CLOCK

As mentioned before

in the concept

page, that I consider time as an

illusion, I's the only constant in our life where it

organizes everything yet it's not tangible it's

more of a perception than a physical quantity

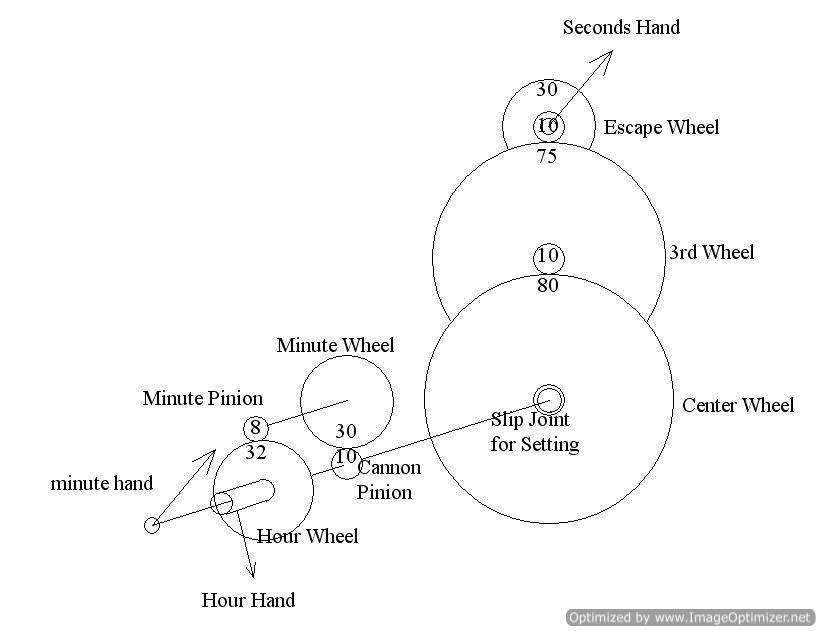

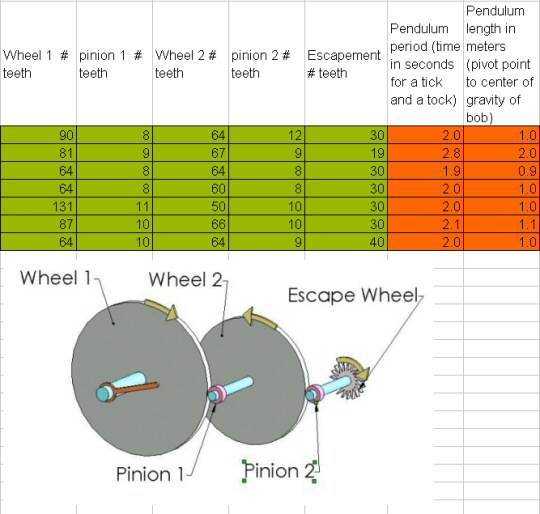

So I started to look

closely at the mechanism of the clock

and how does it interprets time through

mechanical motion.

Whenever you mention clocks, you

defiantly think of gears and thatís

where I started

I was so inspired by DAVID C.

ROY wooden kinetic sculptures while mainly

the whole mechanism is self-initiated

that last for hours some of them last forever.

