Week 12 composite materials

by Moritz Begle

Posted on April 16, 2013 at 15:00 PM

Composites

The aim of this class assignment was to create a composite material using a mold/ epoxy raisin and natural fibers. The tuturials and general informations can be found "here"

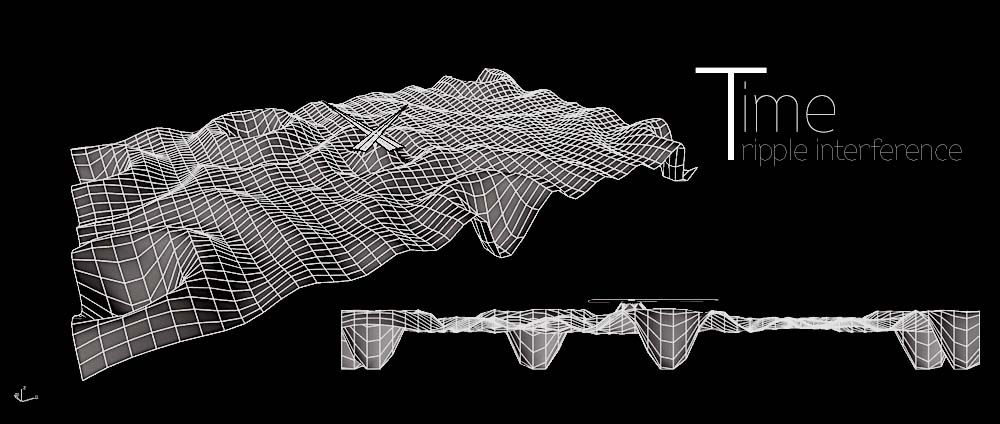

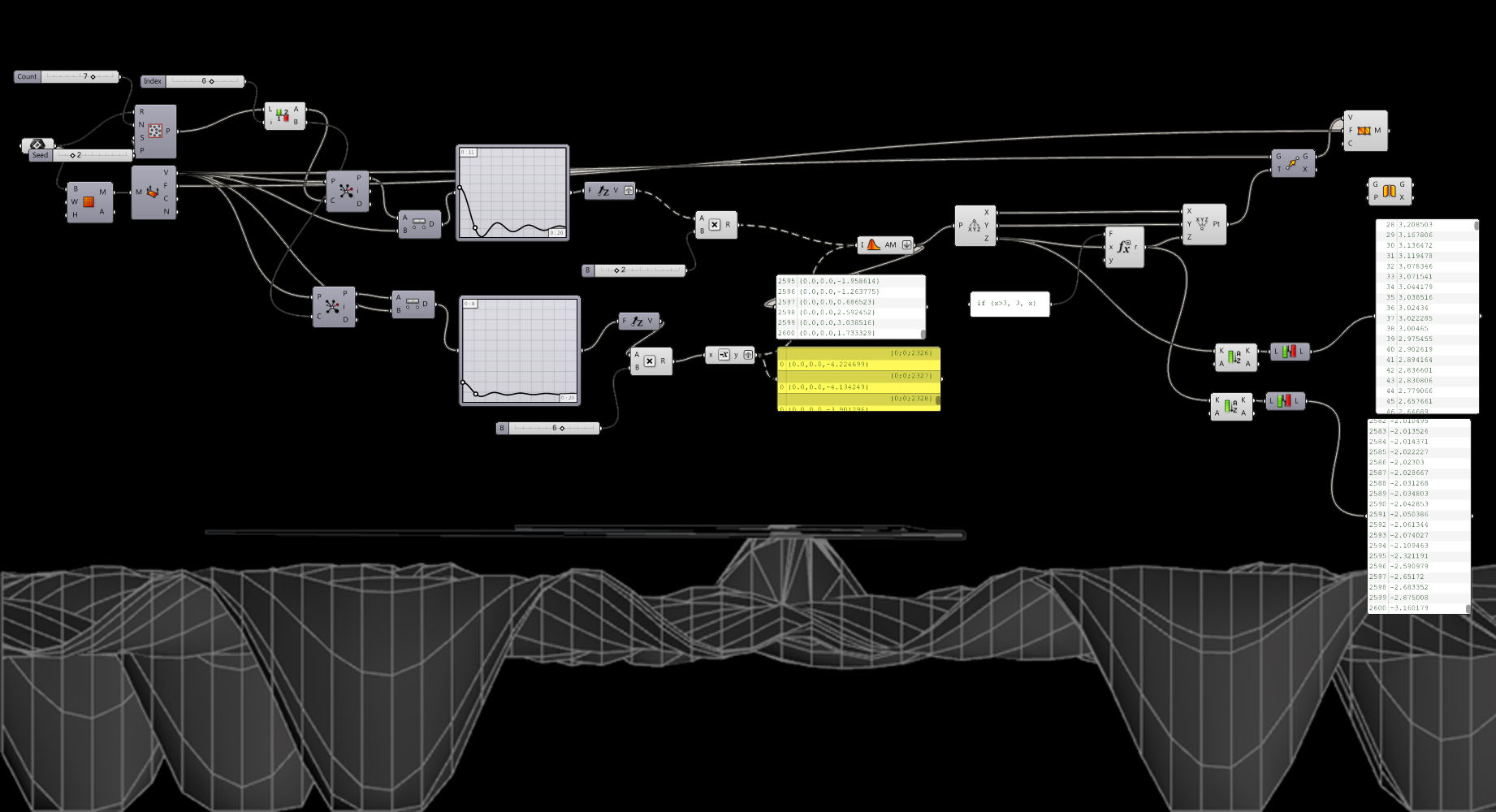

