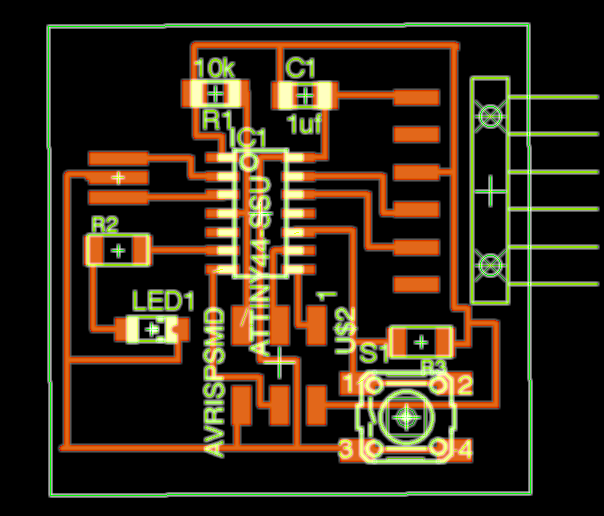

Image of hello echo board in eagle.

Coming from absolutely no background in designing or programming PCBs, this assignment was rather daunting. Fab modules does not work on my computer so I had to use them at the LCCC Fab Lab. I figured out how to use eagle. Eagle's interface is very user friendly and I was shocked and overwhelmed at the vast libraries of components, and commonly known manufacturers. I had always thought this kind of knowledge and ability was eclectic and expensive to acquire. I guess I was wrong in that presumption.

After a few hours of rearranging components in Eagle I was ready to export the board image to fab modules to create a toolpath for the Modela. The board took about 15 minutes to be printed. There were two individual paths: one for the inside components and another for the shape of the board.

I soldered the components with relative ease, although I pulled up the traces around the 2x3 pin on my first board. On my second board I managed to solder everything and the board worked. Unfortunately, my second (and last!) board was broken at the same 2x3 pins area. The traces came up as I was trying to disconnect it from AVR Dude. I was so upset.

Image of hello echo board in eagle.

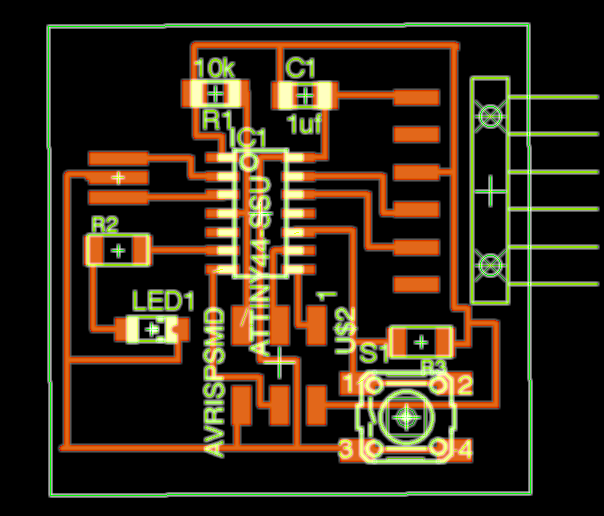

Schematic of the board.

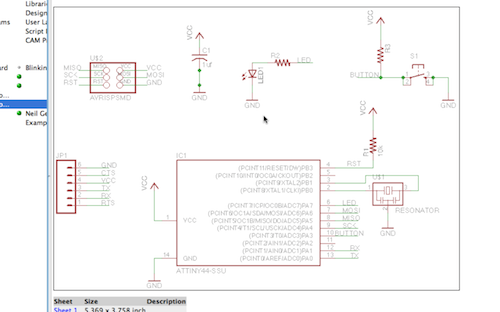

Board being milled on the Modela.

Hello board straight from the printer.