Shimmer

was the STAR to me the flow of both layers was

exactly what I had in mind

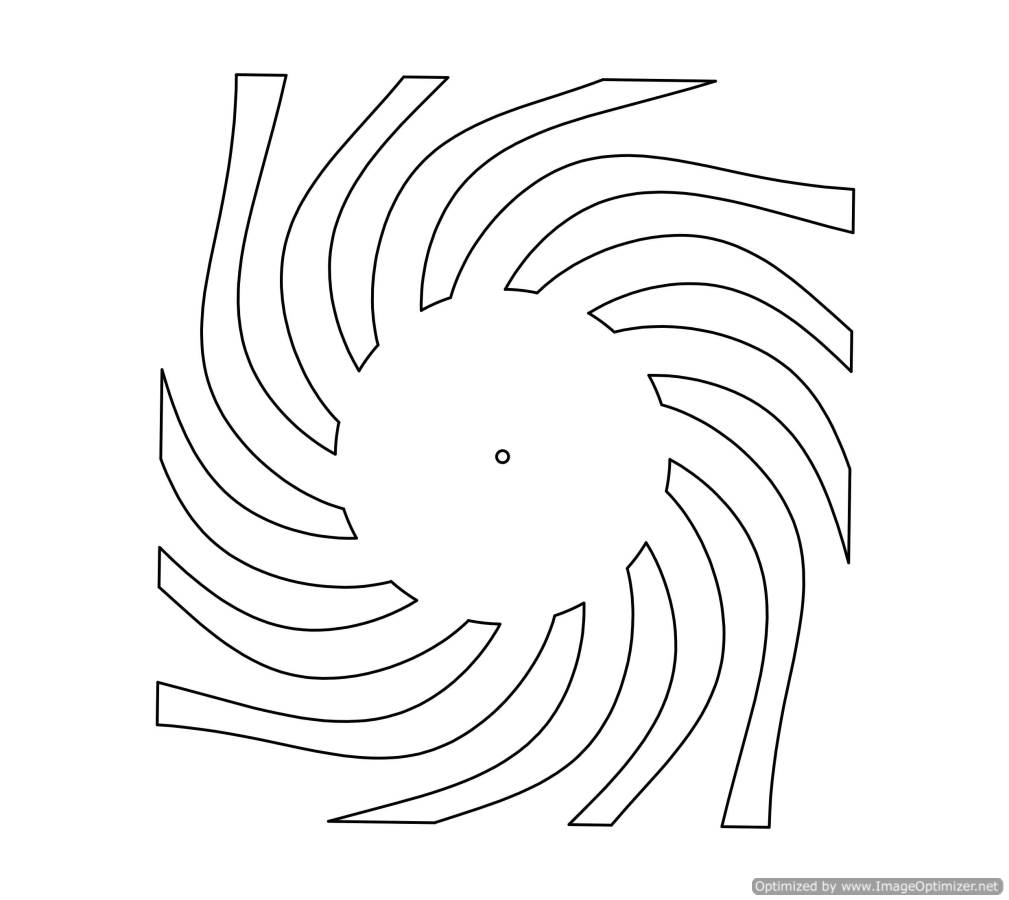

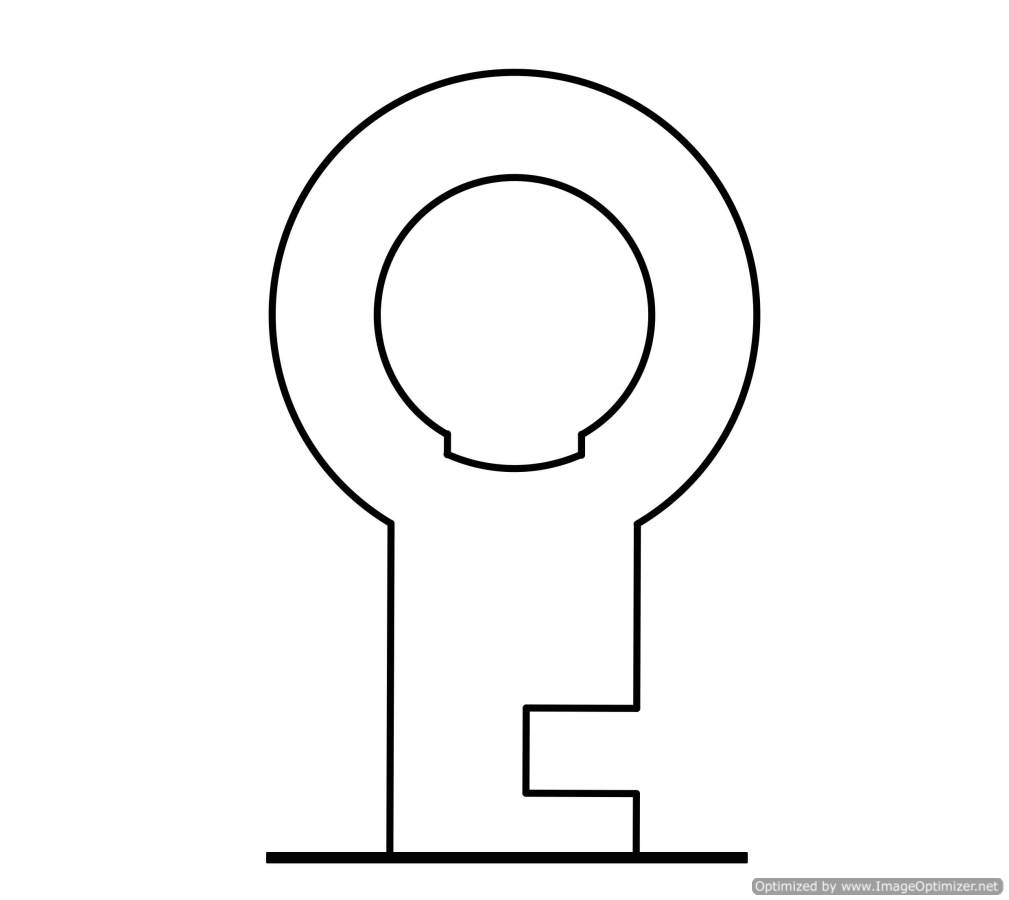

BLIND description for the project

There will be

three layers two with inverted geometrical patterns

while the middle one will tell the clock

so after 6o consecutive revolution of giving a

different layout every minute it will move the layer

behind it (the one that describes the clock in

numbers)

