FAB ISP

SUMMARY:

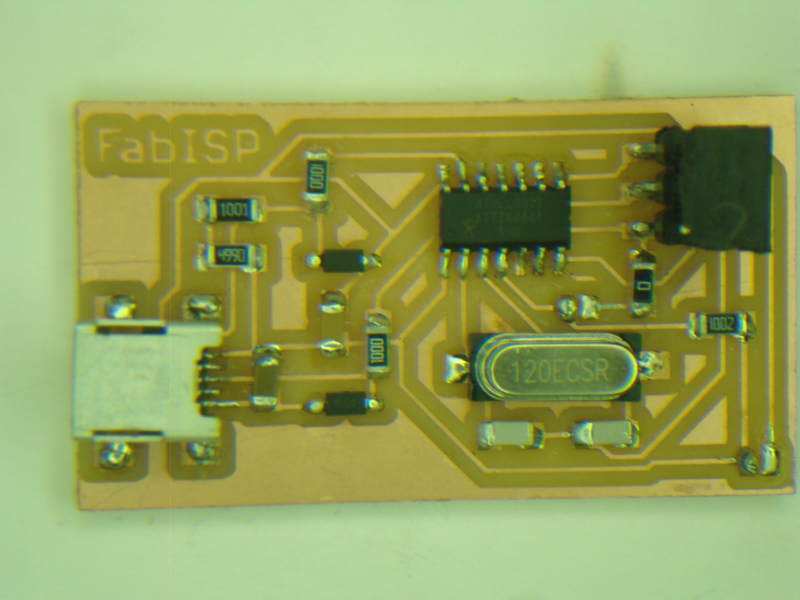

Our project for this week was to use the MIT fab module software to cut out a circuit board using FRS1 on the Modela MDX-20. We were provided with a png image of the ISP from the fab archive, which the fab modules rendered to a tool path, which was then output to the mini mill. It took about 30 minutes to cut out the board.

We then got to stuff the board. For a novice, it took quite a bit longer (several hours) to solder all the pieces to the board. The most time consuming part for me was the USB port, which had some insanely small traces requiring a soldered connection. Fortunately, I happen to have a binocular dissecting microscope, which at least helped me see what I was trying to do! With a bit of patience and practice, some skill was developed. The following photo set gives a close up view of some of the principal components as they were soldered to the board

