Molding and Casting

Group assignment

- Review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them

Materials used

Daniela

Some of the materials we used during this assigment are listed bellow, you can find the data sheet and safety instructions.

Decorlac Laca catalizada

Lacquer designed to give a durable and resistant finish to wooden surfaces. You can find the data and safety sheet in the following link:

Pinturas condor

Evans matt clear lacquer

Multipurpose spray paint based on acrylic resins, high covering power, wide variety of colors, point and fan nozzle. We used the matt and clear one

to give a finishing to our molds.

Evans

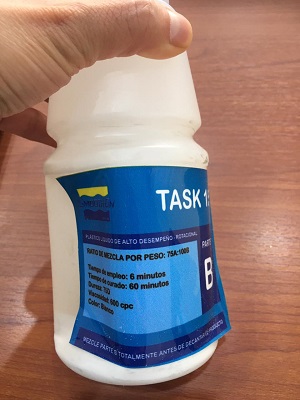

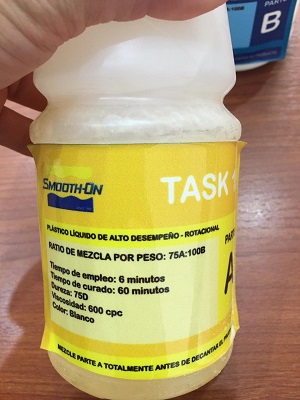

Smoot on - Task 16 urethane

TASK™16 is a low odor, fast-setting Shore 80A/30D urethane that offers very high tear strength, impact resistance and wear resistance.

You can find further information in this web site:

Smooth-on

Also the safety sheet:

Smooth-on

Ismael

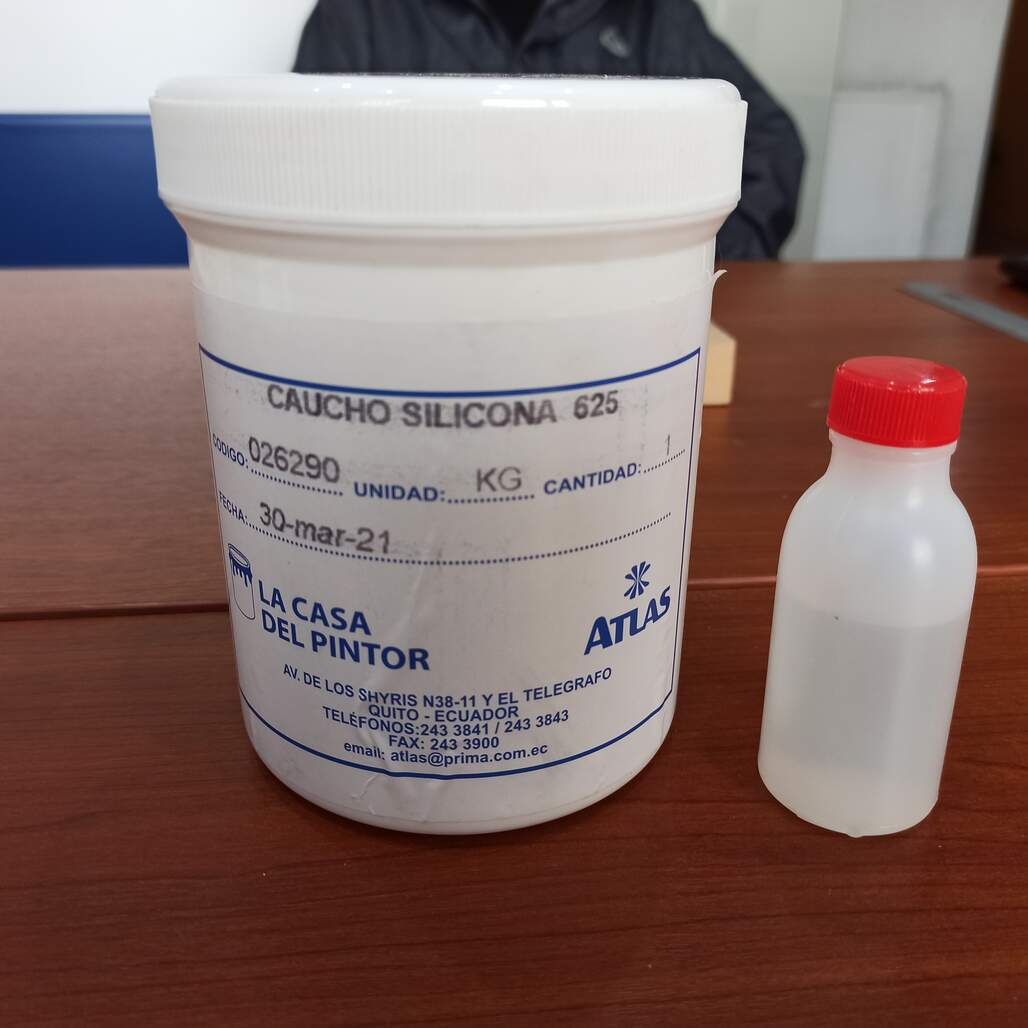

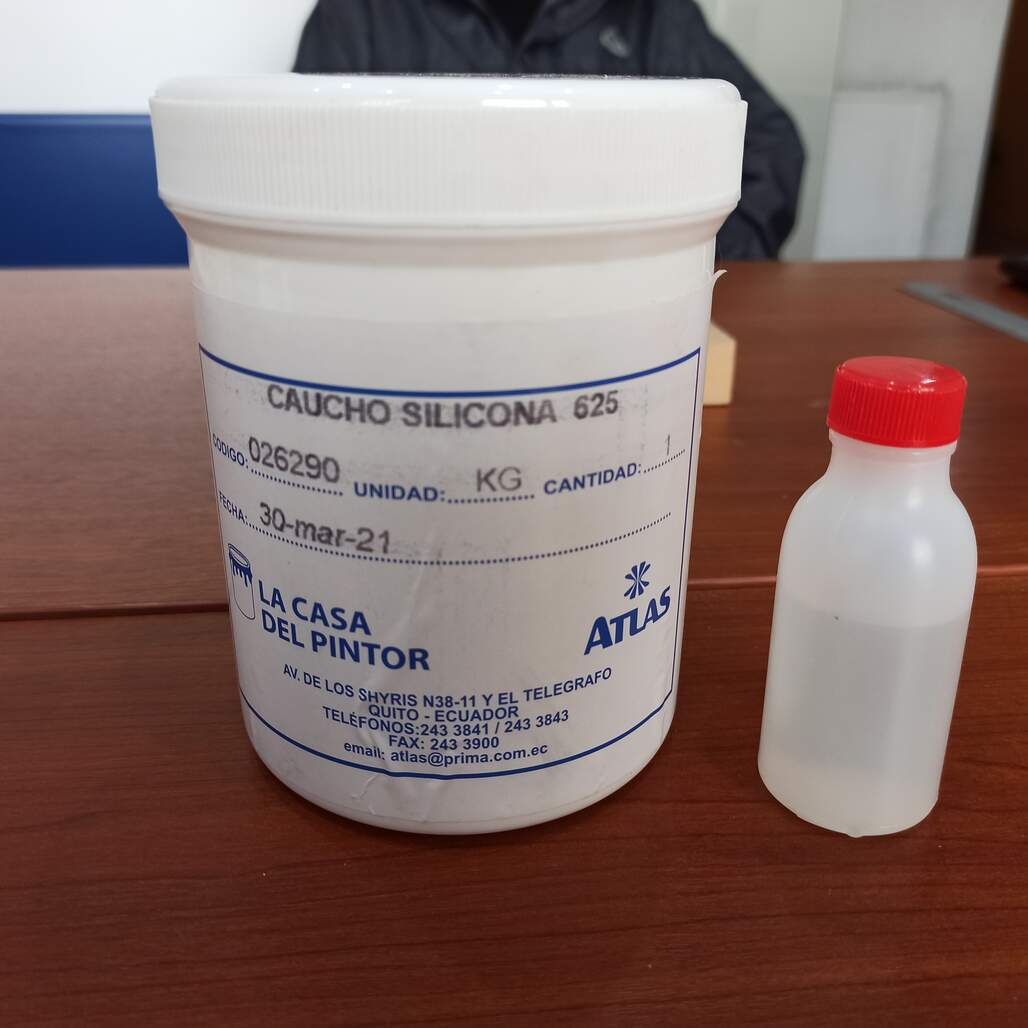

Silicone Rubber 6255

This is a 'safer' material, used to cast the mold were the final piece will be casted.

- Use protective gloves and safety glasses to minimize contamination risk.

- Always wash you hands after manipulation this product.

- Flush with abundant water on accidental contact with you skin.

EpoxAcast 690 - Smooth-On

Image from Smooth-On web page

Used to create a clear cast that will have LED lights embedded.

Is important to remember these points while working with this material:

