Computer Controlled Machining

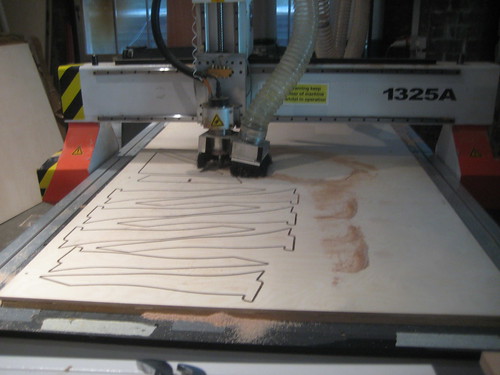

Following on from the cutting layouts that generated previously, I routed out numerous parts for the set for Yarla and the Winter Wood - namely the bases and branches for 11no. 2.4m trees. The trunks of the trees were made from cardboard tubes, the sort that carpets are rolled around for delivery.

I imported the layouts in .dxf format into VCarve Pro. In this I generated cutting paths for the large router table that I would be using. I used my own 1/4" router bit, and used the speed settings recommended by the lab. From this I exported a .nc file of Gcode.

At the router table, we made sure it was swept clean, and screwed a 12mm ply sheet to the sacrificial sheet below. This router table has a vacuum bed, which keeps the sacrificial sheet down, but one still needs to secure the cutting sheet on top of this as the vacuum does not extend above the sheet! For each cutting layout I took care to measure of the layout and mark on the sheet safe zones for screwing near to each corner, so that the router head would not risk hitting any screws.

On the first attempt at cutting we quickly broke my router bit. it turns out that the bit I had was longer (25mm) than that which the setting we used were for (about 15mm), hence the feedrate was too fast for it. I switched to the shorter length bit, used the override function in the control software to cut at 70% speed, and had no further problems.

When importing Gcode from VCarve into our cutting software, we must delete the first two lines. Other than that, the software is very straightforward, and I made used of the simulation playback, to check that the job was setup correctly before commencing. In all I cut a lot of parts for the trees out of 3no. 12mm birch ply sheets in about 3 hours.

The slot together construction worked surprisingly well, with 12.1mm slots, creating a good snug fit. All the parts required a quick sanding on both sides to remove skelfs.

I found that a good way to separate the routed pieces from theirs tabs onto the board was using wome wire snips.

The finished tree bases in rehearsals.

I imported the layouts in .dxf format into VCarve Pro. In this I generated cutting paths for the large router table that I would be using. I used my own 1/4" router bit, and used the speed settings recommended by the lab. From this I exported a .nc file of Gcode.

At the router table, we made sure it was swept clean, and screwed a 12mm ply sheet to the sacrificial sheet below. This router table has a vacuum bed, which keeps the sacrificial sheet down, but one still needs to secure the cutting sheet on top of this as the vacuum does not extend above the sheet! For each cutting layout I took care to measure of the layout and mark on the sheet safe zones for screwing near to each corner, so that the router head would not risk hitting any screws.

On the first attempt at cutting we quickly broke my router bit. it turns out that the bit I had was longer (25mm) than that which the setting we used were for (about 15mm), hence the feedrate was too fast for it. I switched to the shorter length bit, used the override function in the control software to cut at 70% speed, and had no further problems.

When importing Gcode from VCarve into our cutting software, we must delete the first two lines. Other than that, the software is very straightforward, and I made used of the simulation playback, to check that the job was setup correctly before commencing. In all I cut a lot of parts for the trees out of 3no. 12mm birch ply sheets in about 3 hours.

The slot together construction worked surprisingly well, with 12.1mm slots, creating a good snug fit. All the parts required a quick sanding on both sides to remove skelfs.

I found that a good way to separate the routed pieces from theirs tabs onto the board was using wome wire snips.