Then the back one with the

inverted geometry will be the one connected to

the proximity sensor, it will sense when someone

is looking at it and revolve

in the opposite direction of the front one

giving a different effect (similar to the

shimmer effect)

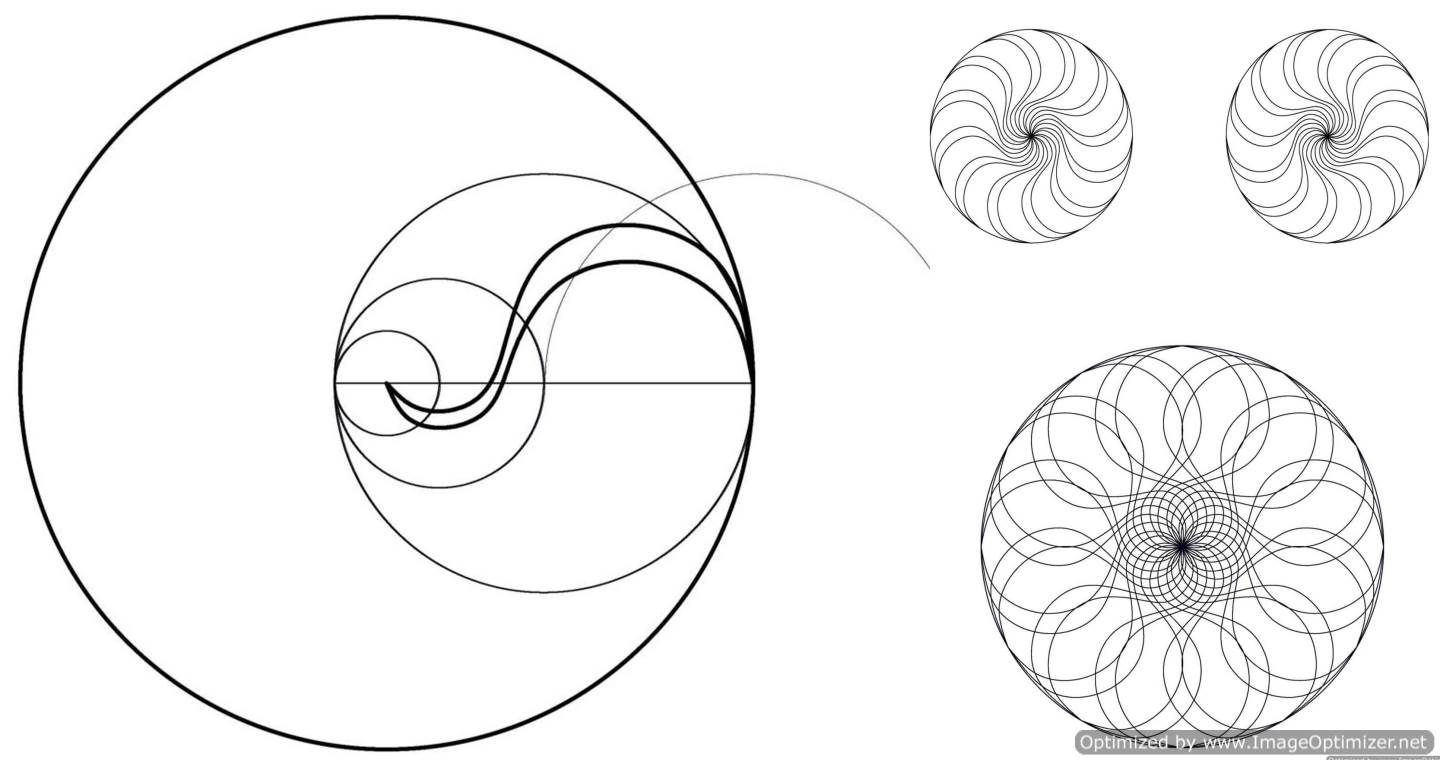

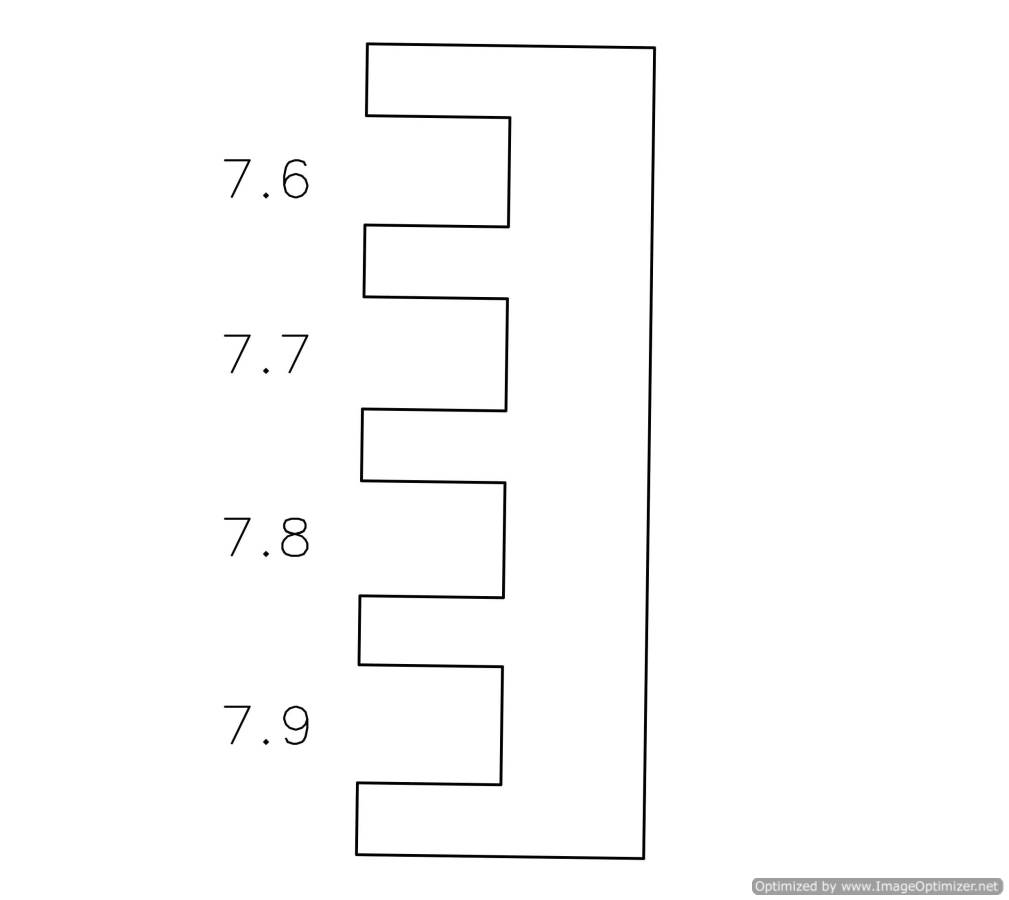

