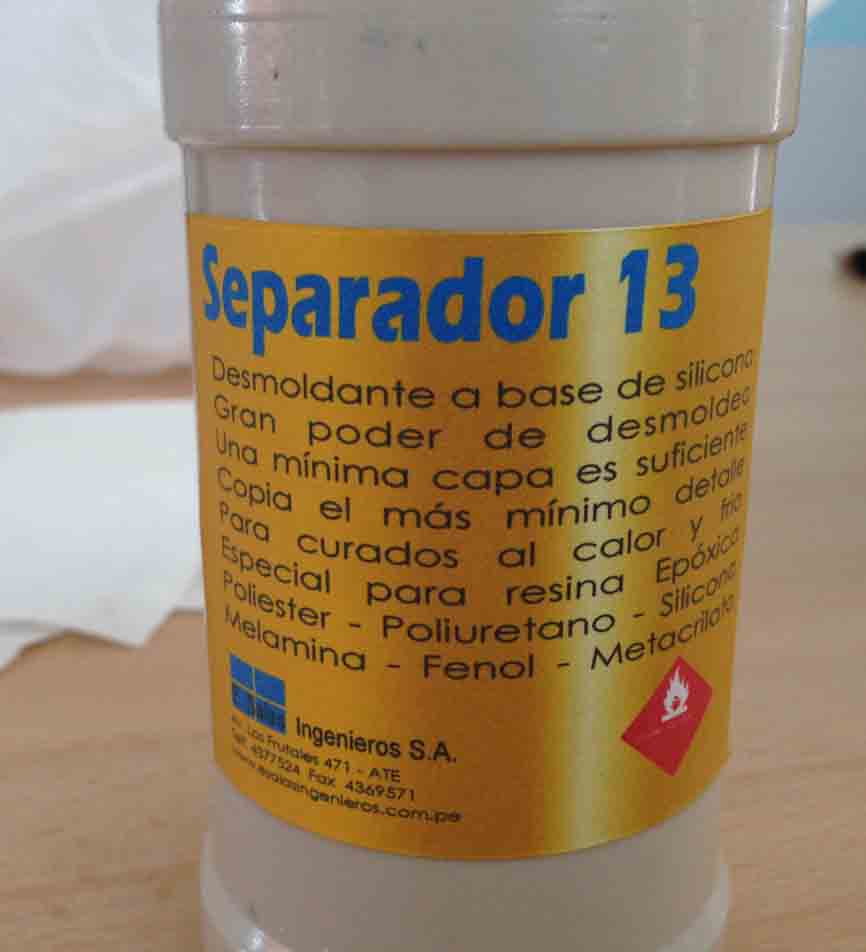

I applied the release agent to the entire mold and used film to separate it from the resin.

I prepared the resin to be used.

I applied resin and fiber to the entire mold

Then I fit one mold in the other one and wait to dry Unmolding and the composite is done.