As part of the group project my task was to design and make the stepper motor mechanism taht would control the height of the two stages that would go either up (left hand resovoir) or down (right hand)

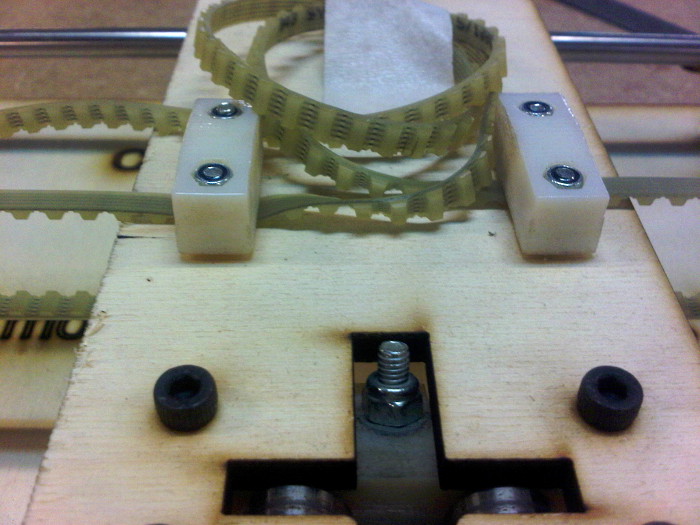

The structure was designed to use a single stepper and some parts recycled from an old RpRap 3D printer; including the sliders, bearing runners, slider mounting blocks and the stepper output gear.

This design was lazer cut and mounted on a test mounting board. A number of test iterations were required in order for the notches to work as required in the 6mm (~5.7mm) plywood.