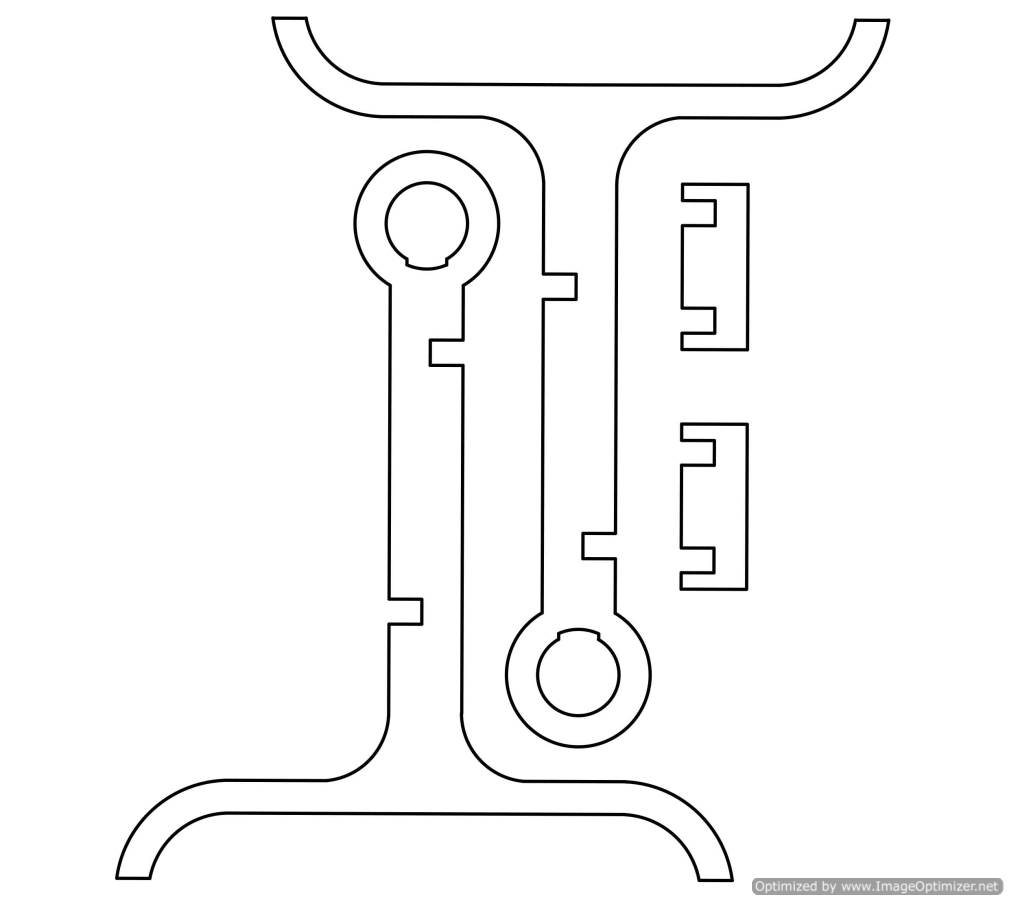

i started by designing the

two gears for the visual effect, i used AUTOCAD

2013 for the 2D form generation

FABRICATION

please not that

some documentation were lost that's

why I'm referring to some failed

trials with diagrams instead of real

pictures

I

started using bamboo for both the gears and the

