What will it do?

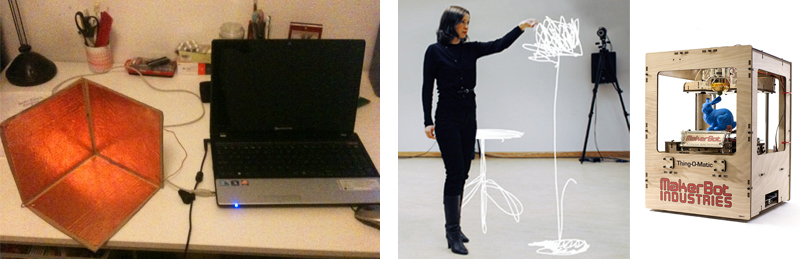

My final draft is to make an interface 3d capable of capturing the movements of the hand and/or stylus,

in order to draw the object in space directly in three dimensions. So that it draws a line in space as you go

by defining the path of your movements. Finally, this line could be exported to a file '.stl' to be printed in

a 3D printer directly.

What materials and components will be required?

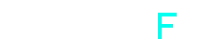

For the initial design I used cardboard for the structure and 3 sheets of copper as capacitive sensors (as indicated on the website of Kyle).

But for the final design I would use a little more durable materials such as plywood for the structure and fabric as a capacitance.

I would also need an insulating material on the back of the structure to focus capacitive sensors towards the center of the box, such as neoprene.

Concerning the hardware, each capacitive sensor is attached to an input pin, which in turn is attached to a 10k resistor,

then have another 1M resistor and the capacitance between the 5V power supply.

I cannot make a list of the final material because I think what I use will depend on the final size of the object.

If I draw on my experience, what I have used so far will be enough, but I think in the end I will have to adapt the components depending on the received signal.

Who's done what beforehand?

Based on Kyle McDonald's project called 'DIY 3D controler' I would update the design to make it a little bigger,

portable and more robust. And implement it with the capacity to save the data of your movements.

The overall dimensions of the object would be about 50x50x50cm, perhaps 1m. But this depends on the type of material to

use and the interferences in the signal that this will spark.

What parts and systems will be made?

I will try to make as much I can. Theoretically the technology used does not require a very advanced hardware.

I will try to make a specified board with ATtiny 44, an ISP connection, and a FDTI to receive the data to the computer,

apart from the other components necessary for proper operation..

What processes will be used?

Structure: laser cut, milling machine.

Board design: milling machine, soldering and programming.

Software: programming in processing.

Printing of object: 3d printer, makerbot.

What tasks need to be completed?

I need make a real-size prototype of the object to see what answers have the capacitances, and how they affect the interference.

Modify the Ardunio code to make it slightly faster.

Modify Processing software to store data path drawn, and can be exported to. Stl..

What questions need to be answered?

I would like to know what material I can use to isolate my hand to the effects of capacitance or to have a

little more resolution in the drawing. My intention is to draw with a stylus or something similar.

Referneces

DIY 3d controler

3D Laser-Sculpted Furniture

Flemming Tvede Hansen