- Use protective gloves, eye protection and a breath mask.

- Always wash your hands after manipulating this product.

- On an accidental contact with skin and/or eyes flush with plenty of water, use soap if on the skin.

- If inhaled, move the victim to fresh air, if needed provide artificial respiration and oxygen. Contact a physician immediately

Jeffery

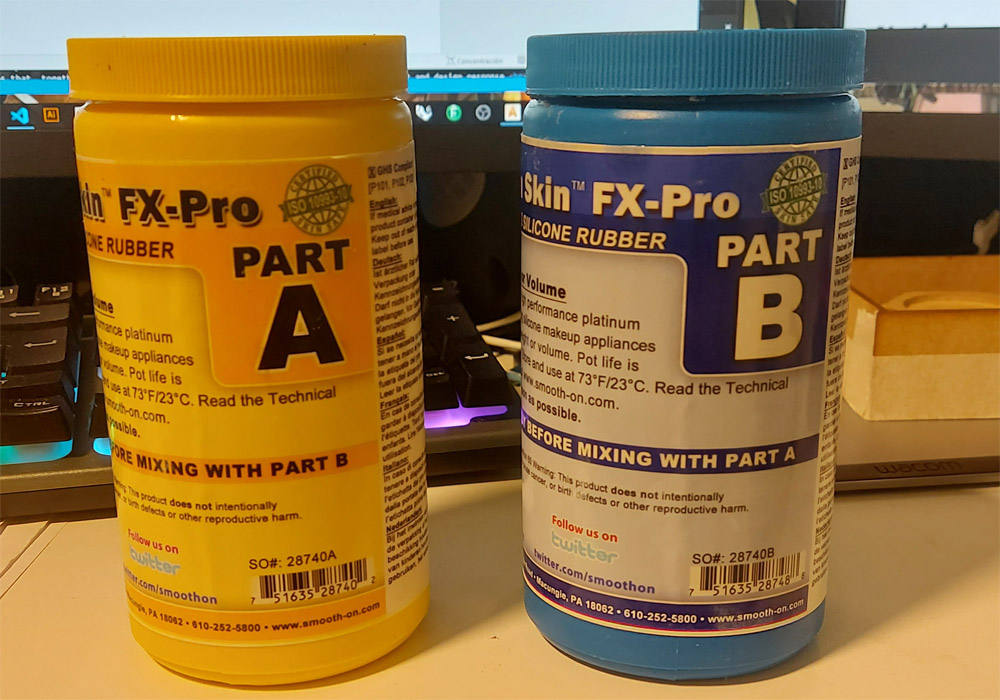

Dragon Sking FX-Pro

Dragon Skin™ FX-Pro is a soft, stable, high performance platinum silicone rubber specifically designed for creating silicone makeup appliances and skin effects