carrying arms where the two gears will revolve on. i

started by testing the hole where the motor will fit

in,

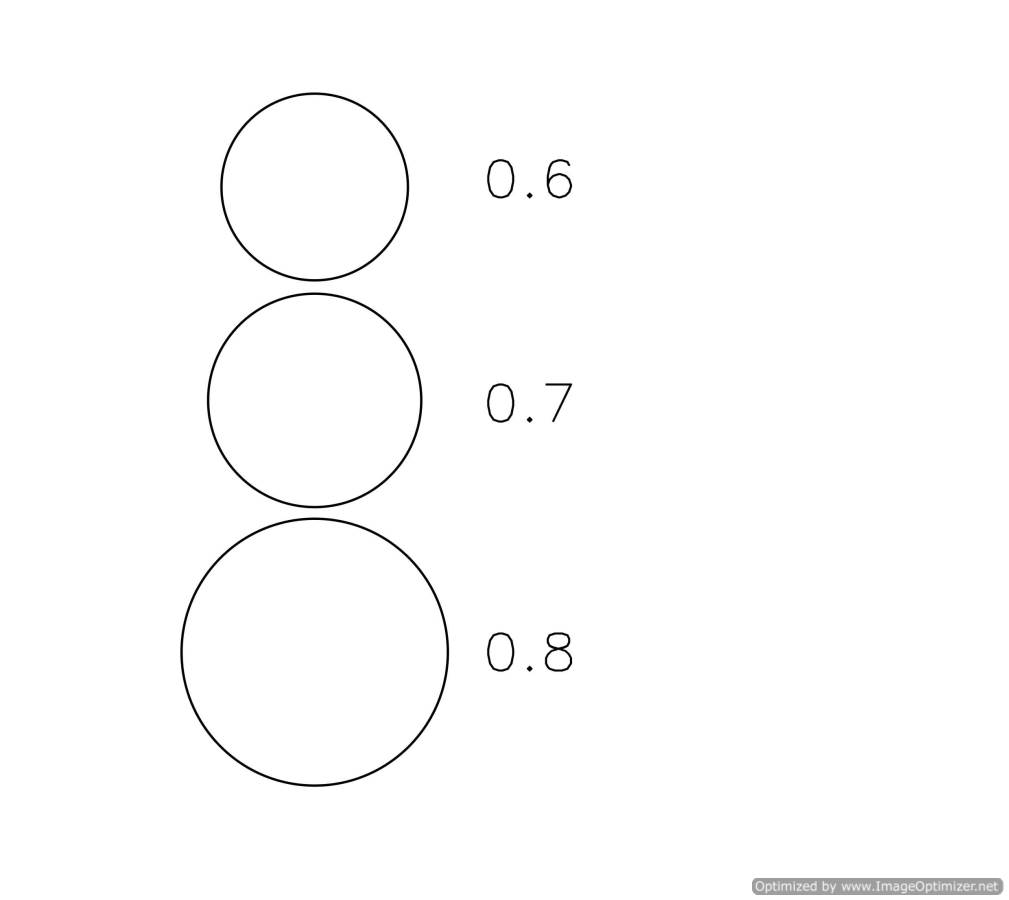

i used three different sizes, examined them on a

small model of the gear, i used the 0.7 as the 0.6

broke while pressing it and the 0.8 was

too loose the gear didn't spin with the motor

.

