Assignment : Make something big

--Here article is What I did of this assignment--

Design

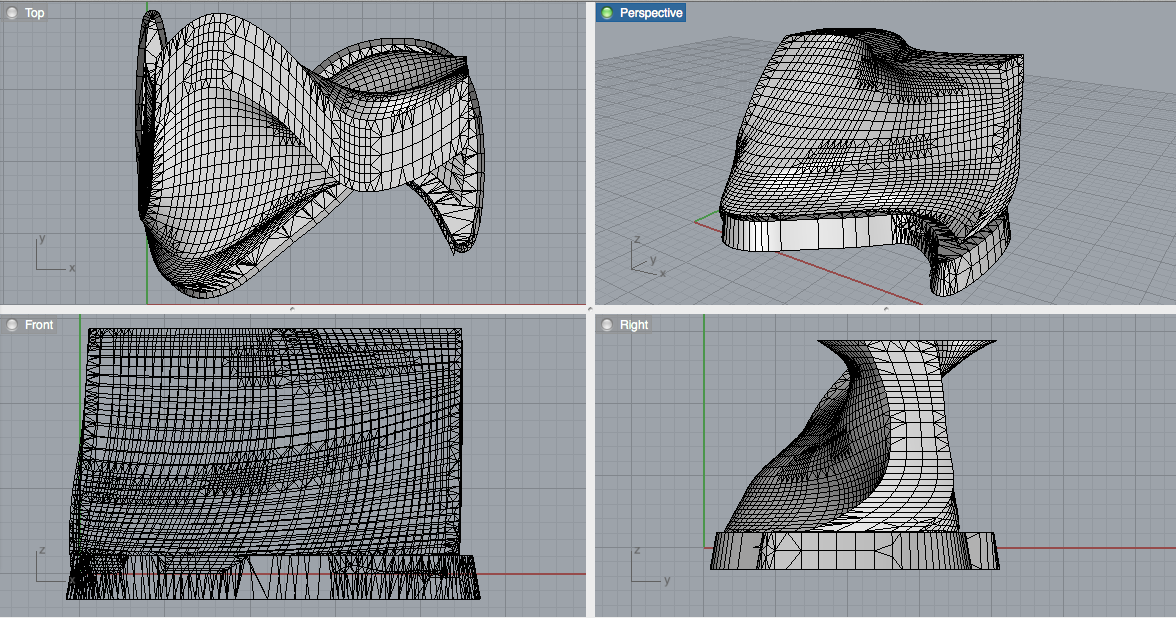

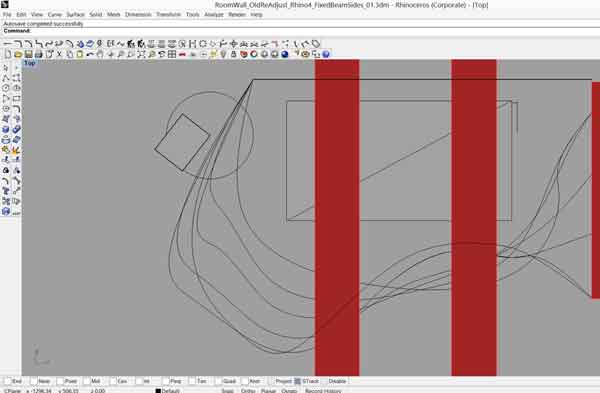

At the beginning, I designed a test structure of wall using the Rhino.

