This week’s assignment was to familiarize

ourselves with some computer-aided design programs and use the laser cut machine.

The first is cleaning the lens before cut.

The laser cutter wasn't very difficult to use. I'd recommend trying out your press-fit to get the right dimensions before cutting out the whole job.

Always do a test to observe the appropriate parameters.

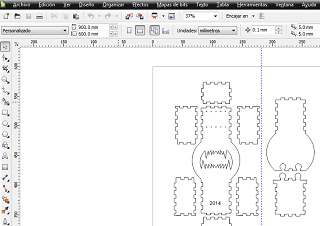

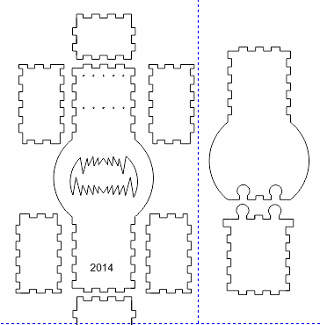

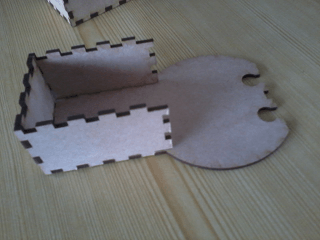

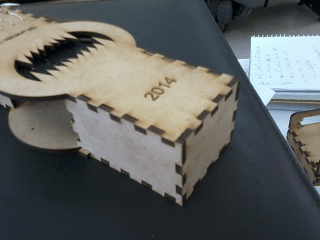

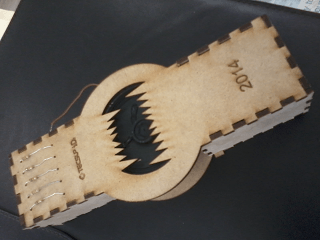

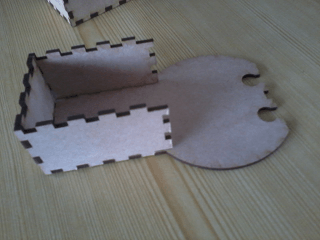

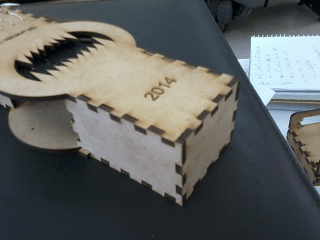

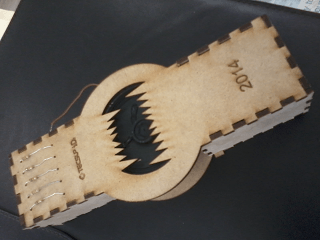

I was design the object in Autocad 2D (in my case)and export them to Corel Draw for positioning and configurating the laser cutting machine according to the material. In my case, I used 3mm MDF.

The designs we see are to work with 7 years old children, I decided to

use this work to learn to use Press-Fit system Autocad.

To use the Epilog Laser Cut, Legend 36EXT.with MDF form material. I practice with Corel Draw the parameters.

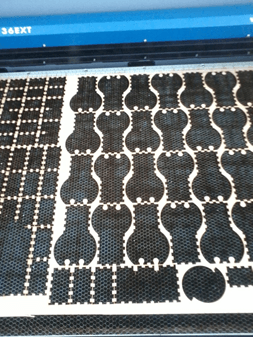

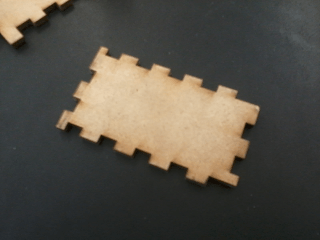

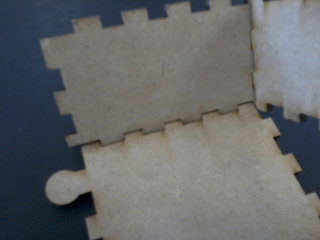

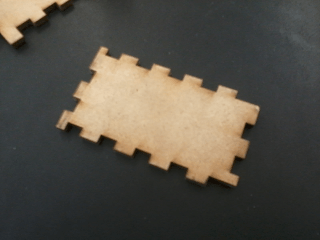

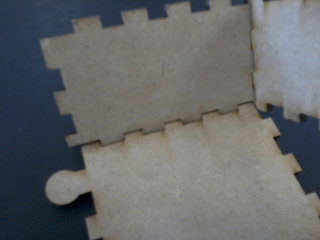

The cutting result is as follows:

I had problems with the material thickness in parts had 2.8mm thick and other 3.1. That provoked in certain parts fit very well while others enter with more difficulty.

Observations:

made with acrylic, I saw a difference between the trim and the outcome measured. Measured is a bit smaller than expected, the acrylic when he was heat with the laser, shrinks a little.Of course the cutting parameters of the machine change.

All files, from this works , are here

The laser cutter wasn't very difficult to use. I'd recommend trying out your press-fit to get the right dimensions before cutting out the whole job.

Always do a test to observe the appropriate parameters.

I was design the object in Autocad 2D (in my case)and export them to Corel Draw for positioning and configurating the laser cutting machine according to the material. In my case, I used 3mm MDF.

To use the Epilog Laser Cut, Legend 36EXT.with MDF form material. I practice with Corel Draw the parameters.

The cutting result is as follows:

Observations:

made with acrylic, I saw a difference between the trim and the outcome measured. Measured is a bit smaller than expected, the acrylic when he was heat with the laser, shrinks a little.Of course the cutting parameters of the machine change.

All files, from this works , are here