week5

This week’s task: make an in-circuit programmer by milling and stuffing the PCB, test it, then optionally try other PCB processes

PCB fabrication requirements

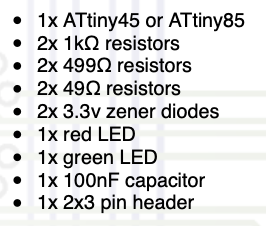

- components

- Designing the schematic and board

- milling

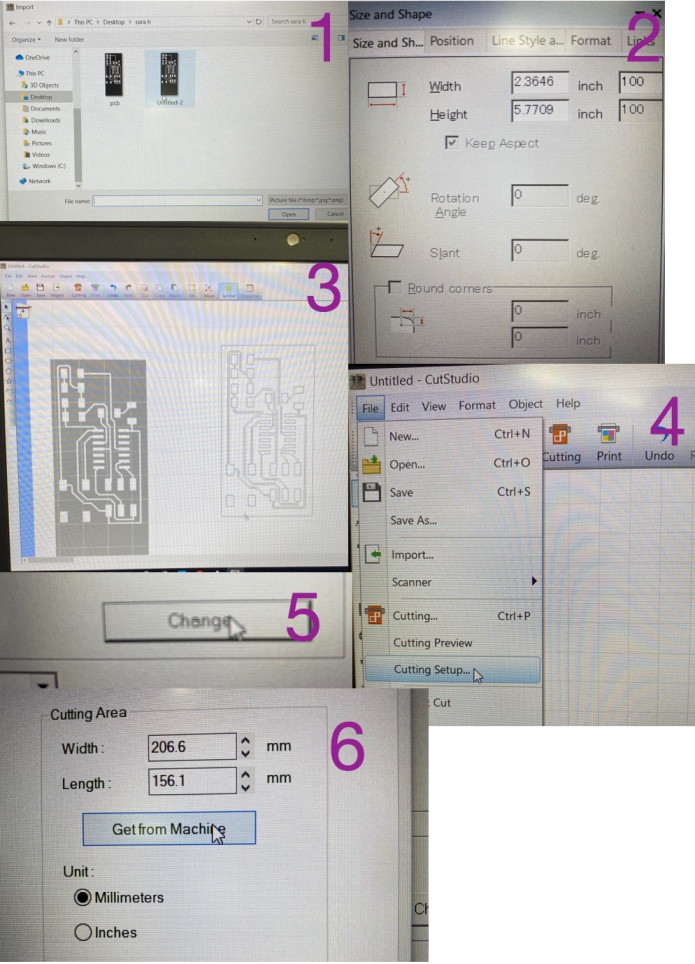

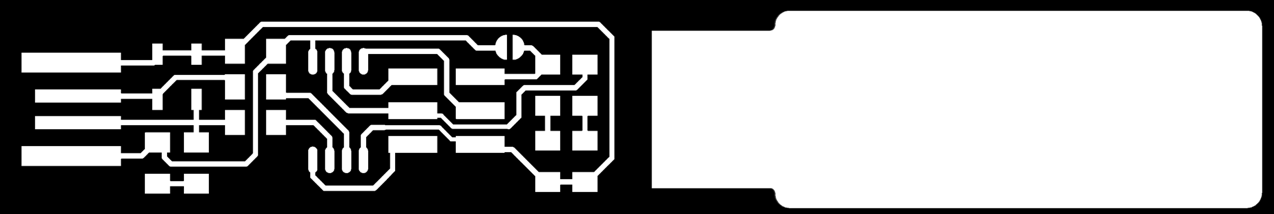

- Downloaded the traces and outline from fabacademy website

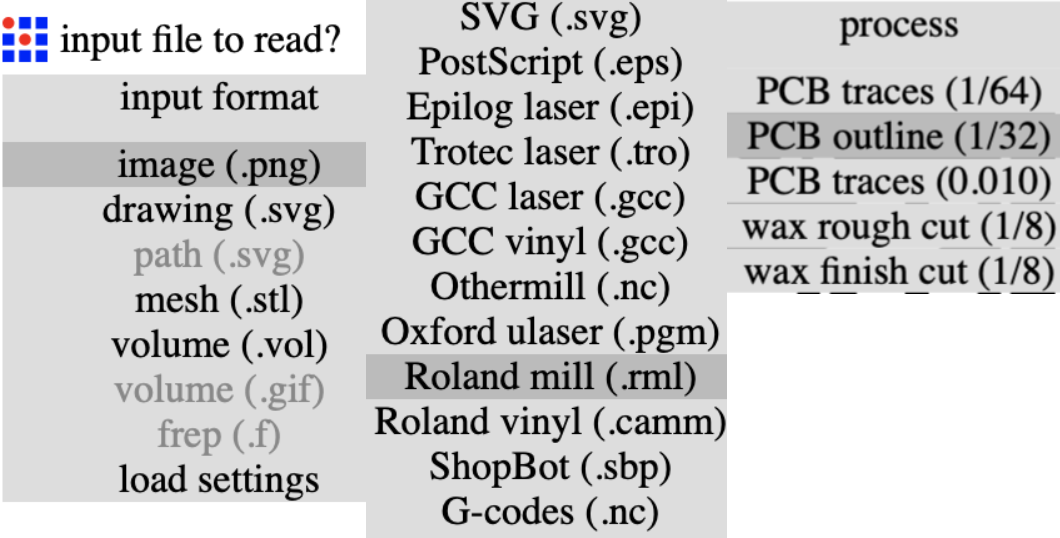

- Open fab modules and edit the setting for both traces and outline

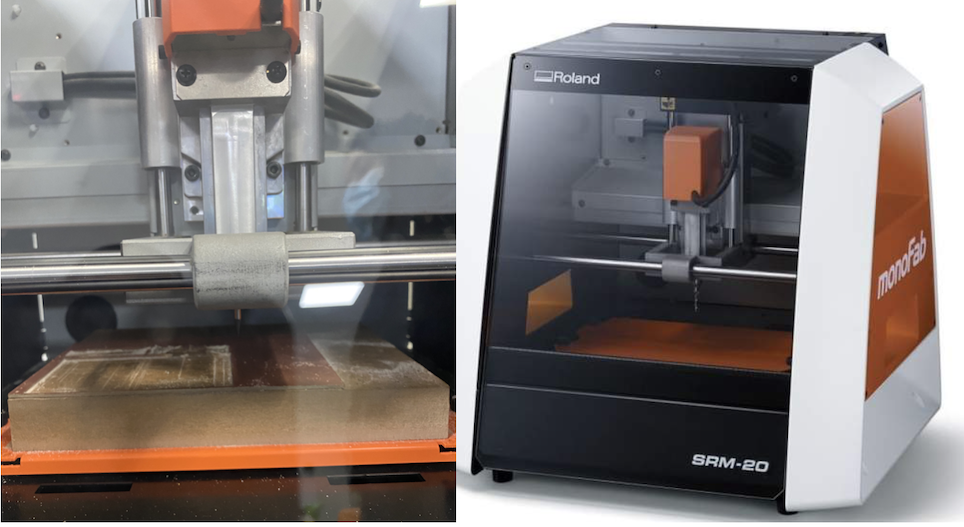

- Then click on Roland mill because it is the provided machine in our Fablab