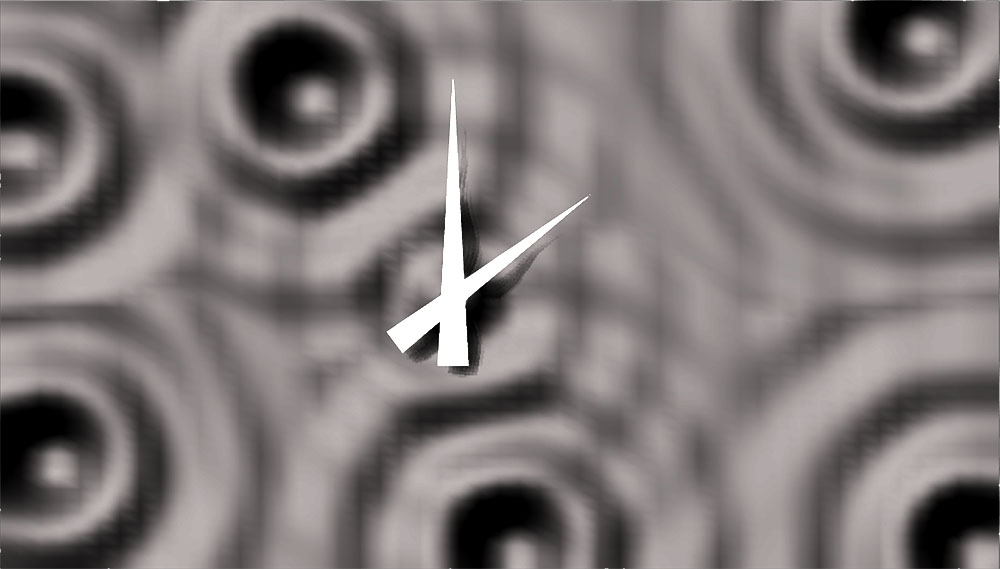

My design proposal is to create a clock. The code involves a grasshopper script based on the skript of David Rutten - Ripple effect which can be found "here"

The skript is creating random points on a subdivided mesh which are then controlled by a graph-mapper to create a water ripple effect.