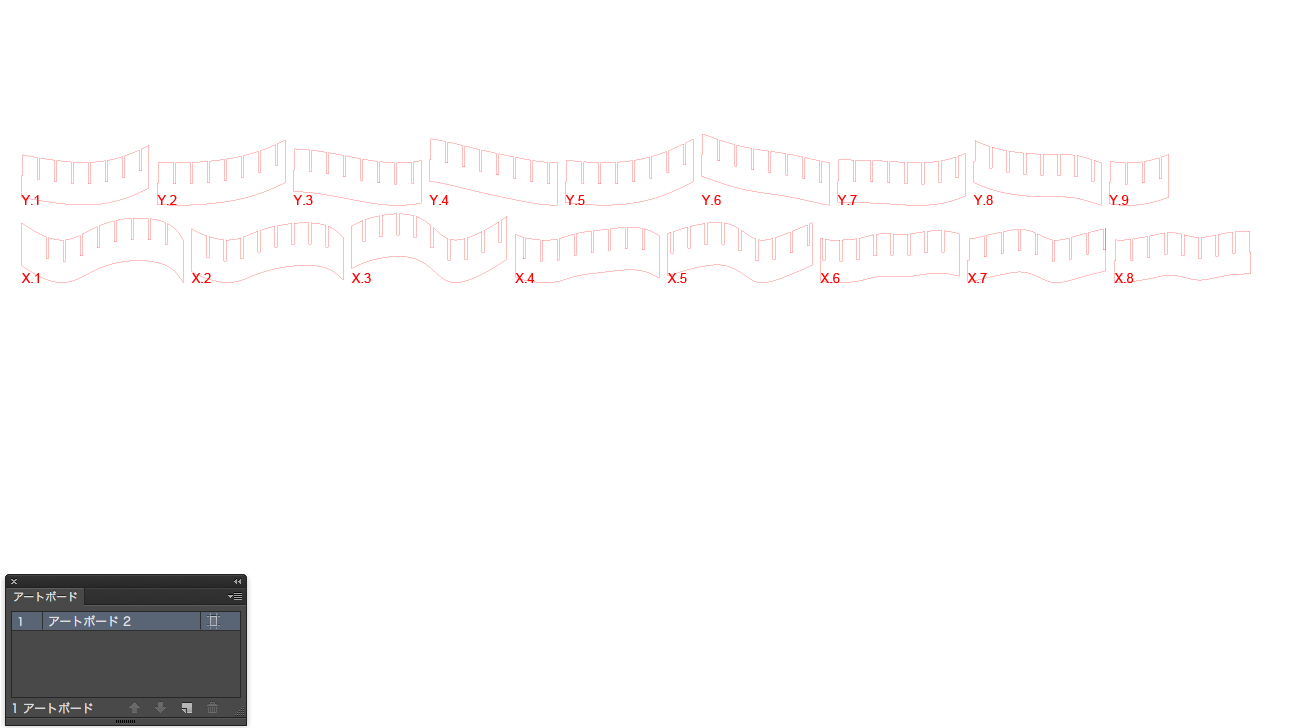

Then I cut design of structure using Python plugin.

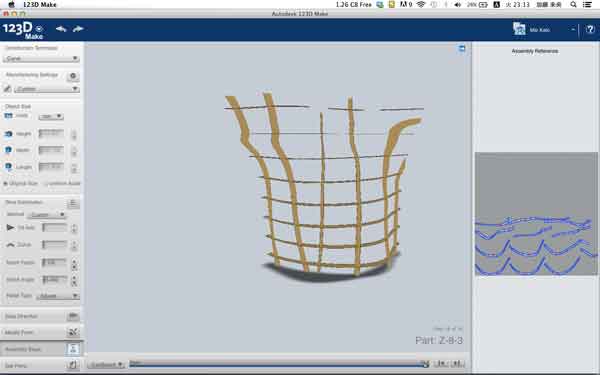

But finally We used a software which is the 123DMake for cutting object.

>> Download here -- Script of cut structure by Python(for Rhinoceros) --

>> Download here -- Script of unroll parts by Python(for Rhinoceros) --

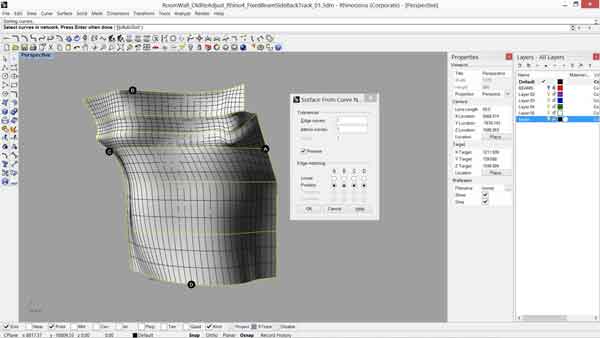

I also studied how to design using the glasshopper, and tried to design.

