Home >Class Mar 7 Assignment

molding, casting, and composites

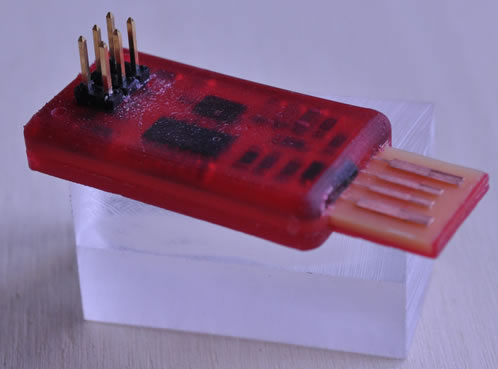

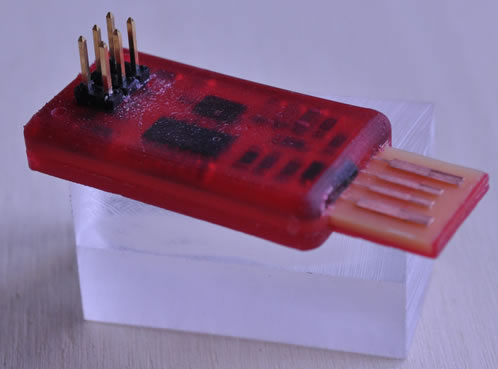

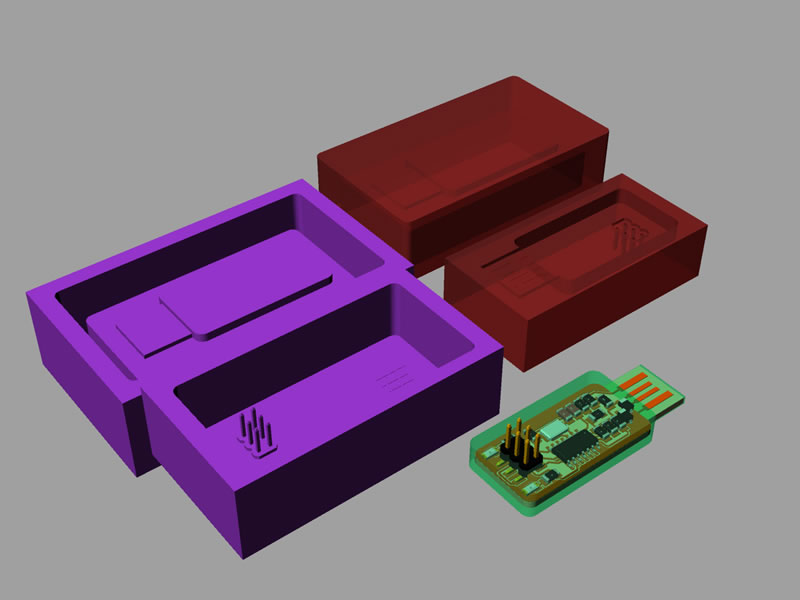

The plan is to cast my fabisp in a colored semi-transparant case.

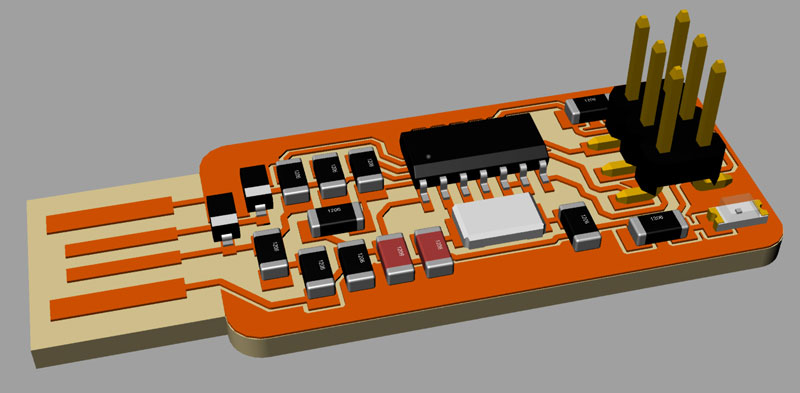

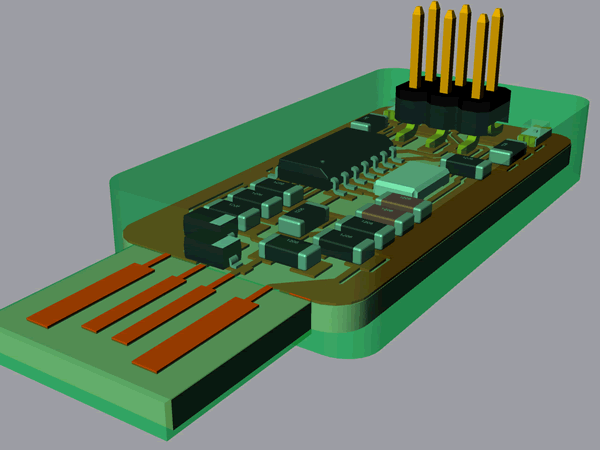

To prepare for that i created a 3D representation of my FabISP in Rhino. I did not model all the components myself, but i discovered a great source of casings and electronic components at 3D ContentCentral. Not only members add 3D models, but there are a lot og suppliers that upload content. The Models are available in a wide variety of formats. I opted to use IGES.

After making this model I started to have second thoughts about casting my isp in plastic as i din't know what the effects of the compounds on the citrcuit would be and it would prevent any future upgrade possibility.

I'm goin to drill the poor and airhholes into the urithane from the side.

Note: urithane needs to cure at elivated temperature

And, ofcource, this turned out to be a bad idea. The urithane is so flexible it is really hard to drill into.

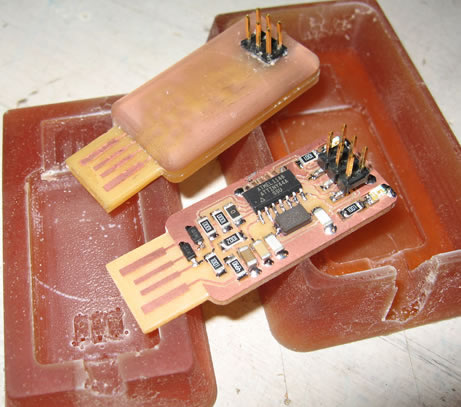

so for the second mold i added a pour-hole out of low-temp-wax

Filled it with the right amount of PMC® -121-30 Dry - Easy To Use Urethane Rubber. I calculated this amount trough Rhino.

And this turned out te be nicely melted after residing in the oven for an hour (at 150 deg F)

Next up (or down) is to make a second trial cast to test the new pouring hole

Another improvement i'm making is a pin that keeps the bord frimly pressed to the top-part of the mold.

so after this test i can conclude that i need to use more mold release. the two compounds still stuck heavely to each other. Also, come back to your freshly poured mold in about 3 hours. I needed to top up the mold because of shrinkage (the casting material i used has a pot life of 5 hours)

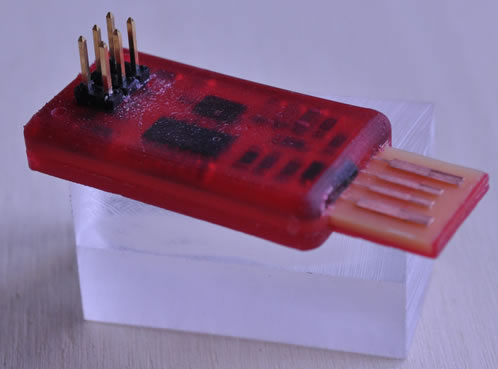

Finished casting