- I changed some setting according to what our instructor gave us, and kept the rest as it was in default

- click on save then save as rml

- i inserted my usb to the laptop connected to the milling machine

- click on the Vpanel for SRM20 icon to launch the software

- edit the setting and move the arrows xy and z for accurate placement

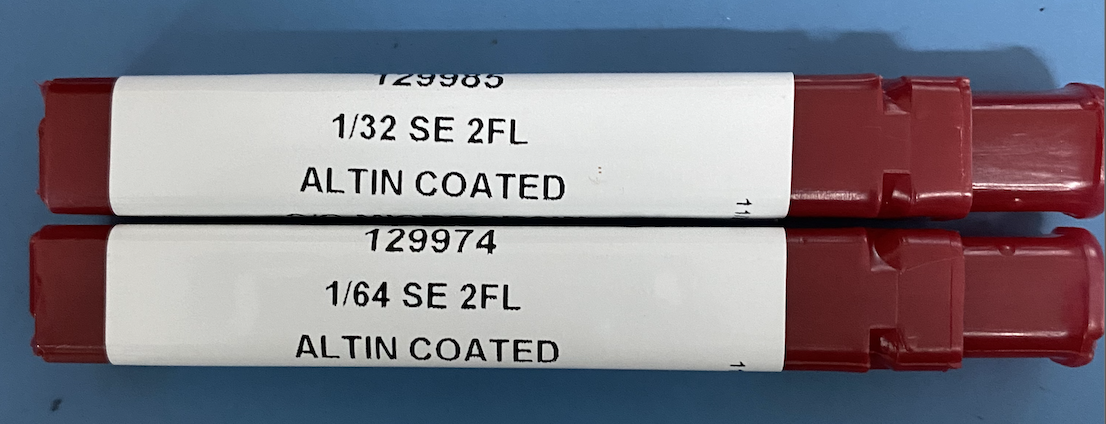

- i chose the shorted needle 1/32 for the outline and longer needle 1/64 for the traces

- i started with the design because i dont want the plate to move and ruin placement

- to prepare the surface, first i took the metal place and taped it with strong adhesive to a square mdf board