We didn't use this design, but I learned skill of it.

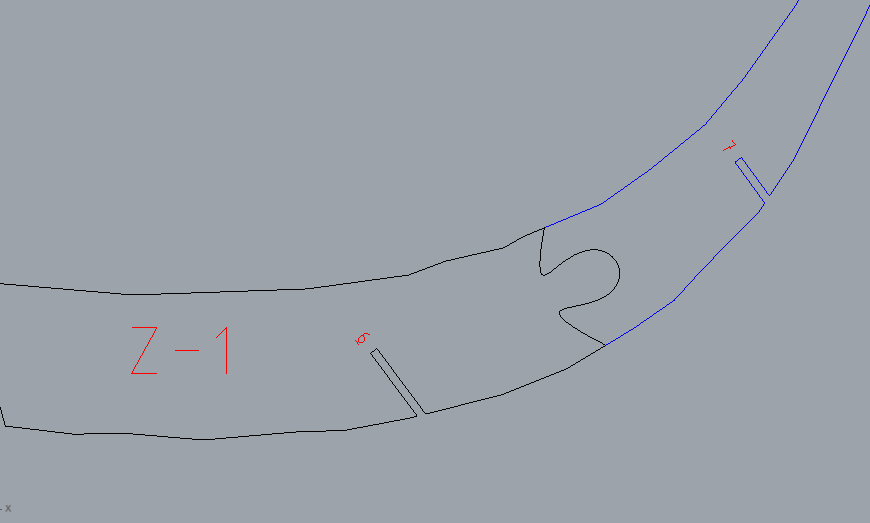

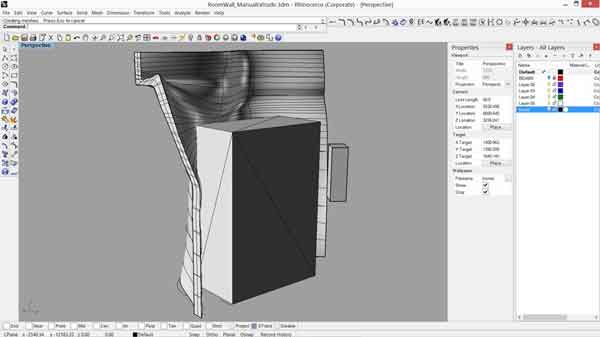

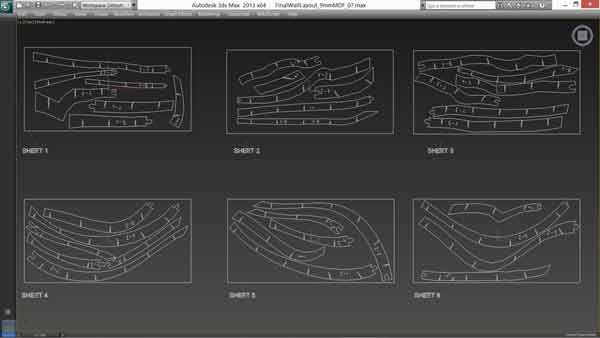

We had to separate parts, because our object was so big.

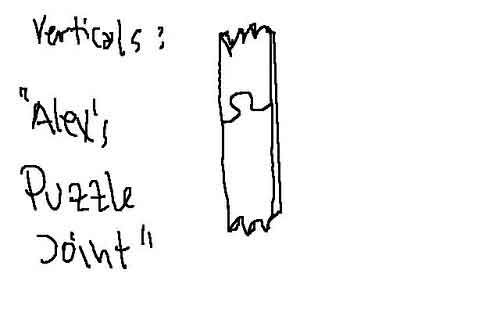

So I designed the cutting form of object looks like Puzzle.

This idea was thought by Alex who is our manager, and I designed using the Rhino and the Illustrator.

--Below article is made by all of us--

This week assignment is making something big.

