>> Week 05, Feb 26: 3D scanning and printing

>> Design and 3D print an object (small, few cm) that could not be made subtractively

>> 3D scan an object and print

Design and 3D print an object that could not be made subtractively

For this assignment, I explored the application of 3D design and printing in areas related to creative professions different from engineering; for this purpose, I managed to design a non structured object, product of my imagination, trying to use the most simple and natural creation process.

Materials:

- OSX laptop

- Sculptris Software

- NetFabb Software

- 3D Printer: MakerBot Replicator 2x

- 1.75mm thickness ABS thread

|

Some images of the design process are shown below:

|

All begins with a sphere |

|

The sphere is modelled |

|

Alter some details, the design is ready, and it is exported in .OBJ format. |

|

I tried to optimize the design with Meshlab software; however, I did not obtain good results and I used other software. |

|

Finally, thanks to Netfabb software, I optimized my design, and I adjusted the size and reduced the faces amount considerably. This software allows exporting in format .STL and .OBJ |

|

The printing process was performed with an ABS thread, 1.75mm thickness. |

|

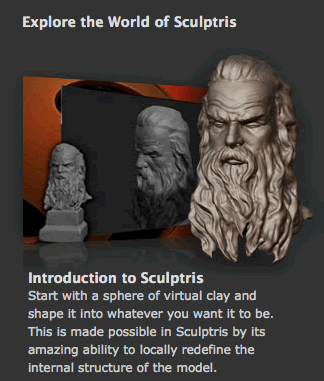

Using MakerWare software, by MakerBot, I prepared the final file for printing. The file obtained by this process has a .x3g format. |

|

Quality parameters: |

|

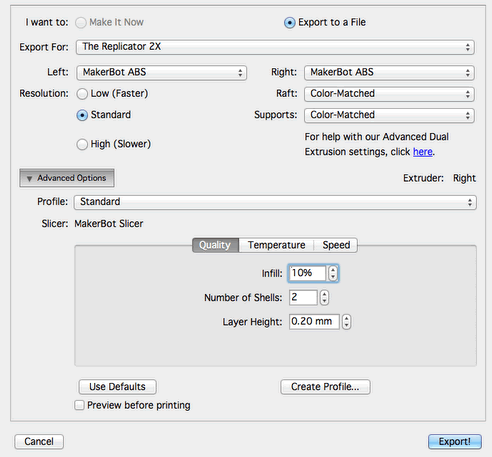

Temperature parameters: |

|

Speed parameters: |

|

Finally, the .x3g file is sent to the 3D printer and the printing process starts. The time elapsed between the printer warming and the final print is 1:30 hours. |

See video

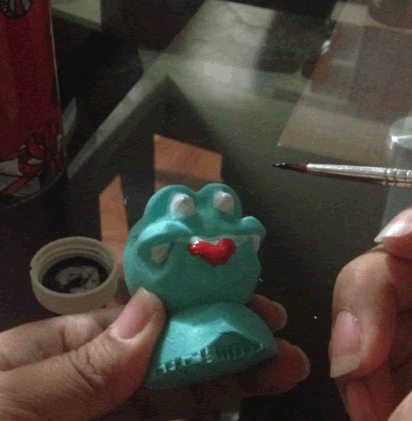

It was a great surprise when I showed my creation to my little 5 year old daughter: she adopted my creation immediately and started to customize it, she dressed it with doll clothes! Some pics here:

|

|

|

|

|

3D scan an object and print

For this section, I researched 3 scanning and printing alternatives in a MakerBot Replicator 2x printer

- Scanning with Creaform EXAscan professional scanner and proprietary software

- Scanning with Xbox Kinetic and demo software: Skanec

- Scanning with Roland Modela and Dr. Picza software

|

We obtained the samples from a professional scanner; the results were obtained very quickly. However, the high cost implies a great limitation. Therefore, I explored other alternative for scanning. |

|

I also made scanning tests with Xbox Kinetic, using the demo version of Skanect software. I obtained a satisfactory result in a short time. However, the software demo version limits the scanned object to 5000 faces, which reduces the final result quality. |

