10. Mechanical design & Machine design¶

Task: Mechanical Design, Machine Design

Mechanical Design (part 1 of 2)¶

- Group assignment:

- Design a machine that includes mechanism + actuation + automation

- Build the mechanical parts and operate it manually.

-

Document the group project

-

Individual assignment:

- Document your individual contribution.

Machine Design (part 2 of 2)¶

- Group assignment:

- Actuate and automate your machine.

- Document the group project

- Individual assignment:

- Document your individual contribution.

Components¶

Mechanical Components:¶

For this project we need the following Mechanical components

Electronics Components:¶

Also I searched for Electronics components that we need for this project.

3D Design & 3D Assembly¶

Stepper Motor¶

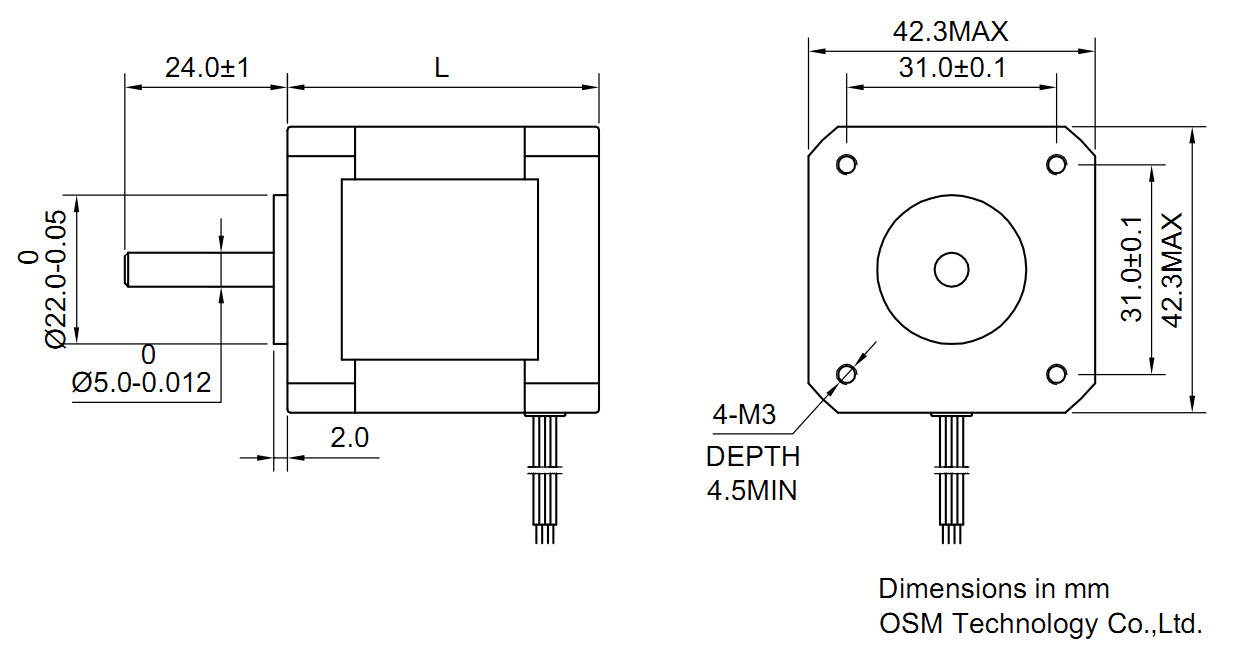

- For Stepper Motor we used the NEMA 17 motor and create sketch and 3d Module base on the standard dimensions for NEMA 17 from https://reprap.org/wiki/NEMA_17_Stepper_motor

- For the Nut I used Caliper tool to measure the dimensions of the bearing to Design Nut

Bearing¶

- For the bearing I used Caliper tool to measure the dimensions of the bearing

Z-Axis Part¶

- My part in this project is to design Z-Axis part which will carry the spindle part.

-

3D Assembly¶

Using Joint tool in fusion 360 to assemble 3D parts together

-First of all I have to assemble Z-Axis part with the spindle holder part.

I found that there is no space for bearing in the spindle holder.

-

Second Assembly after update the spindle holder design

-

After assembling all parts together, we need to make sure that is no interference between parts by using interference check tools in fusion 360

-

Assembling X-Axis parts together

-

Assembling Y-Axis parts together

-

Now to assemble all machine Axis together

3D Printing¶

For fabricating the part I decided to use 3D printing, because the part is very complicated and can’t be with ShopBot or laser cutting machine.

I used Ultimaker Cura Software and Ultimaker 3 Extended 3D printer.

-

I open the STL file with Ultimaker Cura software and I apply the following setting with support

-

The printing failed to print.