COMPLETED BOARD

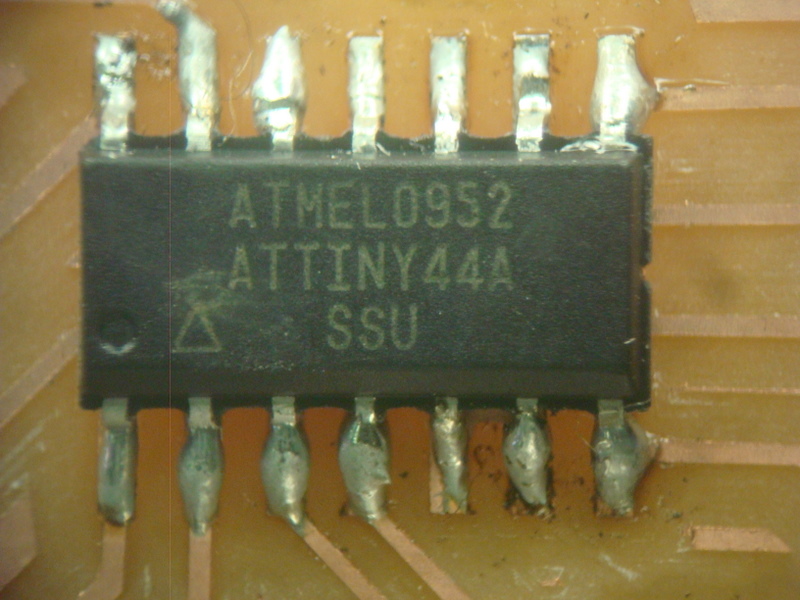

THE MICROPROCESSOR

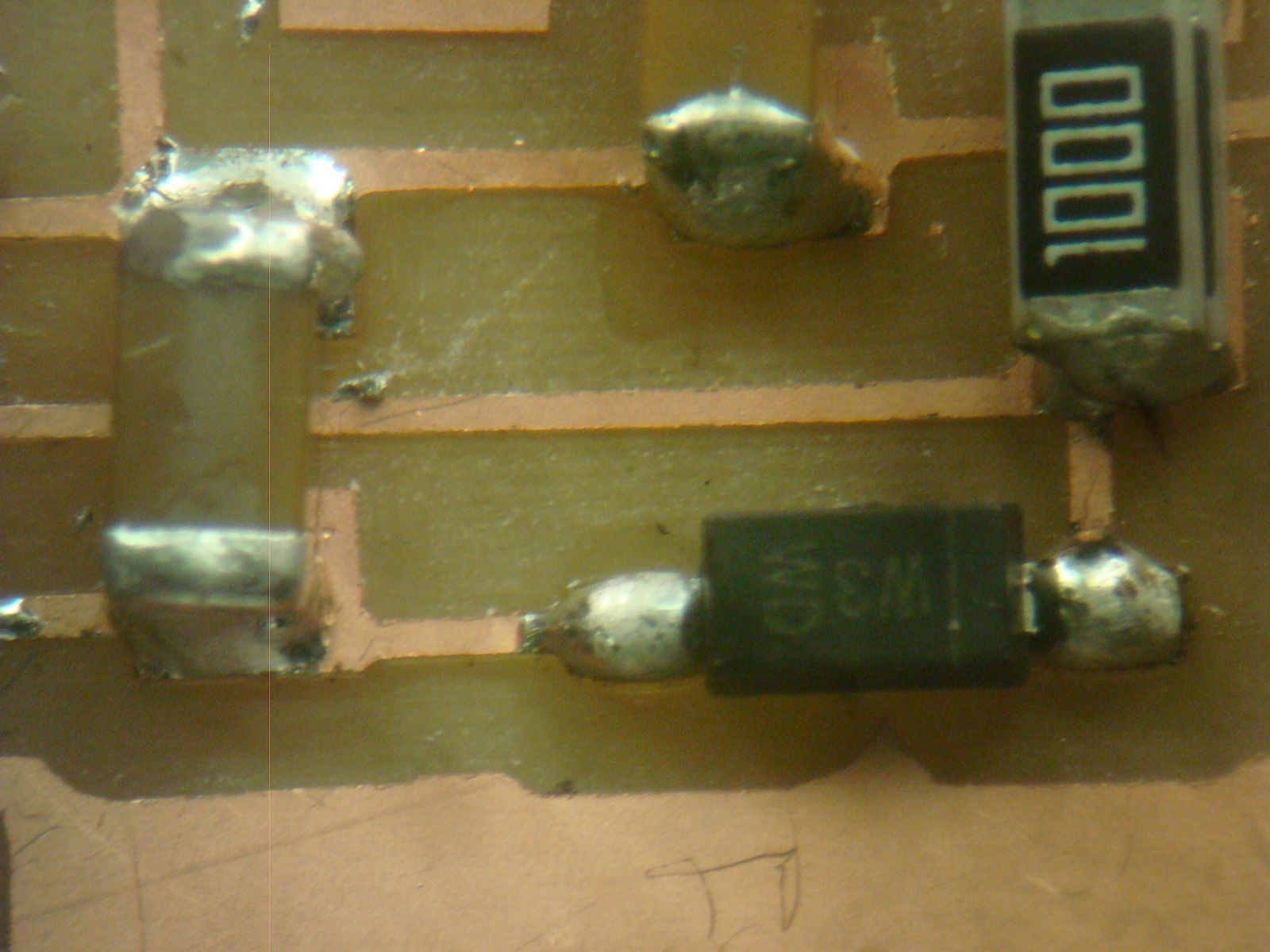