I used the big laser cutter with speed 16 and

power 80 as the thickness of the bamboo sheet

was 5.2mm

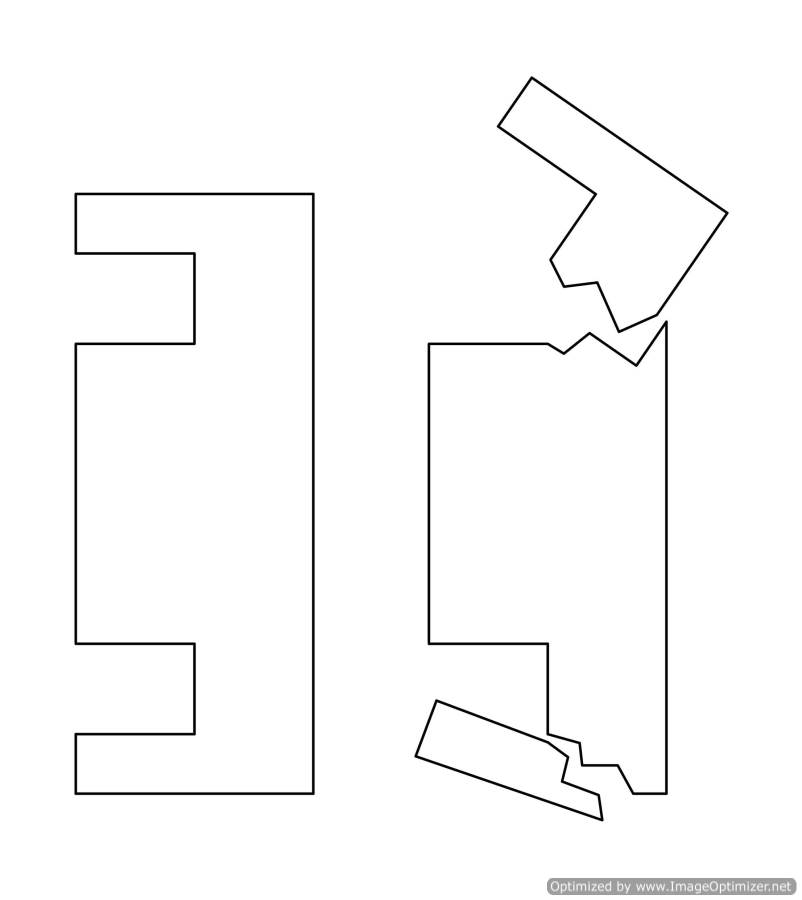

amboo

is a natural fiber that has a direction you cant

use it with thin sections specially if it was

press fit, B

the rapid use, the fibers gets easily

disconnected i tried overcoming that by

changing the section of the arms, they ended up

too wide for the use!

in addition to this they both were too thin

to stabilize

watch

the video

To solve the

problem i had to use a thicker material, i used MDF

wood with thickness 8mm, the thickness helped the

model to stabilize even while

moving the motors and gears. it was better to use the

milling machine with this material but it was busy and

i had no time so i used the same laser cutter

I kept testing the speed and power till it cut through

with speed 8 and power 60 i had

to modify the bed of the motor to fit exactly

the size and allow

the cables to pass behind the supporters.

