brainstorming session

Objectives

Group Assignment

1)Design a machine that includes mechanism+actuation+automation.

2)Build the mechanical parts and operate it manually.

3)Document the group project and your individual contribution.

4)Actuate and automate your machine.

brainstorming session

Though we had many discussions around assignment, and as recommended by instructors, we selected CNC

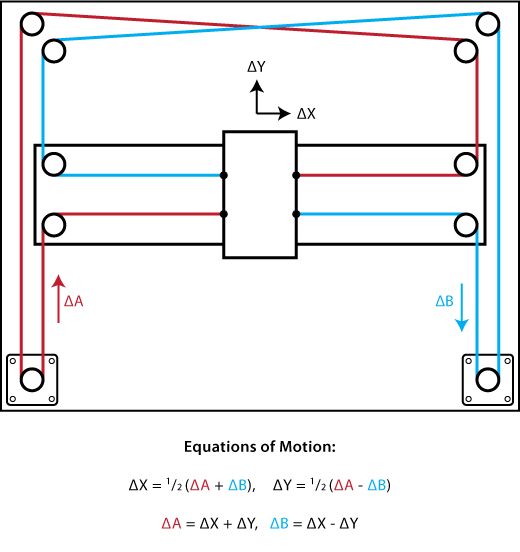

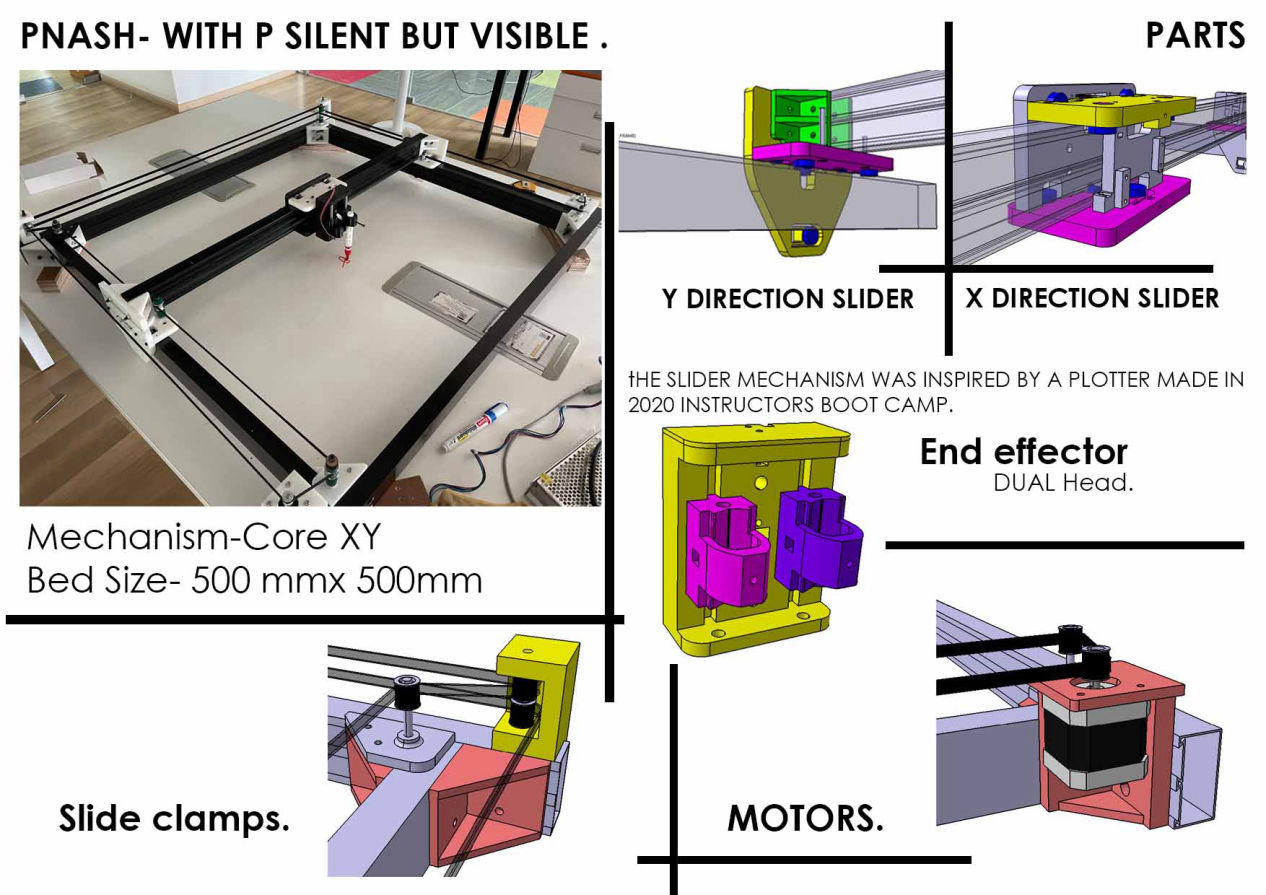

plotter as our main machine to be designed We selected core xy as the main mechanism.

Talking about Core XY, First of all Thank you to Ilan E. Moyer for the great documentation from which we could learn a lot. Please refer to this documentation for the detail theory

Then we divided the team into five groups:

1. Mechanical Design

2. Fabrication

3. Electronics and programming

4. Material and management

5. Documentation

I was assigned to in Design(helping Pallab with iterationing CAD),testing parts and fabrication.