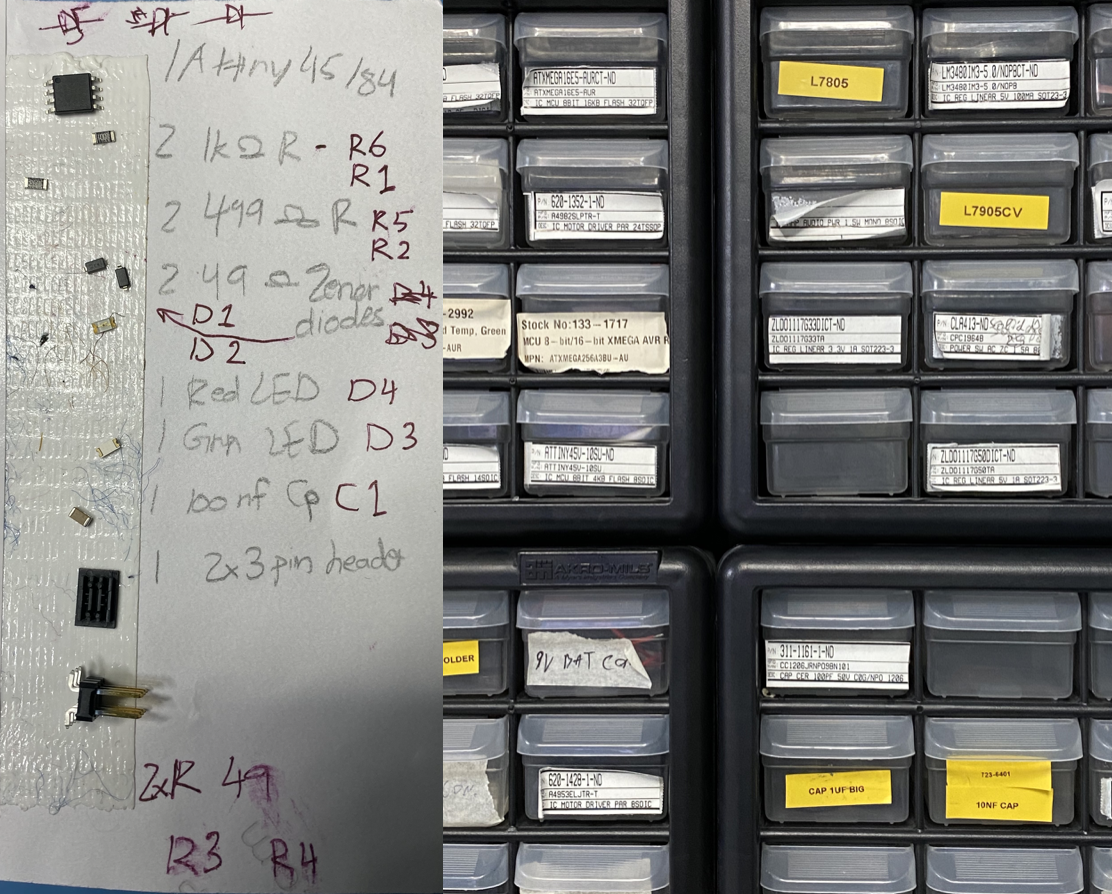

- collect all the components together

- these are the components i used and i got the list from fabacademy website page

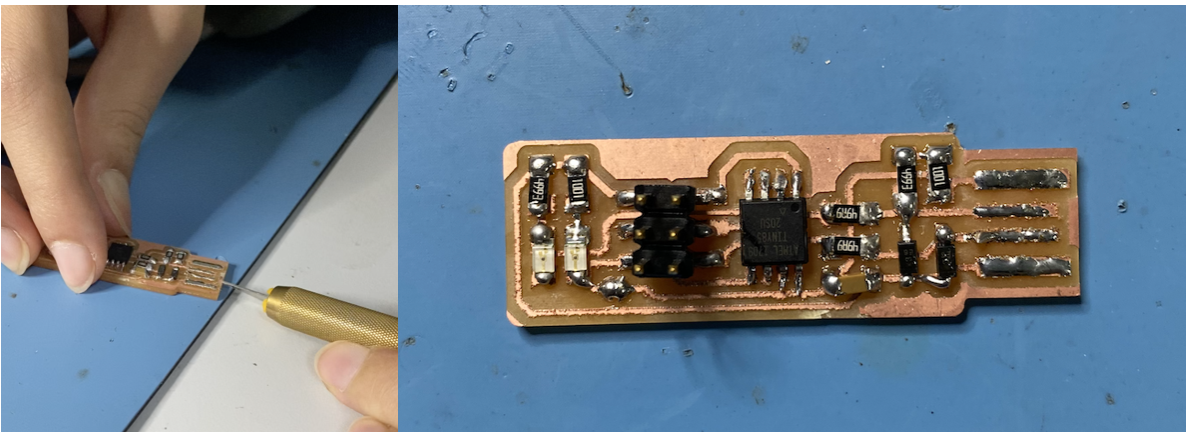

- first use an iron to heat pcb's pad

- while it heated, add abit of solder

- hold the components with a tweezer because the pad and the iron is hot and can get dangerous