ZENER DIODE, CAPACITOR, AND RESISTOR

A couple of 18pF capacitors adjacent to the 12MHz crystal

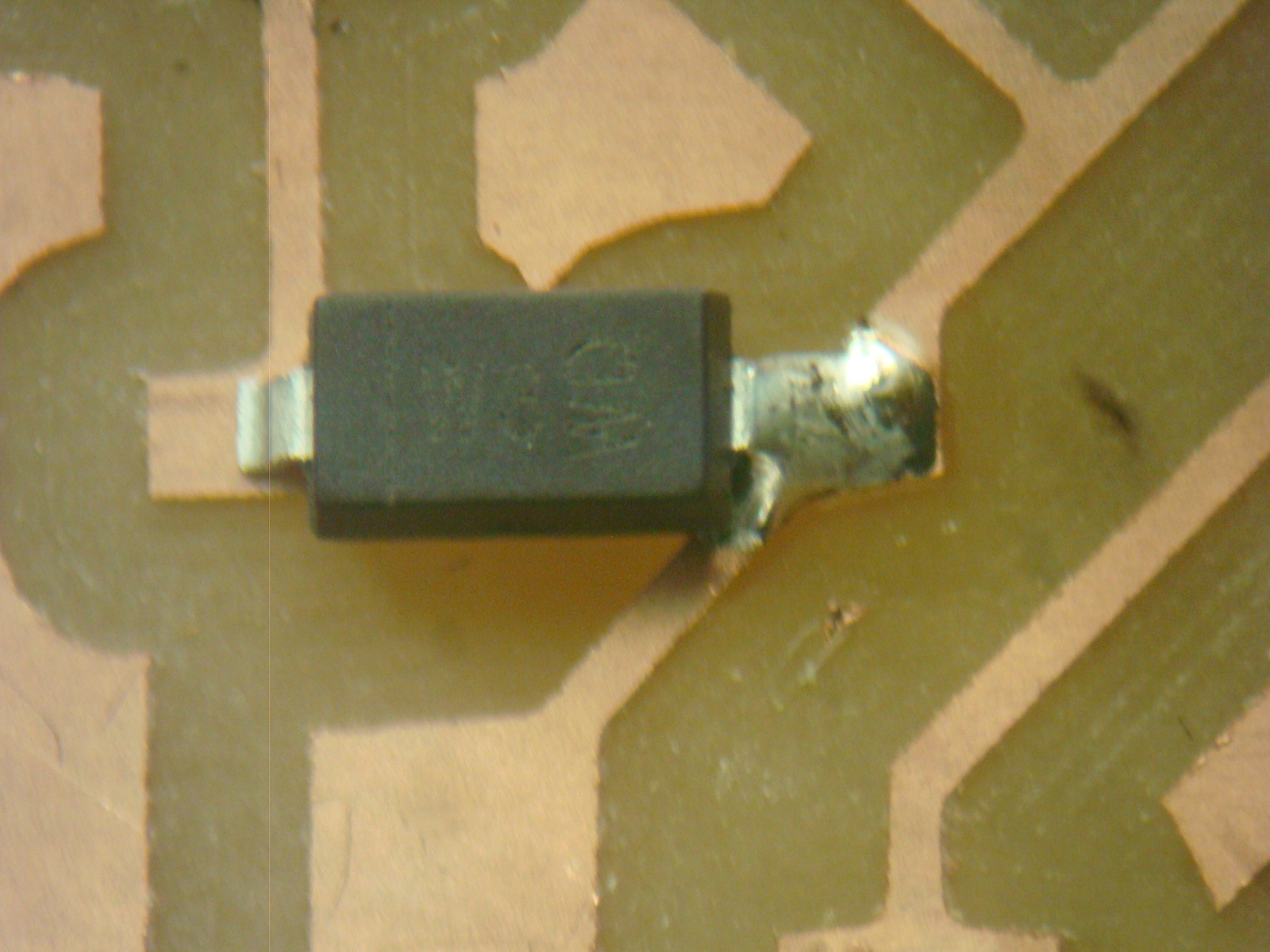

