This week’s assignment is create a plan and document for final project that integrates the range of units covered:

But an important question is: what is it?

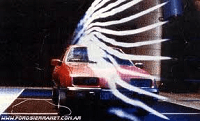

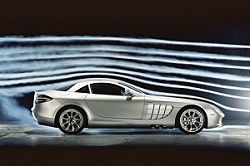

Let's start by defining wind tunnel : It is a tool that allows us to study the behavior of air when we put an object in the flow. That object can be anything: a building, a Formula 1 car, a helmet, a cyclist, and so on.

we must consider that the size of the model will influence the test results. The larger the model and the closer to reality, the better the test results.

This allows us to study the relative motion between the object and the air.

If you search in google: "buy wind tunnel"

you obtain a lot of entreprises who who have done it.

http://www.aerolab.com/media.html

http://usm.maine.edu/east/2012-surf-wind-tunnel-design-and-construction

http://www.vigyan.com/capabilities/wind-tunnel1.shtml

And others.... But, here in Peru,no one has done it, and also can be done at a fraction of the cost using local materials.

They use diferent types of material for each part of the project.

For mechanical structure:

The most important components of the electronics parts are:

I found the plywood, MDF, and Acrylic at a local shop.

About the electronics, most of the devices are available at FabLab, and the others can be found in electronics local shop.

The most expensive part is the mechanical parts.

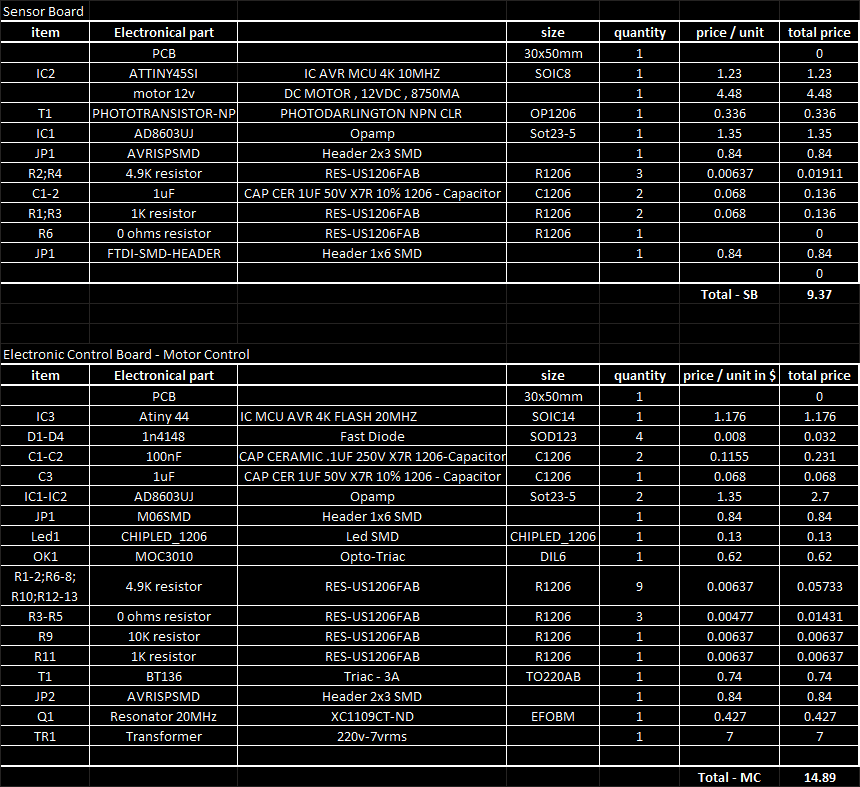

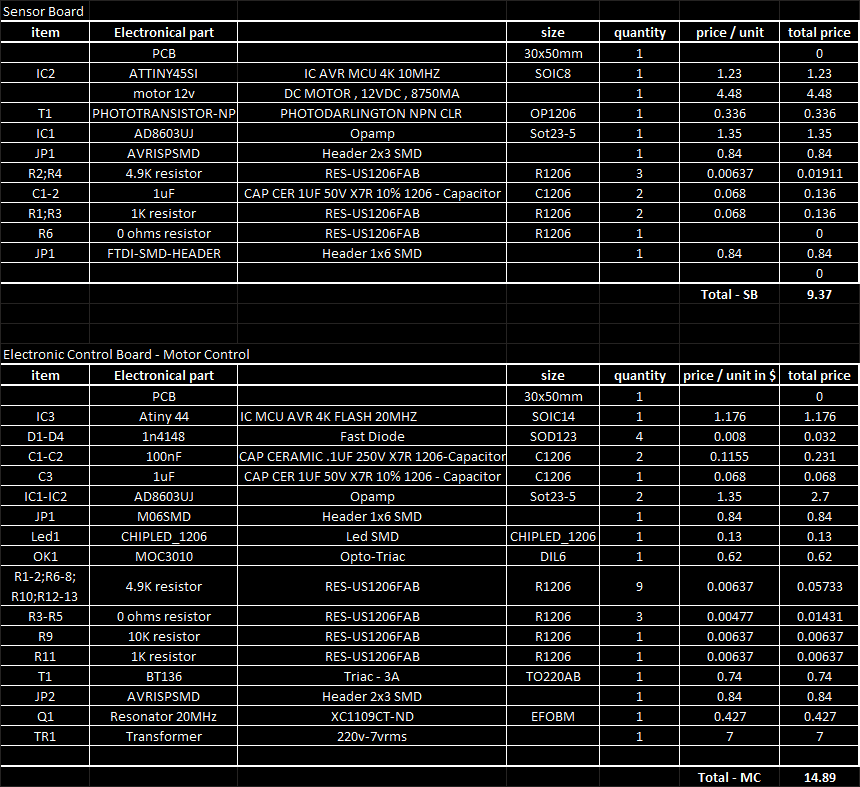

Electronic parts

From the white glue and sereine, to make windproof the hub, it's not easy to evaluate the real cost, because I used a little of each one.

Another cost that is dificult to evaluate is the motor because I use one from a damaged fan.

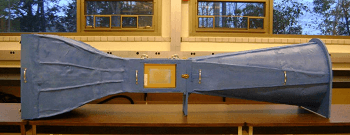

I’m going to make all mechanical parts using the shopbot and making composite material for Hub parts and for the expand parts. They are made of wood.

For the central parts, I will make them using MDF and acrilyc.

The mechanical part of the anemeter is made ( or impress) with the Replicador 2X.

For the electronics Boards (sensor and control), I make all of them in the fablab.

I think putting a toy car in the tunnel to simulate a real car, and look at the smoke movement.

That's all ....

- what will it do ?

- who's done what beforehand ?

- what materials and components will be required ?

- where will they come from ?

- how much will it cost ?

- what parts and systems will be made ?

- what processes will be used ?

- what tasks need to be completed ?

- what questions need to be answered ?

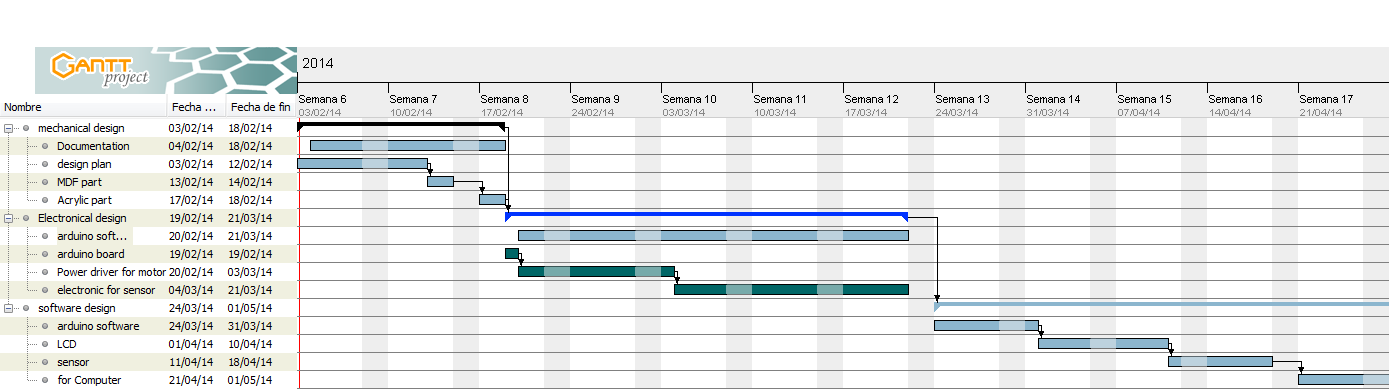

- what is the schedule ?

- how will it be evaluated ?

What will it do ?

My project is to design and manufacture a wind tunnel.But an important question is: what is it?

Let's start by defining wind tunnel : It is a tool that allows us to study the behavior of air when we put an object in the flow. That object can be anything: a building, a Formula 1 car, a helmet, a cyclist, and so on.

we must consider that the size of the model will influence the test results. The larger the model and the closer to reality, the better the test results.