- add solder to the top of each components but make sure you dint overlap the areas because it could cause a short circuit

- remove this part of the pcb

- this is the final look of the PCB

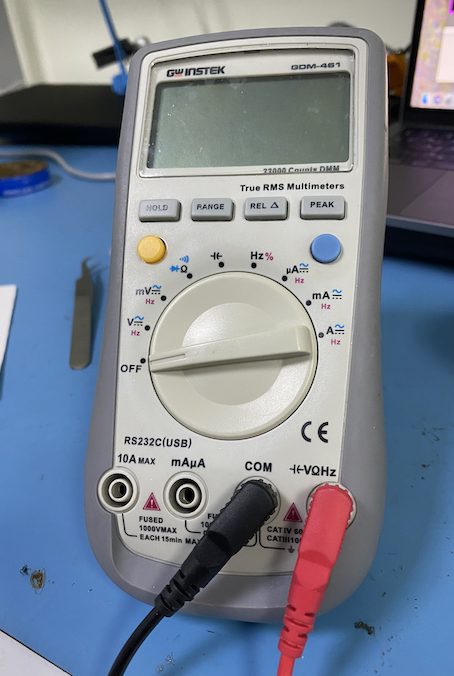

- before starting to program,check for any short circuit by using a multimeter

- for this step i followed fatma's programming page

- i started by downloading homebrew to downlaoad the other softwares i needed

- lastly restart terminal, then check if the programs are installed correctly

- next i opened firmware folder after downloading it

- then type "make" in the terminal to get the hex file

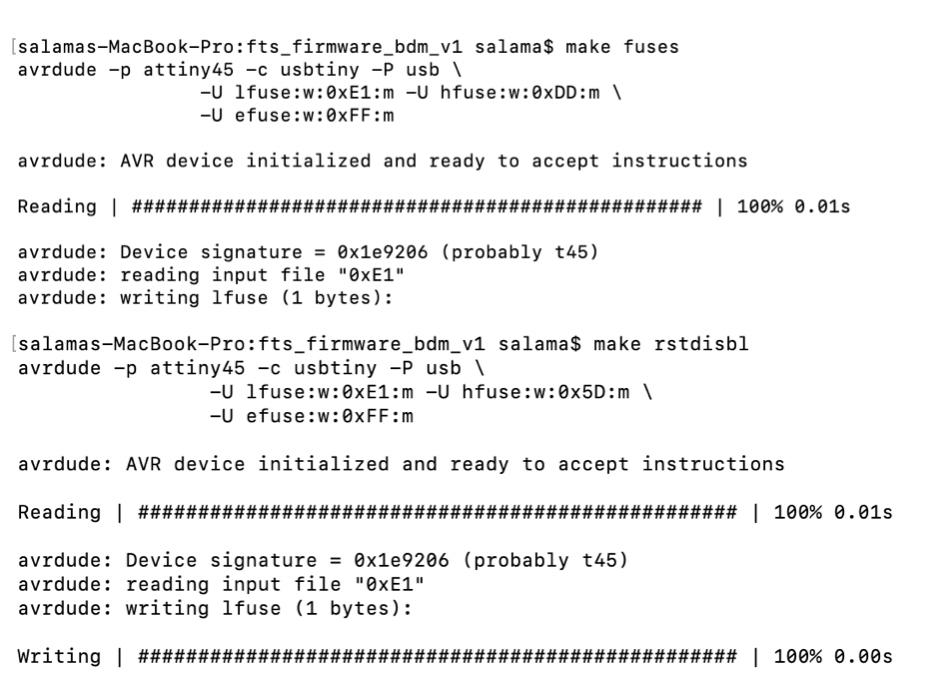

- get in desktop > fts_firmware_bdm_v1

- check if the fabisp is connected by clicking on about this mac > system report > usb

- if the isp showed in the usb tap it means it was successfully connected

- the isp's light is working and the laptop recognised it

- i printed using sara's design

- i cut out the design and removed the exrra carefully using an xacto knife and a tweezer

- then i sticked the pcb to a transfer sheet

- then cut out a piece of acrlyic using the lasercut machine and placed it underneath the pcb

Steps I followed to make the pcb

for engraving:

for soldering:

programming:

brew tap osx-cross/avr

brew install binutils

brew install gcc

brew tap osx-cross/avr && brew install avr-gcc

brew install avrdude

avr-gcc --version

make -v

open terminal

make flash

make fuses

make rstdisbl

group task:

i made a flexible pcb using vinyl cutter machine

steps: