Computer Controlled Cutting

In this assignment I decided to test different materials joints, use cardboard and acrylic to be cut on a laser machine.Process

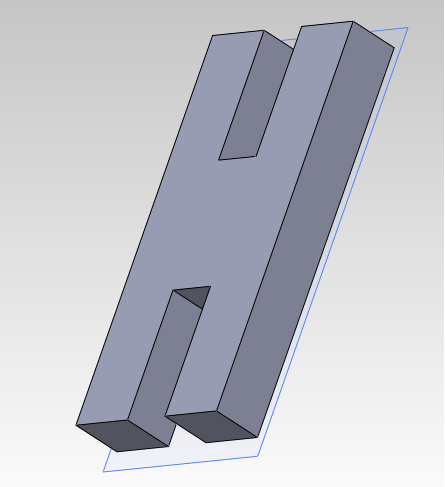

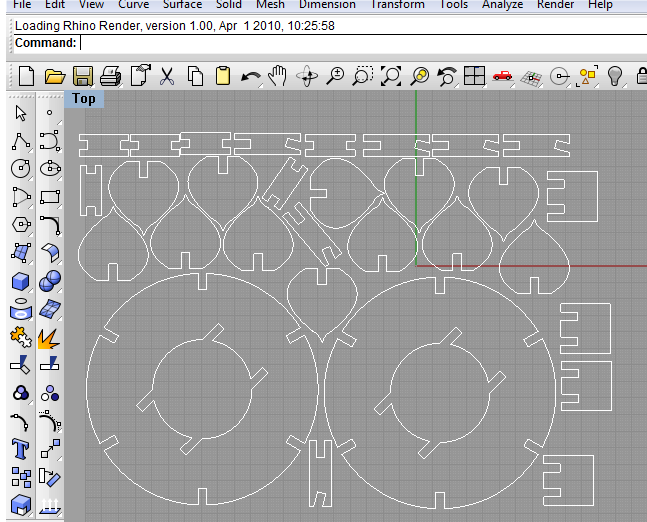

Maybe it is a dual process, but it served to see the assembly, the design and assembly in solidworks, then export a file format DXF, in order to be cut Rhino, send the DXF to CorelDraw for printing on the laser machine, that's the whole process.

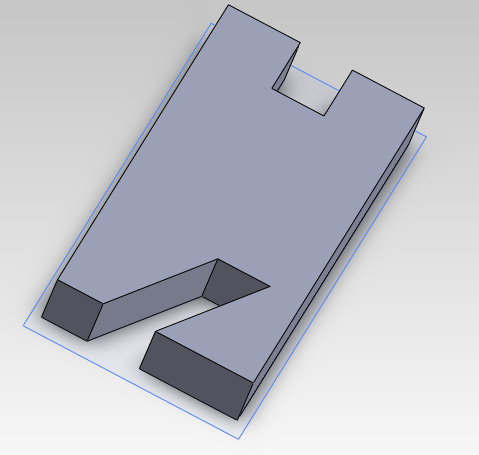

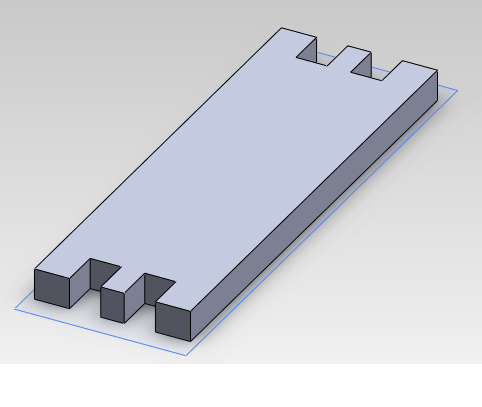

Tests on cardboard Work carton of 4 mm thick, and these were the designs.

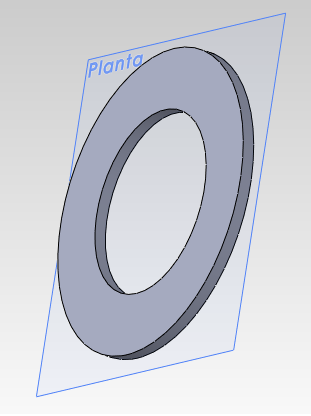

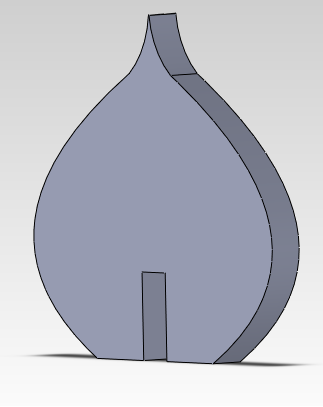

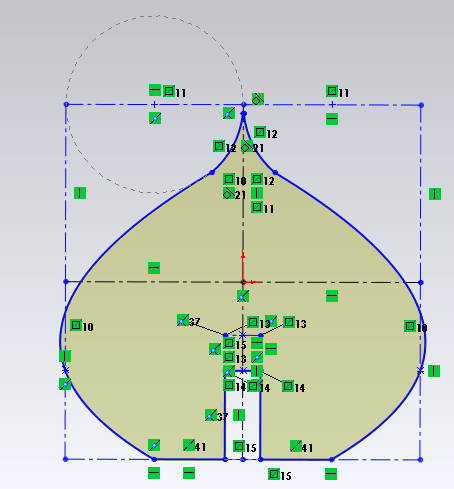

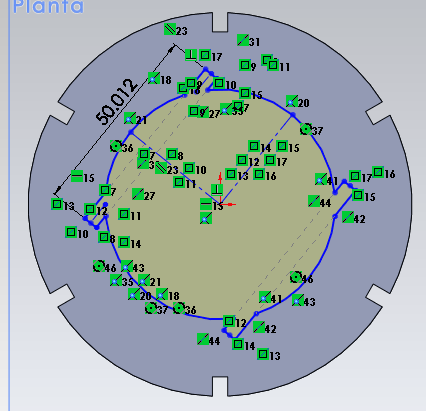

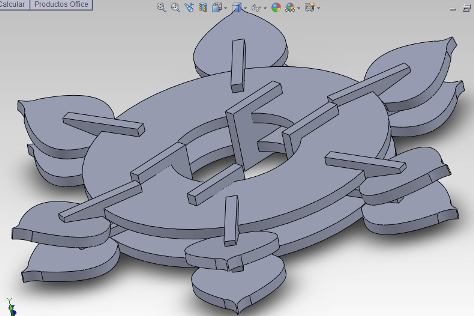

The circle radius is 50mm and an inside circle of 30mm,to make room for unions of petals, space in the inner circle is to fit another piece.The petal design it by defining the space with an area of auxiliary lines 20x20mm, using curved lines and a circle of radius 10 mm, watch

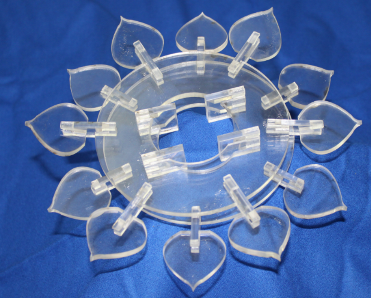

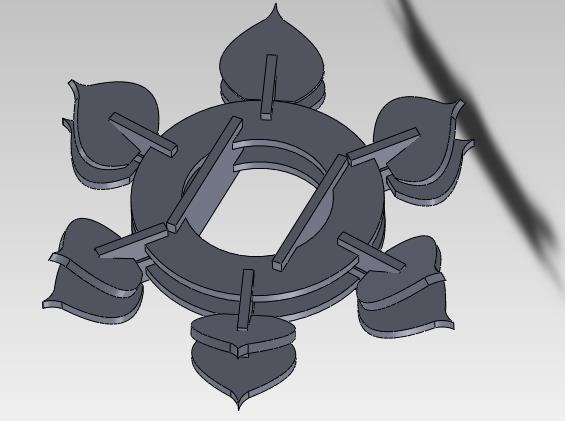

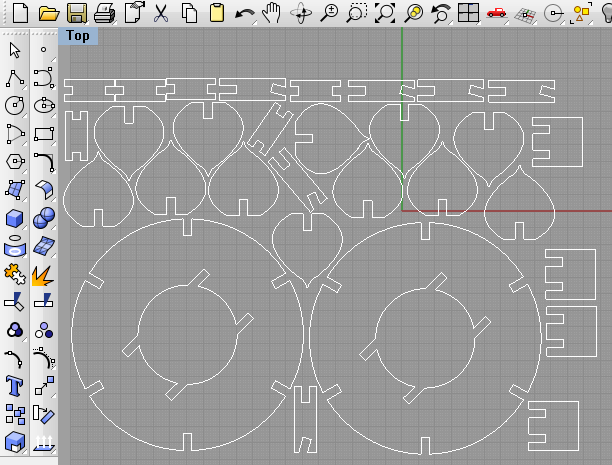

Then ordered in Rhino (watch left image) and the final result of the design is as follows:

Joints in carton should consider a less than 0.2mm thickness material, because the board is burned and the space between the joints are broad and could be loose. Another observation is on the central junction, as the flexible board, worked, but in other rigid material would have been a failure.

Tests on Acrylic

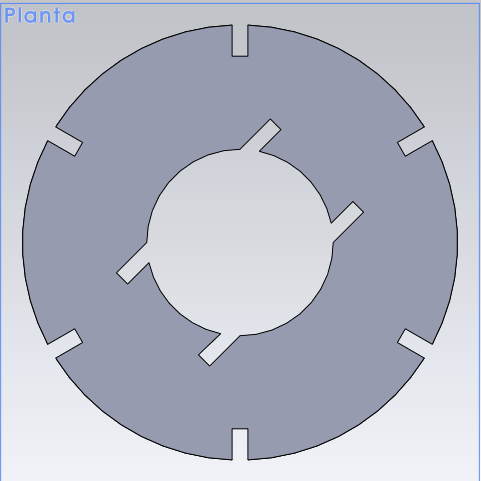

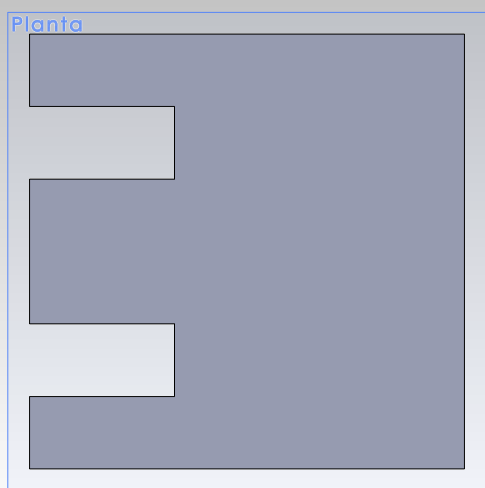

Modify the central junction for assembly acrylic, Expand the radius of the circle to 70mm, and the inner radius was maintained, the unions to 5.1mm, New designs being so:

Then ordered in Rhino (DXF) and the final result is as follows:

Is left at junctions 1 mm more, if your thickness is 5mm then the unions should be 5.1mm, behavior is different from the cardboard