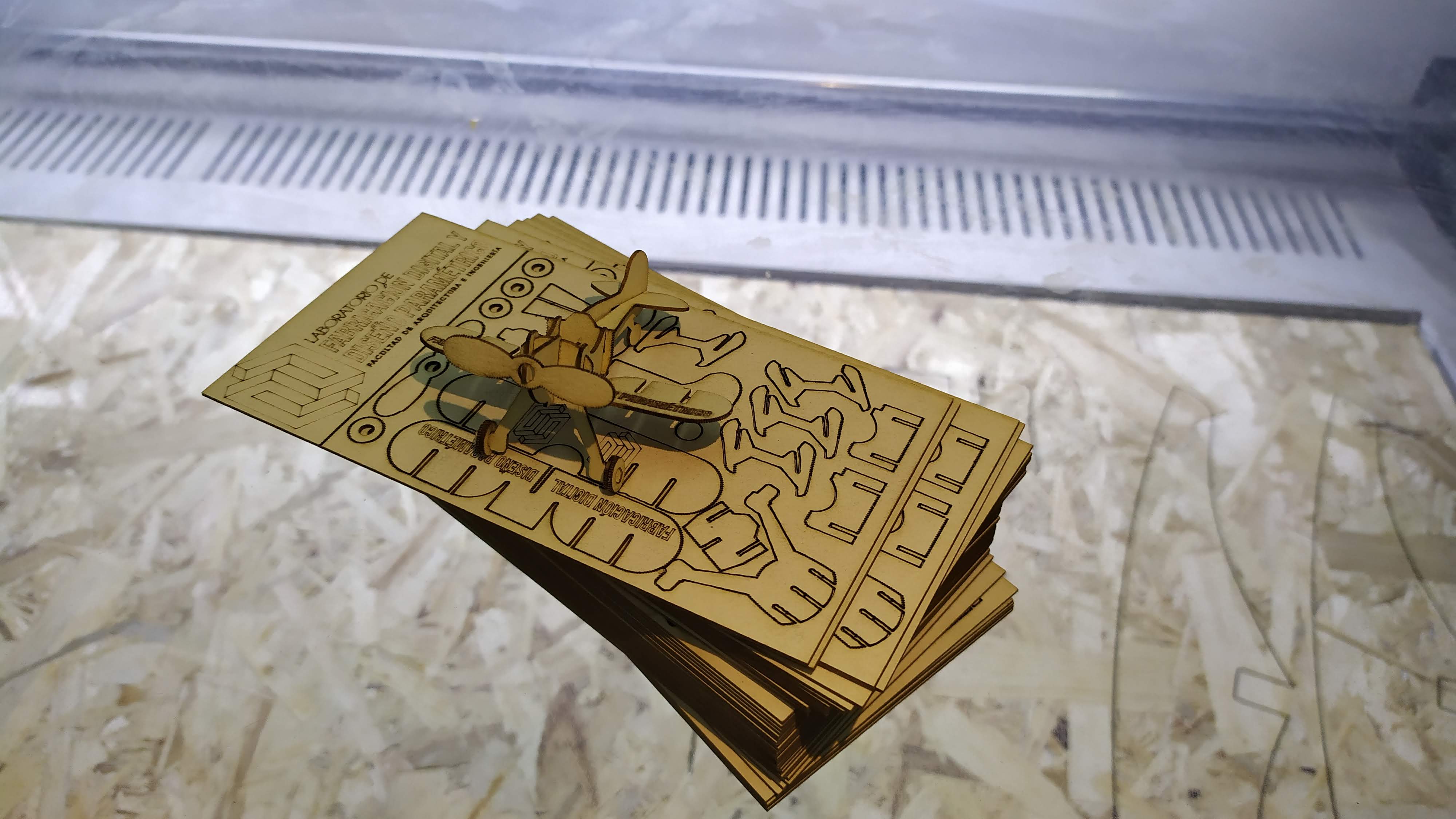

5. Electronics production

Currently in the laboratory we do not have a router to manufacture electronic devices. In order to make and manufacture the boards we resort to using a transfer paper that is applied on the single layer PCB and protects the circuit paths before giving it a ferric chloride wash.

Steps:

- We take as a reference which electronics element we want to use, in our case an ESP32 , with integrated Wi-Fi and dual-mode Bluetooth technology.

- We used an electronics prototyping board to understand what were the wires we needed to join.

- The mechanism is focused on light detection and depending on the intensity the device moves by means of a servomotor.

- In the PCB Wizard program the design was created based on the measurements of the PCB board available.

- It is printed on a transfer paper (the printing or design of the circuit is upside down to be able to paste it and that it is on the right side)

- Glue it to the board and use heat for about 10 minutes to transfer the ink to the board.

- Remove the excess paper and wash it.

- Dip for the necessary time in ferric chloride until the excess copper is removed.

- A motortool is used to open the perforations to place the ESP32

When it comes to understanding the colors and functions of the resistor, it is a little difficult for me because I have moderate color blindness.

was that the right color? we'll never know.