This allows us to study the relative motion between the object and the air.

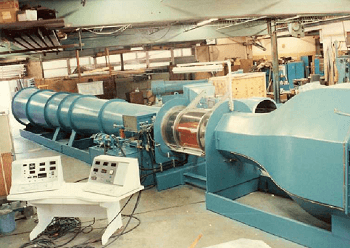

who's done what beforehand ?

If you search in google: "buy wind tunnel"

you obtain a lot of entreprises who who have done it.

http://www.aerolab.com/media.html

http://usm.maine.edu/east/2012-surf-wind-tunnel-design-and-construction

http://www.vigyan.com/capabilities/wind-tunnel1.shtml

And others.... But, here in Peru,no one has done it, and also can be done at a fraction of the cost using local materials.

what materials and components will be required?

They use diferent types of material for each part of the project.

For mechanical structure:

- Plywood

- Acrylic

- MDF

- Material for finishing

The most important components of the electronics parts are:

- Atiny44

- Atiny45

- AD8603UJ (opamp)

- BT136 (Triac)

- Resistors, capacitors ...

Where will they come from ?

I found the plywood, MDF, and Acrylic at a local shop.

About the electronics, most of the devices are available at FabLab, and the others can be found in electronics local shop.

how much will it cost ?

The most expensive part is the mechanical parts.

Electronic parts

From the white glue and sereine, to make windproof the hub, it's not easy to evaluate the real cost, because I used a little of each one.

Another cost that is dificult to evaluate is the motor because I use one from a damaged fan.

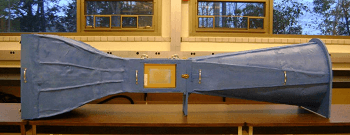

What parts and systems will be made?

I’m going to make all mechanical parts using the shopbot and making composite material for Hub parts and for the expand parts. They are made of wood.

For the central parts, I will make them using MDF and acrilyc.

The mechanical part of the anemeter is made ( or impress) with the Replicador 2X.

For the electronics Boards (sensor and control), I make all of them in the fablab.

What processes will be used ?

For the mechanical parts:- shopbot 2d milling ( to make expansion part)

- Epilog laser (to make test zone)

- cutter

- sanding and finishing

- replicator 2X (to sensor)

- Roland Modela mdx-20 milling

What tasks need to be completed?

- optimize electronic pcb layout

- design test zone

- write application program

- Finish it

What questions need to be answered ?

- How can I choose the motor to obtain the wind in my tunnel?

- Can I finish them on time ?

- How can I calibrate the wind velocity measure?

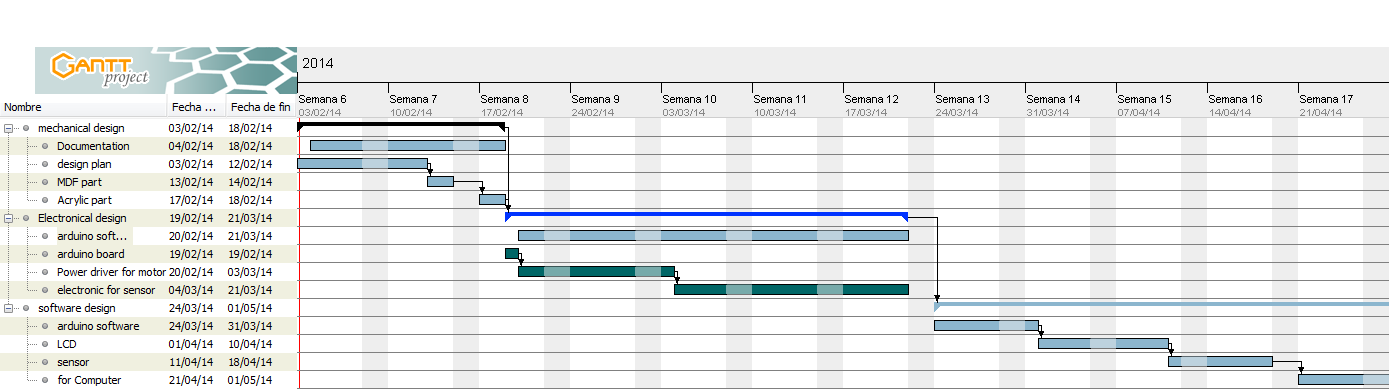

What is the schedule ?

How will it be evaluated ?

How will the wind tunnel be evaluated ? Good question.I think putting a toy car in the tunnel to simulate a real car, and look at the smoke movement.

That's all ....