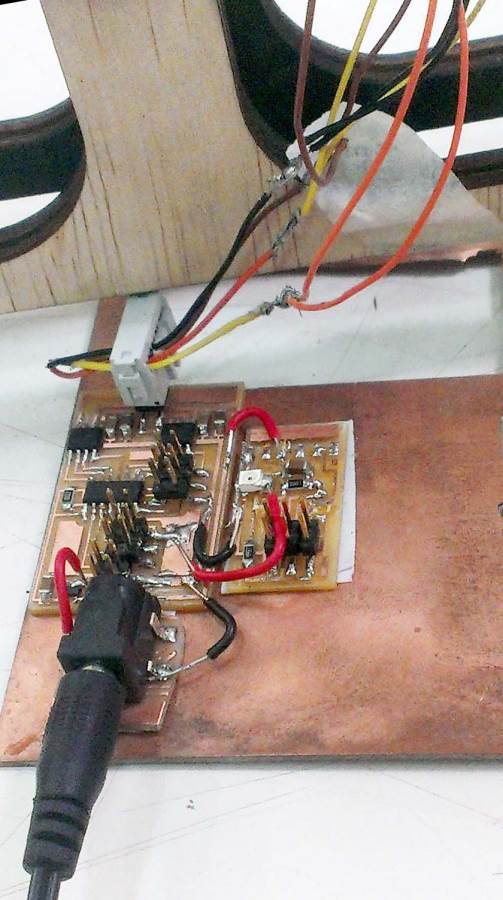

ELECTRONICS

at the I didnít want to use the ready

proximity sensor I wanted to design my own one,

with references I managed to make the infrared one

that

worked with a transmitter and a receiver LEDs with

the metal isolator between them. the sensor worked

and it was reading but the results were

poor in difference, I wasted

sometime trying to develop it but then i

ended up using my light sensor ready board

from the input

devices week

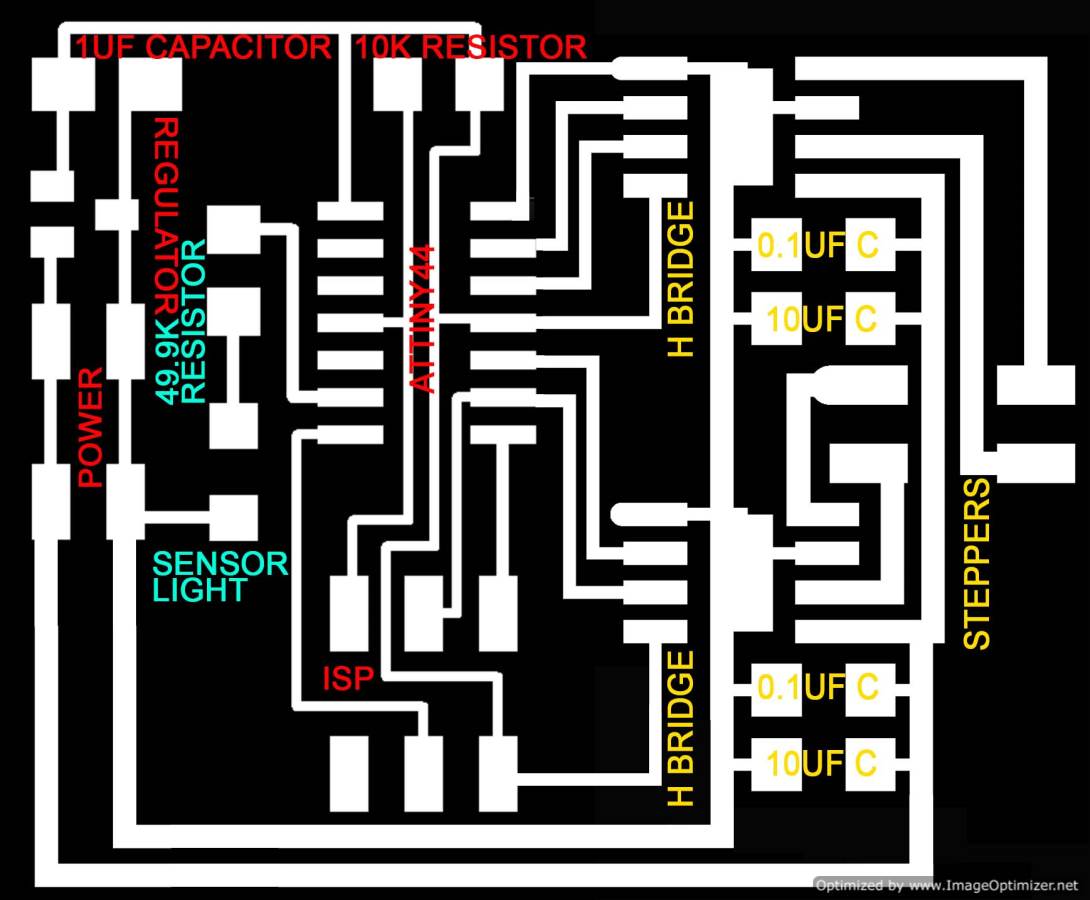

The board was simply designed to input the values

from the sensor and translate them to control the

motor's speed

Choosing the components?

