Home >Cyclonic Filtering

It is alway preferred to vent the air from the filter outside!

As venting outside is the very best way to cope with the ultra fine dust milling mdf and other woods creates.

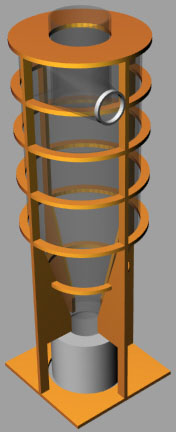

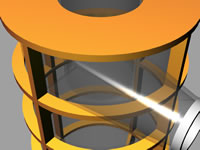

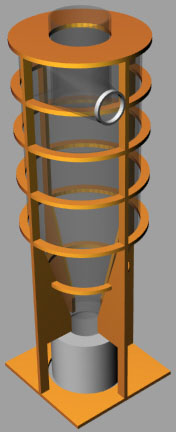

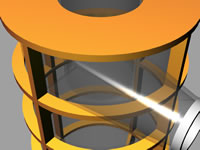

Build a cyclonic filter for our shopbot.

Animation will be added after i get mencoder under control :P

Animation can be downloaded here.

The dimentions of the cone are key to the success of the filter.

Actually, the whole thing could be is a parametric design.

Normally you would start by determining what you actually need (in terms of material removal). From that you'd determine the necessery CFM (Cubic Feet per Minute). On that you'd then base your duct-sizing, size of the cyclone, horsepower on the motor etc.

At our Fablab we have most things in place already. We did refit our current fan with a bigger motor, because our previous motor burned out and we could get this at a discounted price. Also a Speed Regulator had been added. Ducting and duct sizes are fixed already to it's going to be a matter of using those fixed values to calculate the sizes for the cyclone.

Importance of fan-blades (why changing them could make sense after adding the cyclone): Efficient Fan Blades (pdf)

Per suggestion of Neil i'm going to (try to) design the whole thing following Bill Pentz guides. I'm also going to include a fan blade design which we could make in the fablab.

As we need to get all of the fine dust we need about 1000 CFM airflow just to meet EPA and medical air quality standards.we also need to get the hood of our chopbot changed (3d printed design anyone?). As the skirt needs to 'just' touch the surface of our workpiece when the router is on the surface, we need to lift the current skirt by about 3 cm. (which is actually highe rthan it can now go) Also we need to change the ducting to the shopbot to 6" diameter.

http://www.mecp.com/downloads/Dust%20Collection_Chris%20Yato.pdf

http://aerosol.ees.ufl.edu/cyclone/section06.html

http://www.clearvuecyclones.com/cv-max/31-cv-max-three-phase-with-filters.html

PET-G @Quinn Plastics

glue for PET-G (epoxy)