Amsterdam student would make a wall which cover a dust correction box of the Shopbot by everyone.

Using Machinery : Shopbot

Using software :

- Rhinoceros

- 123D Make

- Autodesk 3ds max

Lay out a plan making a wall

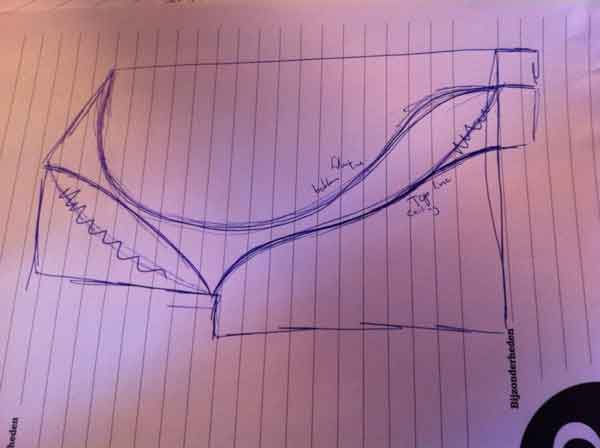

We discussed what kind of design do we make as writing sketches.

We decided to make a latticed pattern structure look like waffle.

I'd like to make beautiful structure along the dust correction box.

Measure a size of place where locate the wall

As we would make a wall correctly,so we had to measure precisely.

Below photo is the place locate the wall.

Design

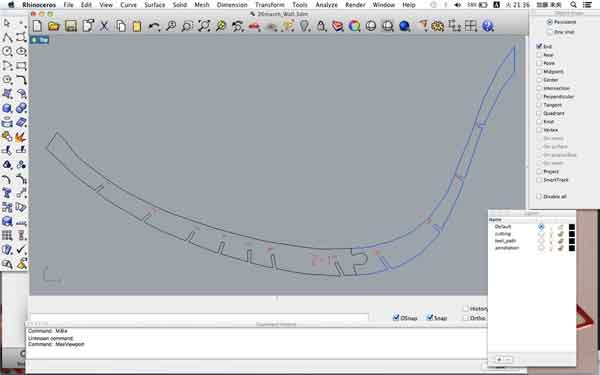

We drew a model using Rhino.

We inputed the dust correction size data and around the wall data.

And We drew the wall along the dust correction box.

We had to cut some connecting points, so we used the 123D Make.

So we exported stl file from the Rhino.

And we imported stl file using the 123D Make and cut the solid, then exported dxf file.

The Shopbot width is 2440mm, height is 1220.

But The wall I'd like to make is 3000mm height.

So we have to separate two parts.

We asked Alex who is our lab's master, he suggested puzzle joint.

We decided to cut center of the parts looks like pazzle.

Cut a board using the Shopbot

Before we make a finished product, We made a small model.

This is card board prototype.

This is MDF prototype.

We exported stl file from Rhino.

We lined some objects using the 3dx max.

These are MDF board which use complied product.

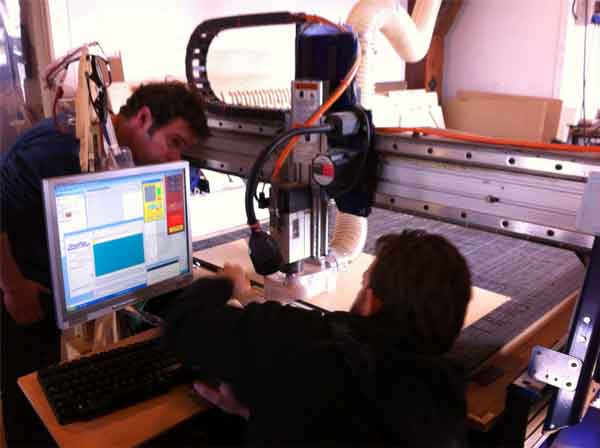

Set up the Shopbot.

Cutting the MDF.

Assemble MDF boards

We had a problem.

As material sickness was correct, These material did not fit each crevices.

So we had to sharpen them with a file.

I thought we should try to fit, before cut final product.