ZENER DIODE CLOSE UP

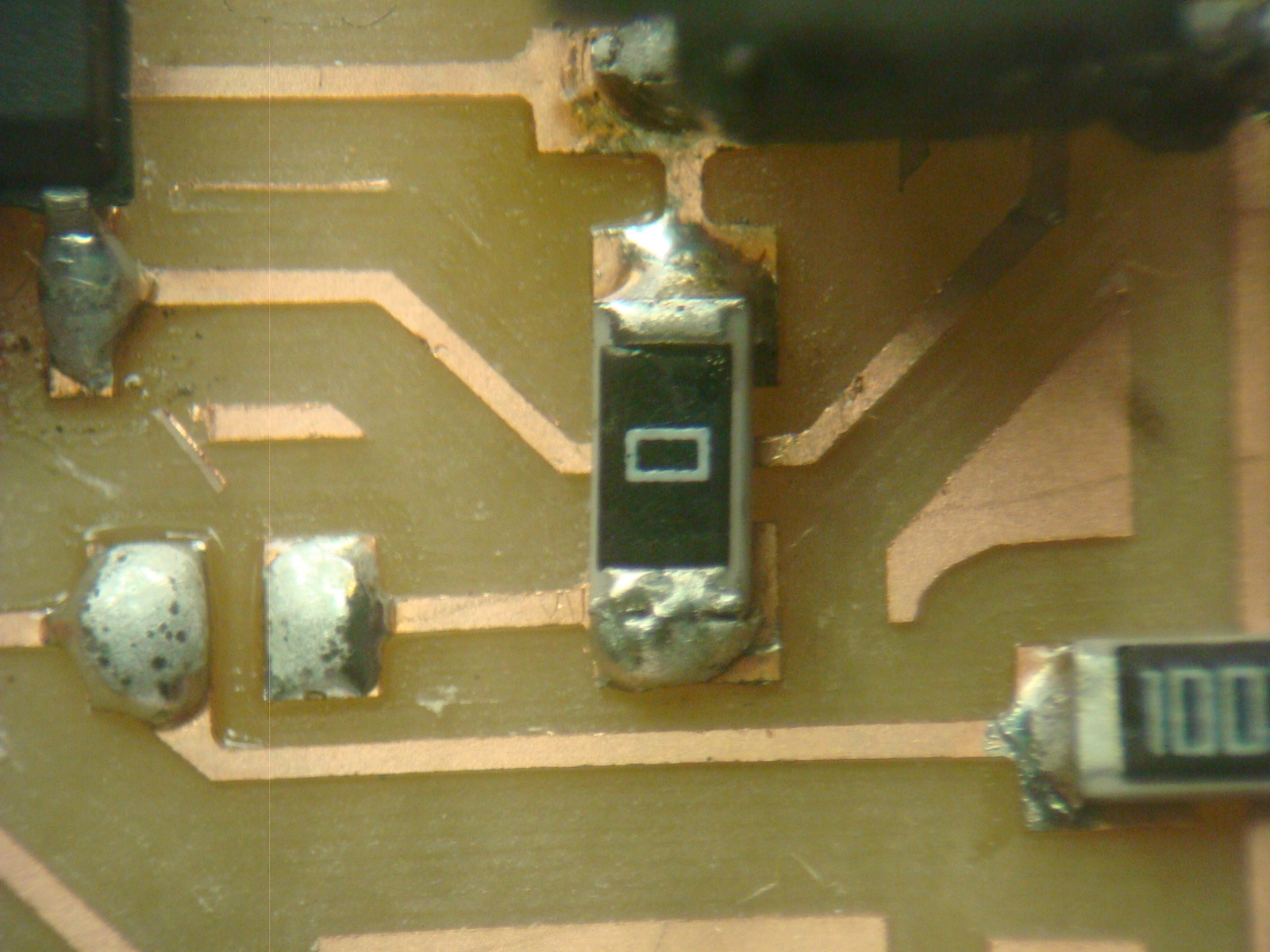

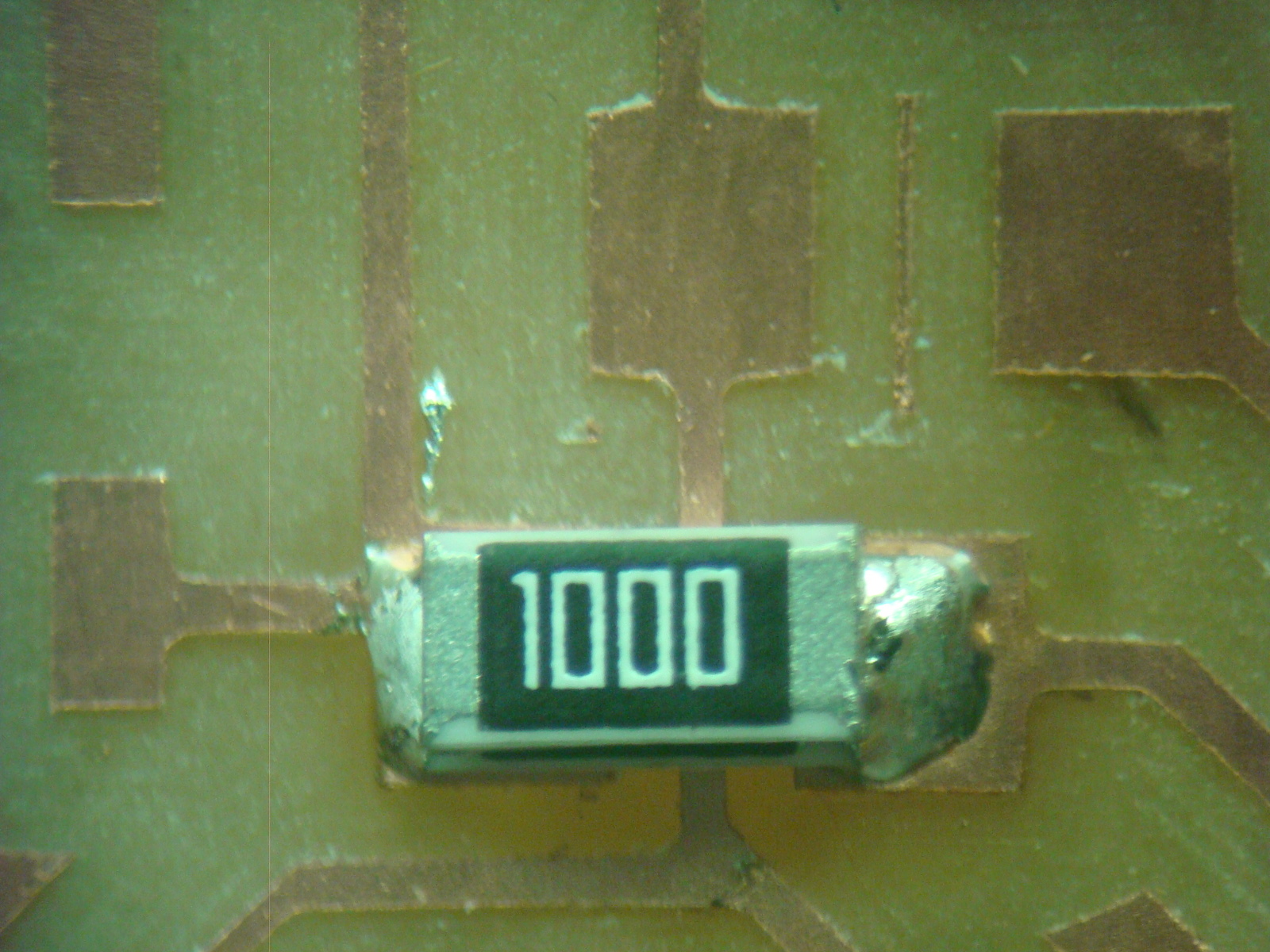

ZERO RESISTOR - USED TO CROSS A TRACE. NOTE THE SOLDER BLEBS TO THE LEFT, THESE WILL BE CLOSED TO PROGRAM THE BOARD, THEN REOPENED WHEN PROGRAMMING OTHER BOARDS