|

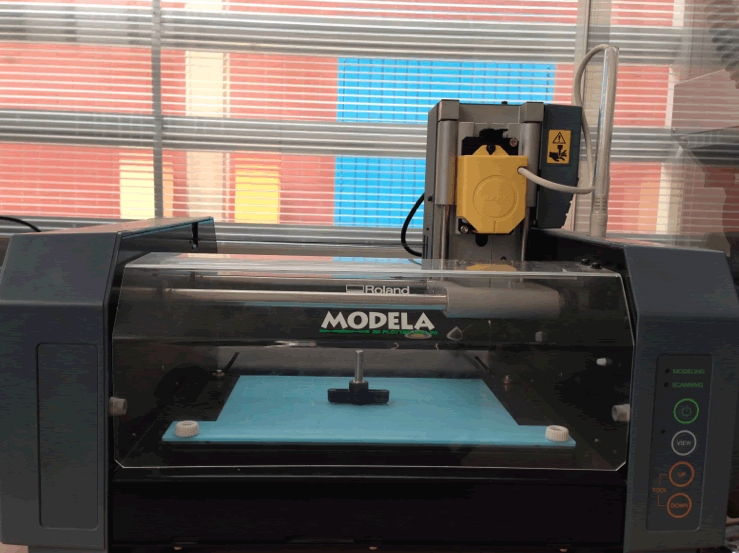

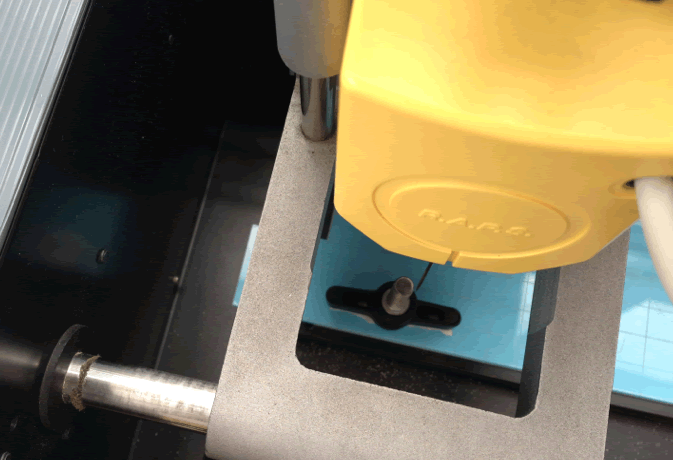

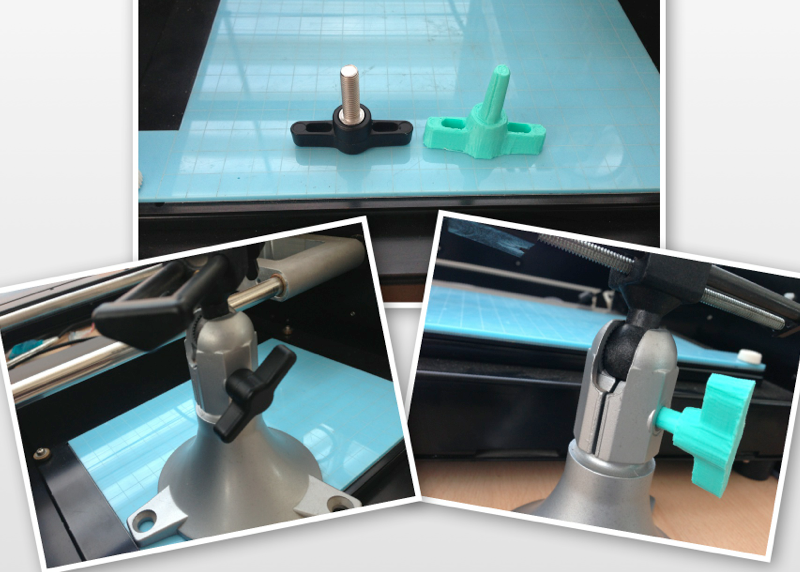

Finally, I scanned an object using Roland Modela printer and Dr. Picza software (this software only works in Windows XP) |

|

Fix the object tobe scanned adequately (with help from a doble contact strip). This is important, since the scanning is made by means of point scanning. |

|

Configure the area to be scanned. This is important, since the scanning process is extremely slow. |

|

The scanning process of the selected piece took almost an hour. |

See video

|

Dr. Picza allows exporting the model in .stl format |

|

Using Rhinoceros, the model is reviewed and the mesh is improved. This allows the printing of the scanned object. |

|

|

|

|

|