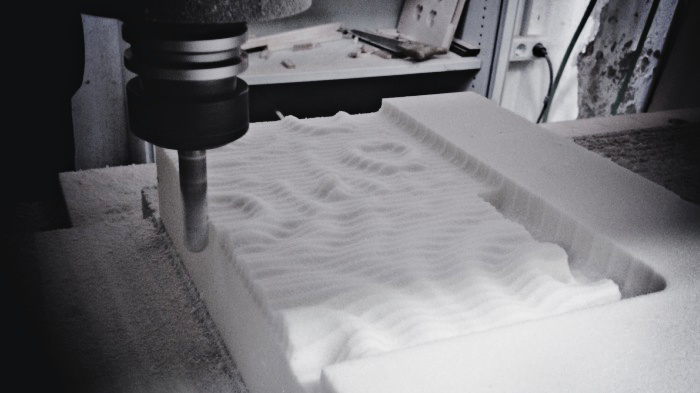

Milling

Milling

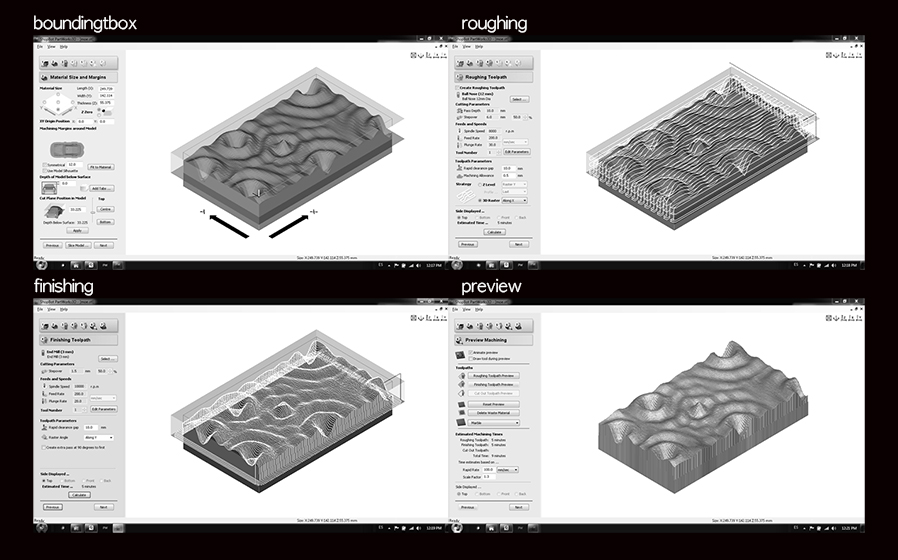

- The final stl design is surrounded by a boundingbox and imported to partworks 3D. 7steps are involved until you get the G-Code which starts from the boundingbox - roughing & finishing - export

For the roughing and finishing simply the steppover from 10 to 1.5 changed, the same 12mm tool stayed.

The overall milling time was only 10 min as we run with a feedrate of 200.

Vacuum Bagging

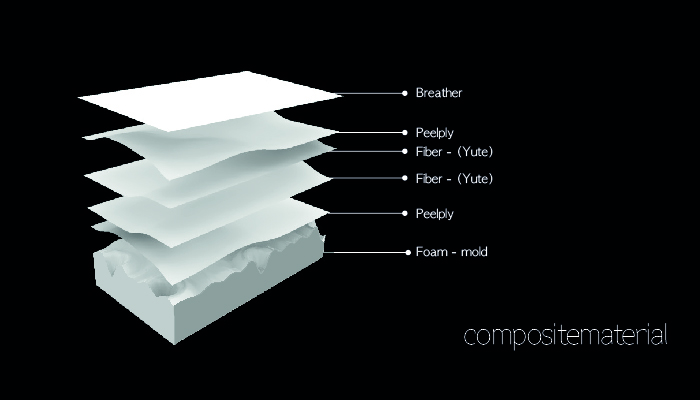

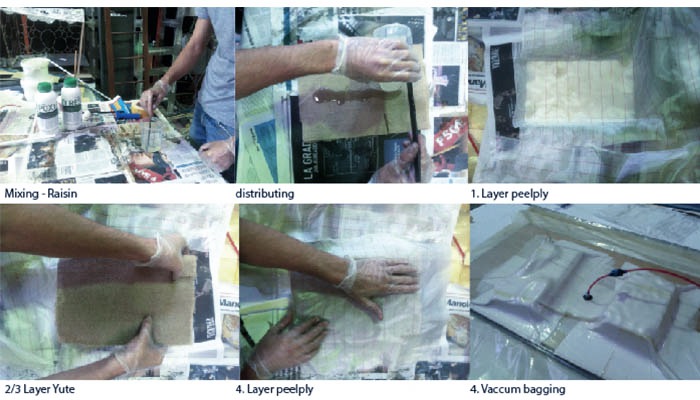

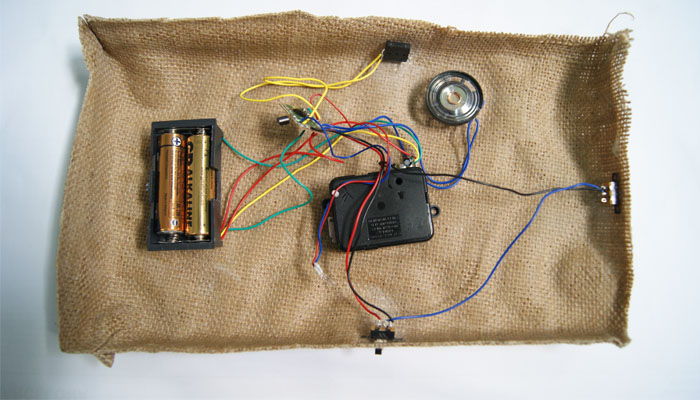

- The composite material consist several diffrent material (top image).

- Mixing ratio 2 parts epoxy, 1 part hardener

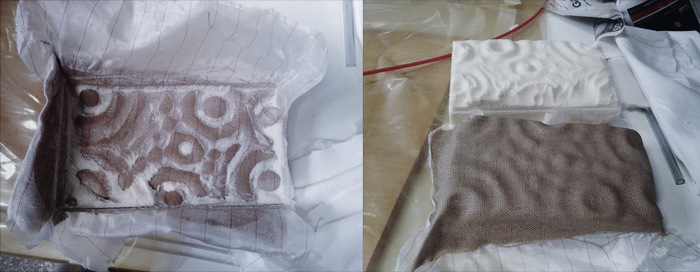

- Vacuum bagging for 6 hours

- I didnt apply any easy release on the mold which caused proplems to take it off from the mold (mold destroyed

Blog Search

Keywords

Web development; blogs; content management; videoconference;remote dektop; project management