- I change the setting of the printing as following setting without support.

- Also I covert the printer with acrylic sheet to prevent the cold air form the Air-Condition

- The part was successfully printed

- Insert the bearings

- Insert the motor

Assembly¶

Here the part after Assembly with anther components

Software¶

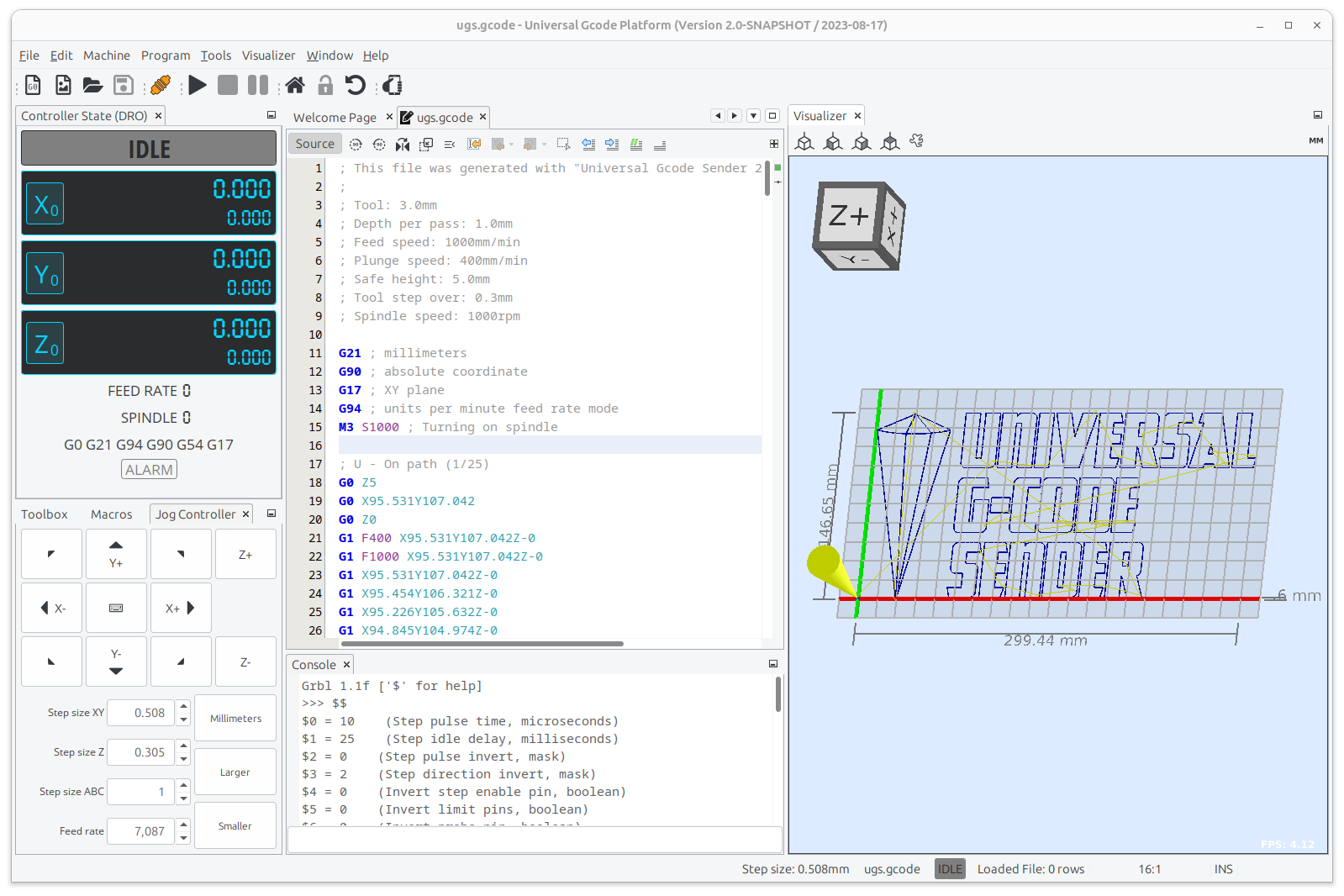

Download Universal Gcode Sender software from github

Testing¶

For testing I need to create ToolPath and export G-code to UGS in order to test the machine

Here is very helpful tutorial Making TOOLPATHS and exporting G-CODES | Fusion 360 | Quick Tip

I followed the Tutorial and I made a simple Design and Generate a toolpath using fusion 360

Test 1¶

To fix this issue I follow this video Fixing Fusion360 GRBL Post Processor

Test 2¶

Now the machine is working successfully