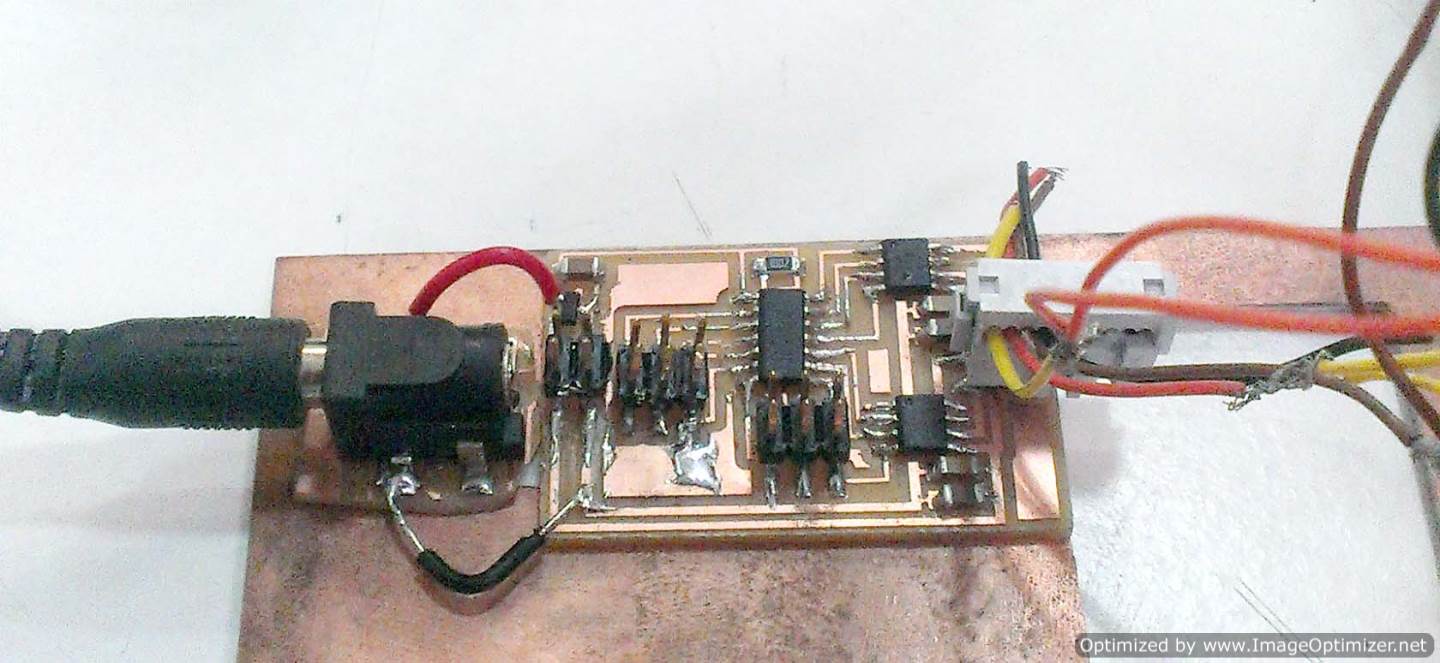

please

note that during the first final round i

didn't have time to design the board on

eagle so i used the ready ones i've

already made from the past

weeks,i added jumpers and they worked

fine, later on after the first submission

i had time to design the board with the

same components on one board

The micro controller: ATTINY44 was the choice

as for the number of pins and the memory it has is

suitable to store the program and run it efficiently

The

light sensor: it needs

a resistance along with it so I used the

49.9k. It also needs to be connected to a reading

pin in the microcontroller so I used PA7

The

steppers: I used

unipolar steppers but by excluding two wires I was

able to use them as bipolar as they proved through

research that they have more torque

with high speed The idea with the motors was to turn

both motors from the same board, so I arranged the

coil cables identically so that when they are

placed back to back they spin

in the different direction (watch

the video)

Power supply: in order

to turn both motors at the same time I needed a

voltage higher than 9v so that when I added the

power jack. The power jack has

direction,

the one I used had a metal bar from the side that

indicates the positive input

The

regulator: along with the power supply came the 5v

regulator to regulate the current coming from the

power jack and fix it to maximum 5v

Capacitor:

it's advised to use a capacitor before the

regulator in the power line to keep it cool and

avoid burning it with high current

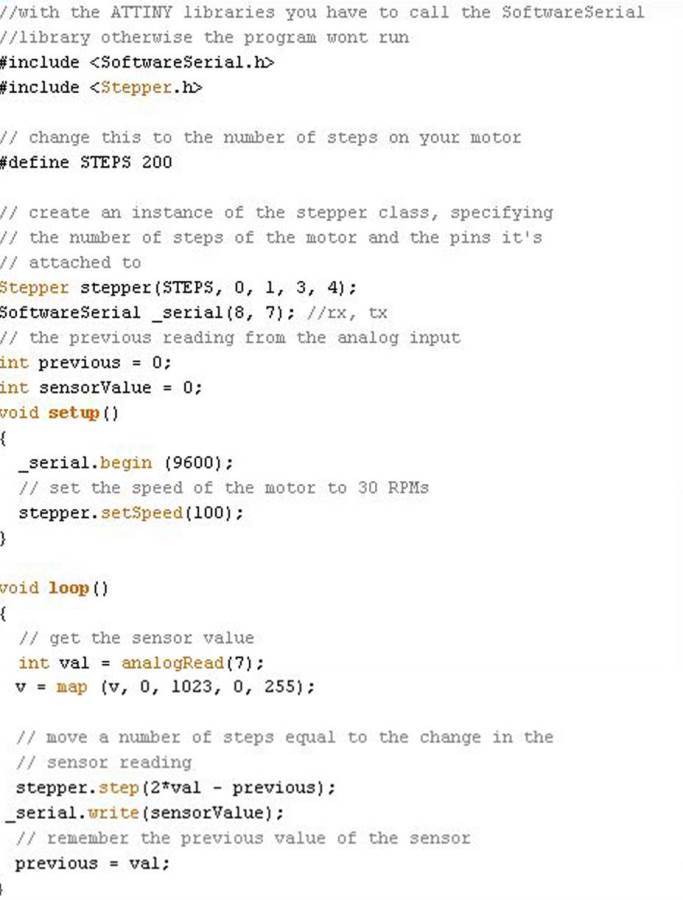

i used Arduino to program this microcontroller, i modified the stepper code, to read input from the light sensor added at it

at the beginning the sensor value were so wide for the motor to read, so i mapped them with a math equation then they worked fine

watch

video one

watch

video two

IN THE END!

I didn't

come up with an invention that changed the world

but in fact i did change my life, 6 months ago I

knew nothing

about clearly EVERYTHING, so I'm grateful to

every one, my gurus, my class mates, and even to

Barcelona for this life time experience

FROM CAIRO

>About

>Proposal

>Digital model

>Laser Cutting

>Electronic

production

>3D Scanning

& Printing

>Electronic Design

>Molding & Casting

>Embedded programing

>Computer-controlled

machining

>Input devices

>Composites