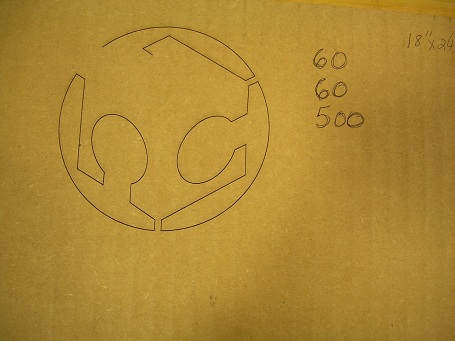

Vinyl signage will be cut to indicate either Kat Kondo or Cat House with the "o"s being turned into profiles of mice.

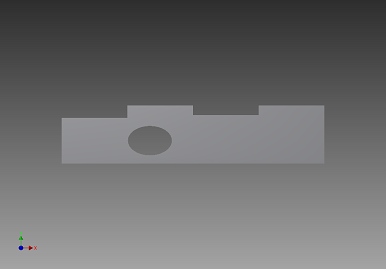

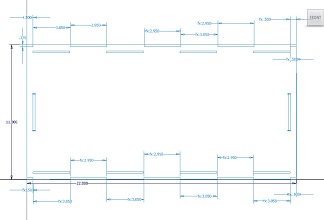

After having tried a number of different drawing tools I have decided to revert to Inventor. I am able to do parametric modeling in the program. I still intend to explore other programs but will do this after I get the laser cutting process and tolerance issues mastered.

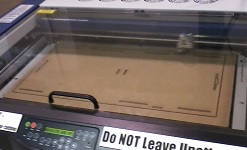

At last I have a usable drawing suitable for the laser engraver. It took some time to figure out that I needed to draw a 3D model in Inventor, turn to a front view and export a 2D view. I ended up setting the background color in Inventor to white and choosing a solid black model. When the object is turned to view the front only the resulting image can be exported in a file format that the laser cutter will read. This is particularly important since the laser cutter is one of the busiest pieces of equipment in the lab. I will need to be off and on the laser cutter in a timely manner to be courteous of others.

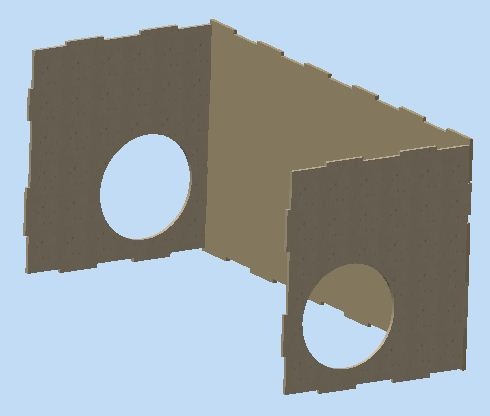

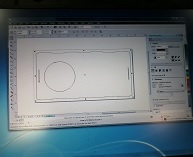

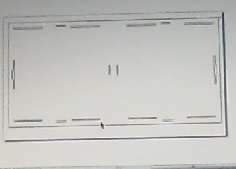

I was able to import my drawings

into CorelDraw and create the

necessary paths for laser cutting top/bottom, side, and end parts

with and without holes. I cut enough parts for four "kondo" units.

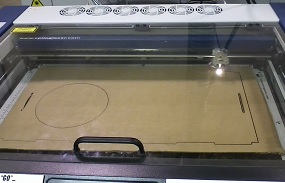

I experimented with the settings to get a cut that went through the cardboard without leaving too big of a kerf. More experimentation with materials over time will help me get a feel for viable settings. I used 35, 90, 500 on these cuts. I think the earlier settings of 60, 60, 500 may have been better.

I used Inkscape to draw the vinyl cut logo to be used on the modules. It gave me experience using a different program and may work well with the fab modules.

The first completed unit is a success! The module was tested immediately after assembly.

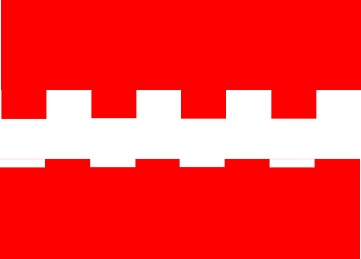

The final setup is a 3-unit "Kitty Kondo". Note that the unit is held together with press fit cardboard locking tabs. I milled some of these with the grain of the cardboard and some of them perpendicular to the grain of the cardboard. Each orientation has it advantages and disadvantages. The tabs cut with the grain of the cardboard are bent easier into a locking position but also bend easier on insertion. The tabs cut perpendicular to the grain insert easier but it is harder to get the cardboard tab to bend. In the end I used the tabs that were cut perpendicular to the grain of the cardboard. In addition to meeting requirements for vinyl cutting, the Kitty Kondo logo ads a bit of spice to otherwise boring cardboard.