This week our goal is to make something big using the Shopbot

I decided to make a pressfit stool. Perhaps not that "big", but it can always be scaled up to make a table and it will give me good practice using the Shopbot.

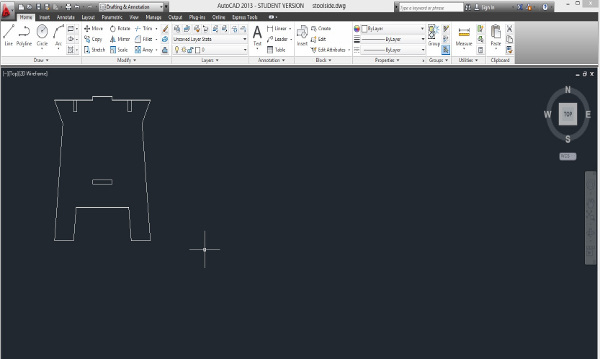

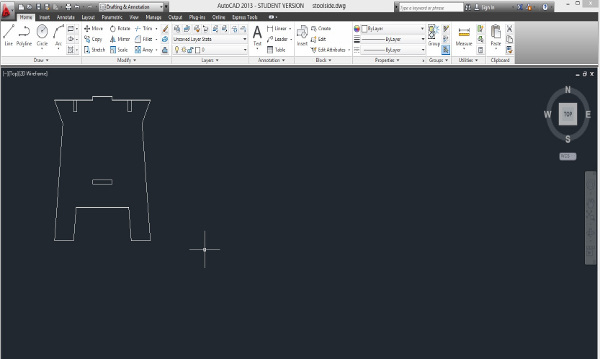

I designed the stool to be a pressfit item with .50" plywood. We had some plywood left over from our last trip for supplies, so I decided to try to make a piece that fit on the half of the sheet that we had left over. I drew the parts in a sketchbook for a while until I had a stool that I thought would work. I then drew the parts in Inventor and then exported them as an older version of DXF that the Shopbot software could understand.

Brad showed me the basics of the Shopbot and helped me load the parts into the program and create the path for the cut. I started the cut above the material, and then stopped the job after a minute or so to begin the real job. After making sure everything was well, I began the cutting process.

After the first pieces were cut, and after a few minutes had passed, it became apparent that the machine would run out of material. It hit the safety cutoff and stopped the job. If I had been more patient and ran the entire job above the material, I would have found this out the first time. Regardless, all was well, I just had to restart the job, this time removing the parts that were already successfully cut. Some of the pieces did not cut all the way through the material, but it was nothing that a little shop knife couldn't fix.

I took the pieces home and made a stool. A bit small, but more sturdy that I would have imagined.

Here are the files if you want to play with it a bit yourself:

back to index