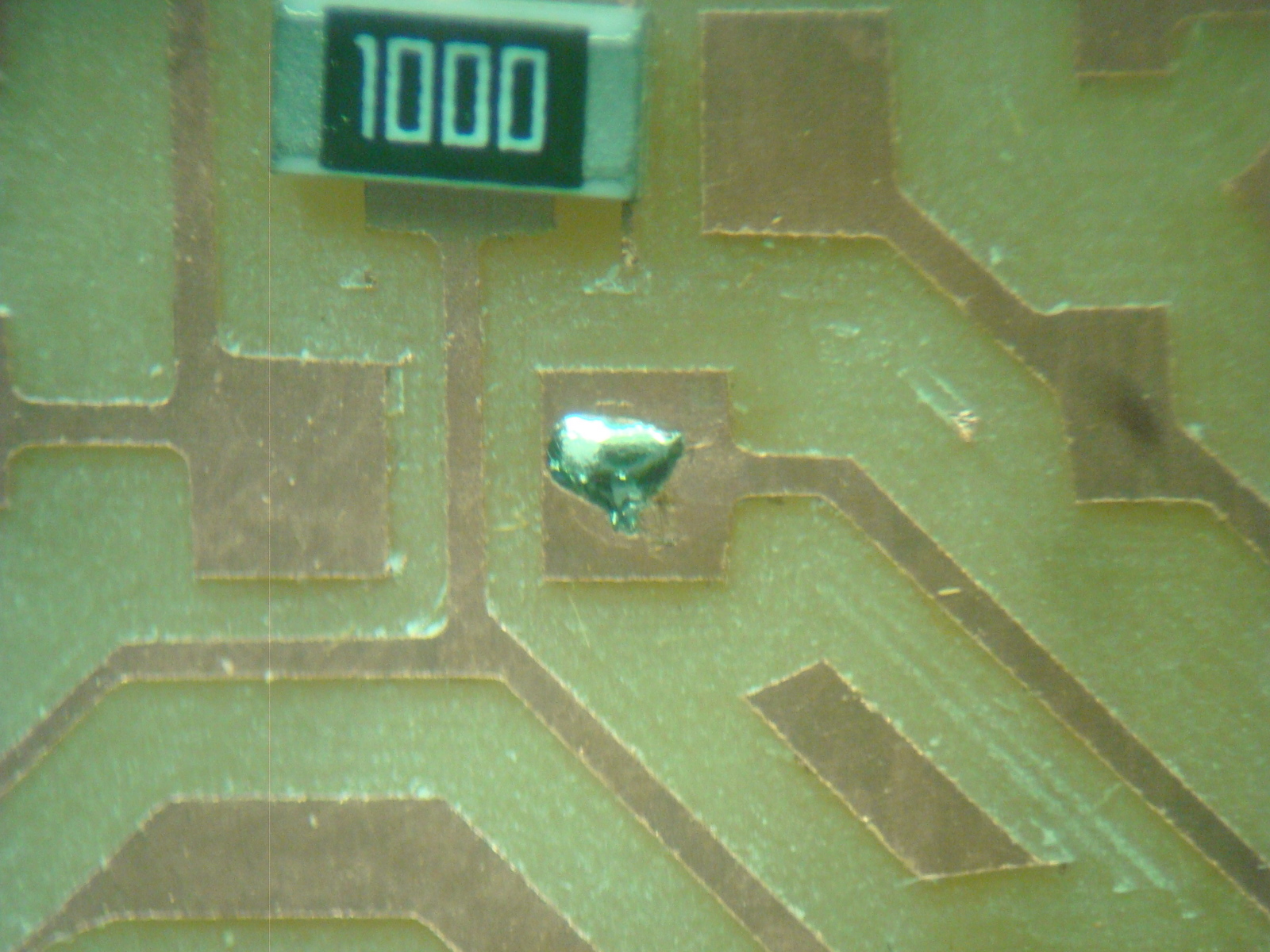

WETTING PAD WITH SOLDER

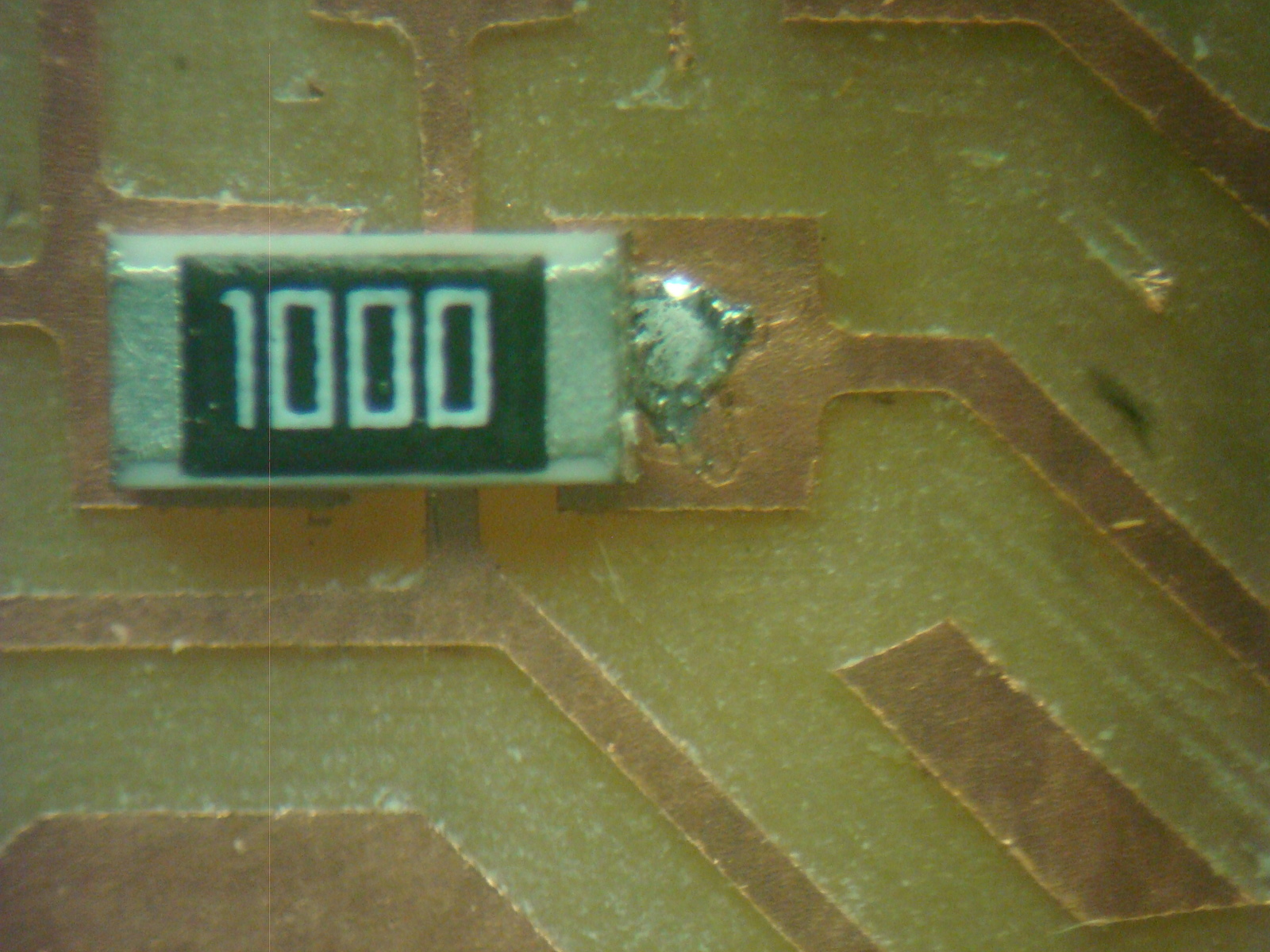

TACKING RESISTOR TO PAD

SOLDERED CONNECTION. NOTE THAT WE STACKED TWO 100 OHM RESISTORS IN PARALLEL TO YIELD A 50 OHM VALUE

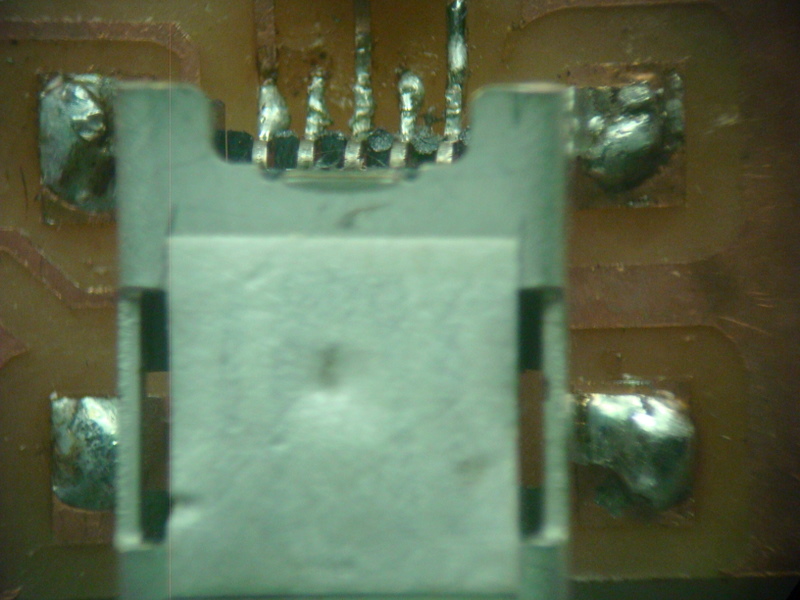

USB CONNECTOR

SOLDERED CONNECTION BEFORE PROGRAMMING

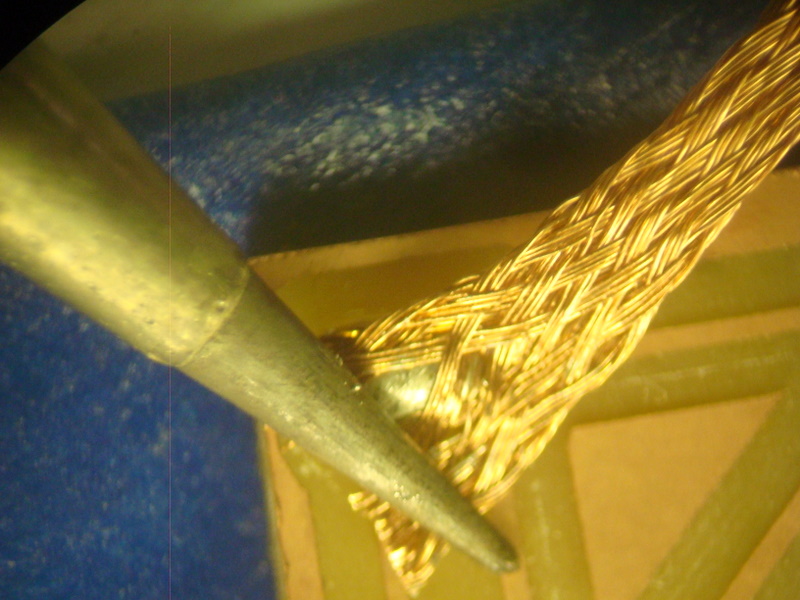

WICKING THE SOLDERED JOINT