Dragon Skin™ FX-Pro is a soft, stable, high performance platinum silicone rubber specifically designed for creating silicone makeup appliances and skin effects

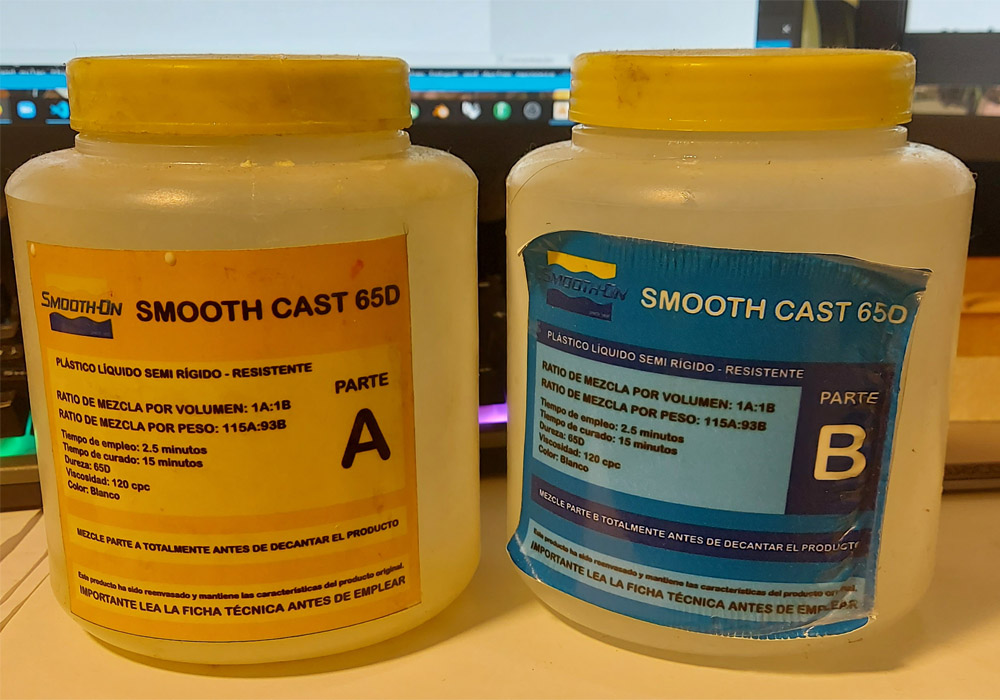

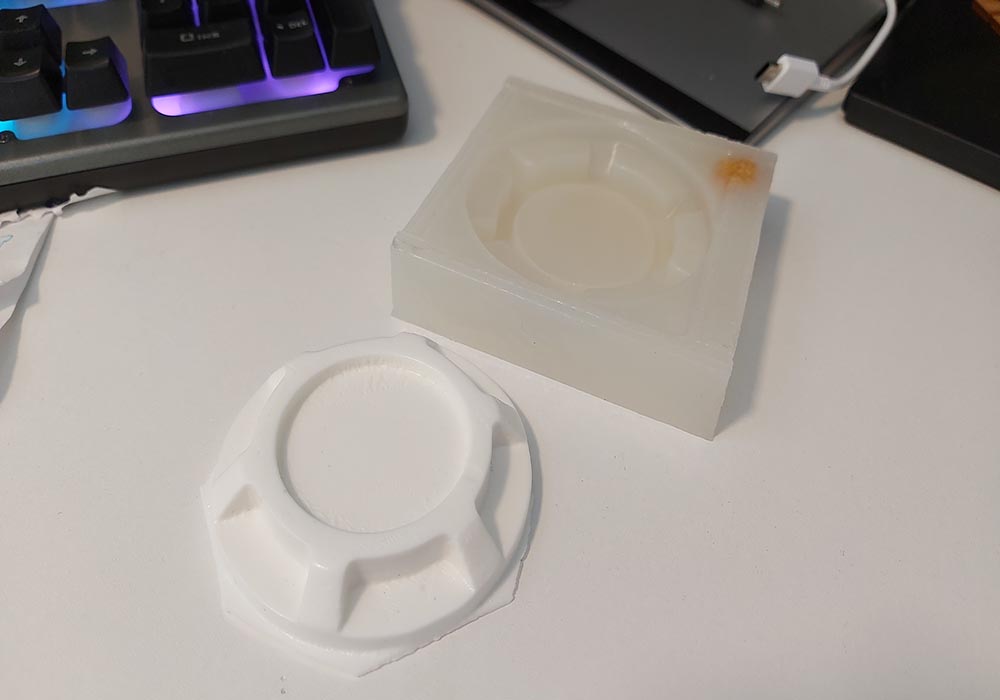

Smooth-ON Smooth Cast 65D

The Smooth-Cast™ Semi-Rigid line of low-cost semi-rigid urethane casting resins cure quickly to semi-rigid plastics that offer excellent impact resistance. These plastics are easy-to-use

(mix ratio is 1A:1B by volume) and have low viscosities for minimal bubble entrapment. Vibrant colors are possible by adding SO-Strong™, UVO™ or Ignite™ color pigments.

The Smooth-Cast™ Semi-Rigid line of low-cost semi-rigid urethane casting resins cure quickly to semi-rigid plastics that offer excellent impact resistance. These plastics are easy-to-use

(mix ratio is 1A:1B by volume) and have low viscosities for minimal bubble entrapment. Vibrant colors are possible by adding SO-Strong™, UVO™ or Ignite™ color pigments.

EpoxAcast 690 - Smooth-On

After the casting this piece has a great transparent look, but it also capture the texture of the mold that wasn't sanded down, it creates a nice 'glow' effect when the led's are turned on.

When fully cured it also has rigid and strong feel, that can easily support itself on the tree shape.

Compare Material Properties

| Material | Description | Picture | Working time | Cure | Comments |

|---|---|---|---|---|---|

| Silicone Rubber 6255 | Silicone rubber is a high-performance elastomer characterized by an unusual combination of properties. These properties range from high temperature performance to durability, excellent electrical insulation properties |  |

