SUMMARY

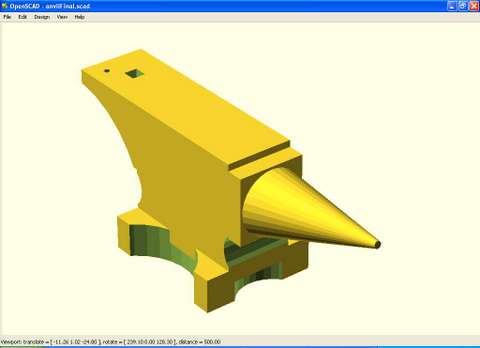

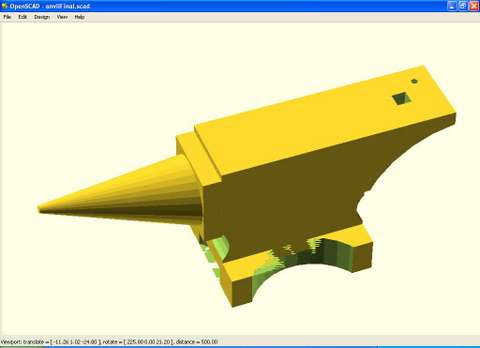

I used OpenScad to fashion a digital anvil. OpenScad is simple to install on most software platforms, and has an intuitive program structure which allows one to quickly assemble a 3D object.

I built the anvil from the base upwards, in a series of three layers. The base is a rectangular volume, with a portion of 4 cylinders subtracting material from the centre of each face. The middle layer is a taller and narrower rectangular volume, with two cylinders rotated 90 degrees (fore and aft), subtracting material forming the waist. The uppermost layer is formed by the union of one large rectangular volume for the face, a cone shaped volume for the horn, and a small joining rectangular volume which forms the table (often used for rough cutting, meant to be struck with a hot chisel). A large cylinder rotated 90 degrees subtracts material in a tapered wedge from the back of the anvil face. A hardy hole and pritchel hole were also subtracted, which in the physical world are used to accommodate tooling and permit hot punching.

Here is the OpenScad file used to generate the anvil:

difference(){

union(){

cube([40,34,10],true); //lowermost rectangular volume

}

translate([26,0,-5])cylinder(20,10,10);// these cylinders parallel to the z axis

translate([-26,0,-15])cylinder(20,10,10);// remove material from the face of the

translate([0,26,-5])cylinder(17,17,17);// above defined rectangle

translate([0,-26,-5])cylinder(17,17,17);

}

difference(){

union(){

translate([-20,-10,-20])cube([40,20,19]);// the middle volume, or "waist"

}

translate([-25,14,-11])rotate([90,0,0])cylinder(28,7,7);//This gives the anvil

translate([25,14,-11])rotate([90,0,0])cylinder(30,7,7);//the hourglass waist

}

difference(){

union(){

translate([-20,-10,-37])cube([65,20,20]);//anvil face

translate([-25,-10,-35])cube([5,20,20]);//anvil table

translate([-65,0,-32]) rotate([0,80,0])cylinder(43,1,10);//anvil horn

}

translate([48,15,-3]) rotate([90,0,0])cylinder(30,30,30);//forms tapered wedge

translate([32,-2,-40]) cube([4,4,20]);//Hardy hole

translate([40,-5,-40]) cylinder(20,1,1);//Pritchel hole

}

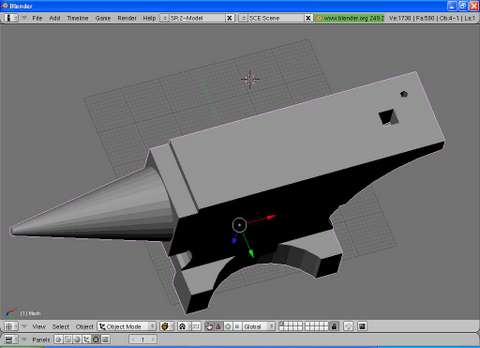

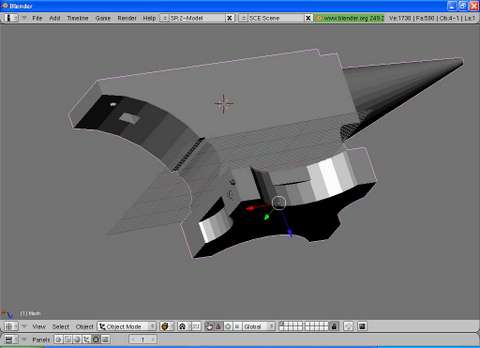

And here are rendered .stl files as displayed in the Blender environment:

DISCUSSION

Programmable Digital Fabrication

An anvil built out of plastic at this scale is strictly ornamental, but what might the future hold?

Part of this weeks lecture looked at the road ahead for tools and machines which will populate the fab lab in the future. 3D printers, scanners and software can be pretty expensive, and not all that intuitive to work with. The fab lab of the future will conceivable have digital "stuff" in the inventory which can be assembled into machines to perform particular tasks, and later recycled into different machines as new needs and understandings arise.

This raises a number of interesting thoughts on the relationship between man and material. One question concerning a programmable digital material (PDM), is whether or not it can program itself. PDM would presumably be a lifeless but orderable substance which could be assembled into useful stuff under the control of a program, which has an ultimate instantiation by mankind. Whatever separates organic growth of bacteria in a petri dish versus the self assembly of inorganic PDM would be an interesting distinction. Once bacteria runs out of sugar in an agar medium, or PDM runs out of electrical energy, activity is halted. In the case of the bacteria, it may die as a result. In the case of PDM, a new battery may change the properties of material from mere substance to substance with a mission.

One can imagine PDM assembled into a hammer. The properties of the hammer as normally understood need to be sensitive to the assignments to which a hammer is normally put, i.e. being heavy and hard, in order to do something useful, like drive a nail into a board. But a PDM could equally be assembled into a Non-Expanding Recreational Foam (NERF) hammer, in order to toss around in the back yard while playing with your dog. The promise here would be that one would never have a hammer which were too heavy or too light, and could simply free the PDM to respond to the assignment to which it is called. A well engineered PDM could assemble itself as it was being used in a range of activities, allowing the user to focus on the task at hand, without minding the hammer at all.