READY TO PROGRAM OTHER CHIPS

DISCUSSION

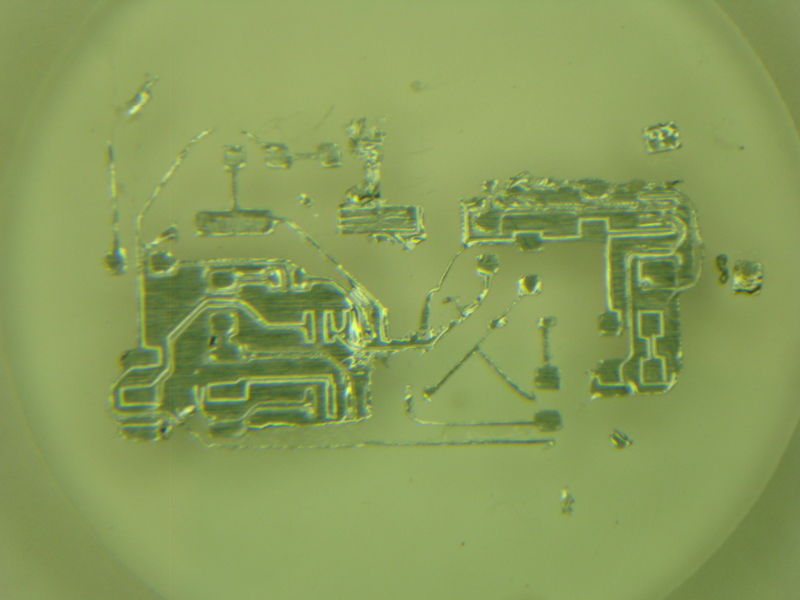

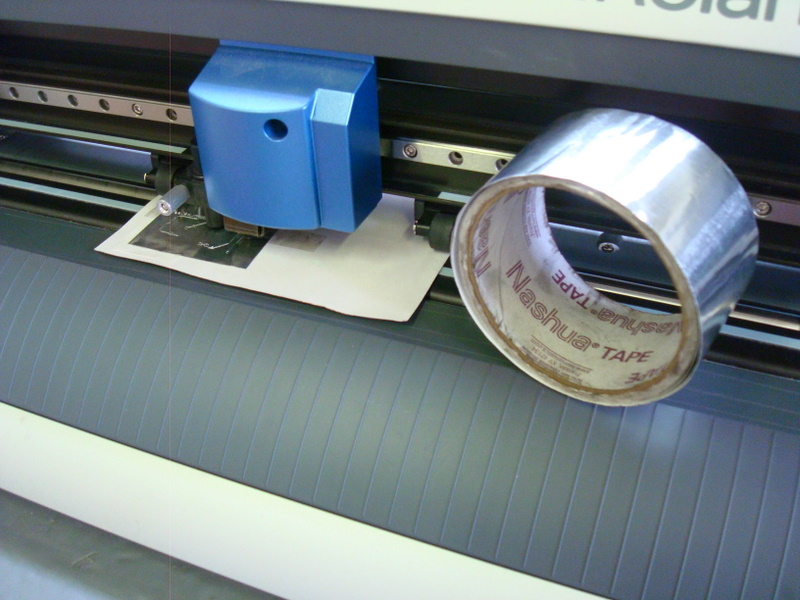

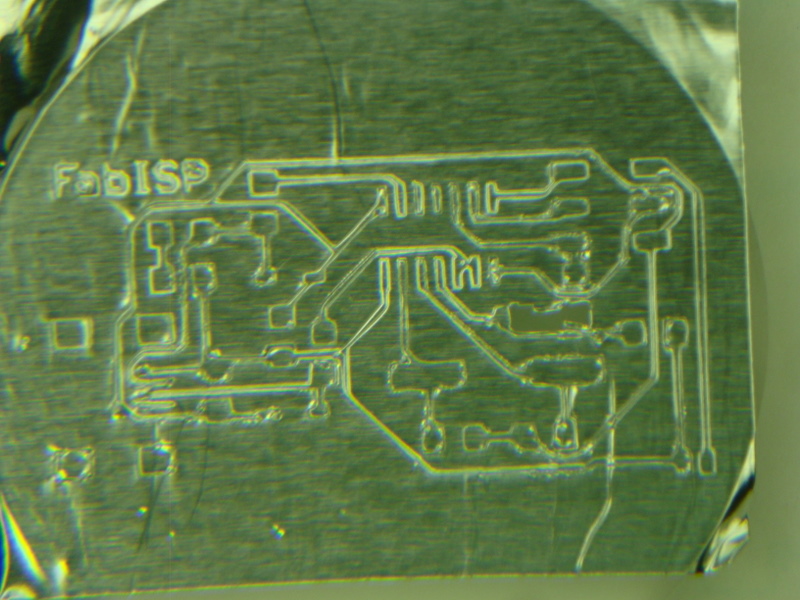

In addition to making the FabISP in the usual way, we also tried to use the vinyl cutter to make an equivalent board with sheet copper. Mercedes has an excellent example and tutorial on her website. I tried to "poor boy" it using aluminium duct tape. The result was something of a disaster in terms of a workable result, but holds promise for future work. One of the big problems is that the glue does not adhere to the acrylic wafer when soldering is attempted. I will try using "wire glue" next time and see how well that works. Here are a few photos which document these initial efforts.

CUTTING ALUMINIUM DUCT TAPE

TRANSFERRING TO ACRYLIC WAFER

TEST WEEDING