15 minutes | 24 hours at room temperature | Material used to cast the mold, has to be poured very slow to avoid the bubbles. |

| Smooth On - EpoxAcast 690 | EpoxAcast™ 690 is a clear casting epoxy resin suitable for a variety of industrial and art-related projects requiring a rigid, clear finished casting. It is mixed 100A:30B by weight (gram scale required) and features a very low viscosity for easy mixing and minimal bubble entrapment |  |

5 hours | 24 hours at room temperature | Result is clear, has to be poured very slow to avoid bubbles. |

| Smooth On - Task 16 | TASK™16 is a low odor, fast-setting Shore 80A/30D urethane that offers very high tear strength, impact resistance and wear resistance |  |

6 minutes | 90 minutes | The result is white, needs to be poured slowly to avoid bubbles. |

| Dragon Sking FX-Pro | Soft - Shore 2A hardness allows for softer appliances using less SLACKER™ deadening agent Low Viscosity - combined with long working time reduces bubbles and makes pouring easier |  |

12 minutes | 45 minutes | Will not leach silicone fluid |

| Smooth-ON Smooth Cast 65D | These plastics are easy-to-use (mix ratio is 1A:1B by volume) and have low viscosities for minimal bubble entrapment. Vibrant colors are possible by adding SO-Strong™, UVO™ or Ignite™ color pigments. |  |

2-5 minutes | 15 minutes | Cured castings are semi-rigid and impact resistant. They resist moisture, mild heat, solvents and can be primed/painted or bonded to other surfaces sing Urebond or similar flexible adhesive. |