We Went through various process from designing, fabricating, testing, assembly, and most importantly prototyping a lot of mini parts as per designs.

As a team we first discussed will all about how to make it. For the driving system, timing belts with stepper motor was confirmed.

For that we got out specification of our machine size wise

Machine size: 1110mm(x) * 1060mm(y) * 175mm(z)

Bed size: 766mm(x) * 756mm(y) (Updated after designing)

Please follow this link for the group website.

PINASH

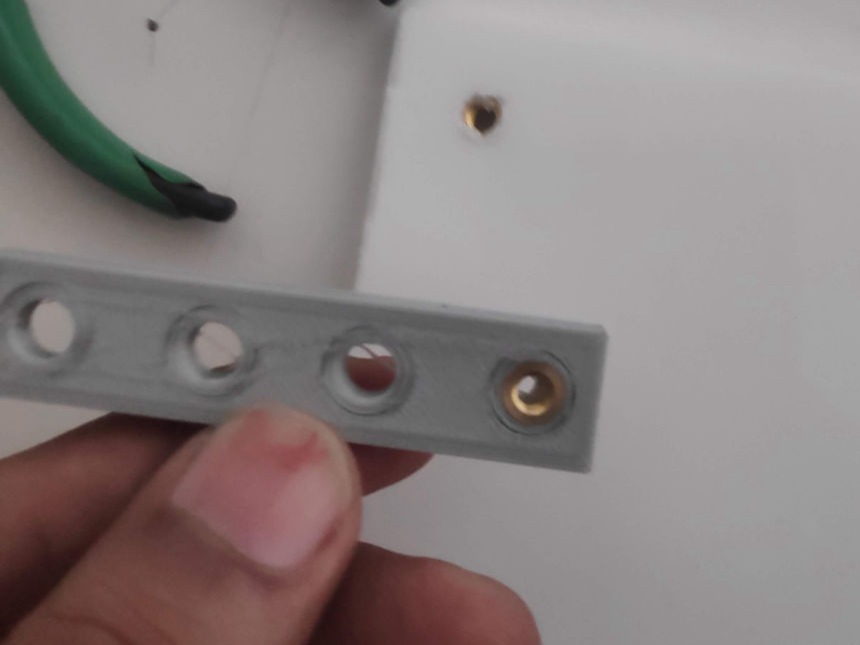

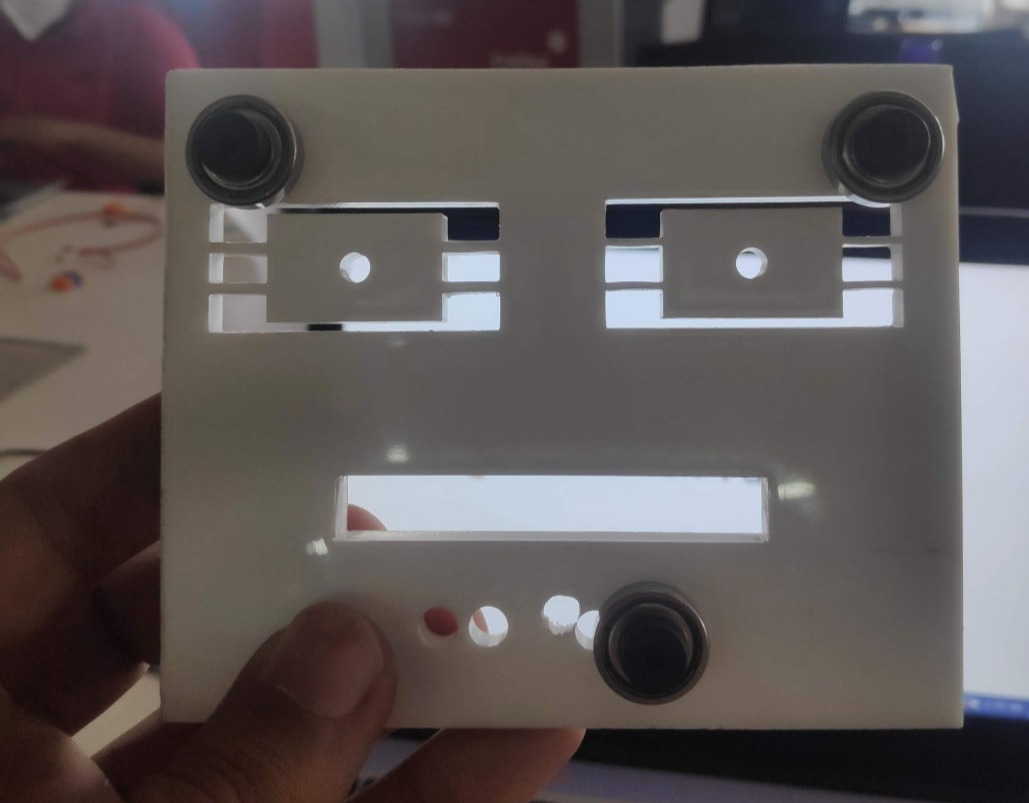

Testing inserts in 3d printed pat and dimensions.

Inserts dimentions

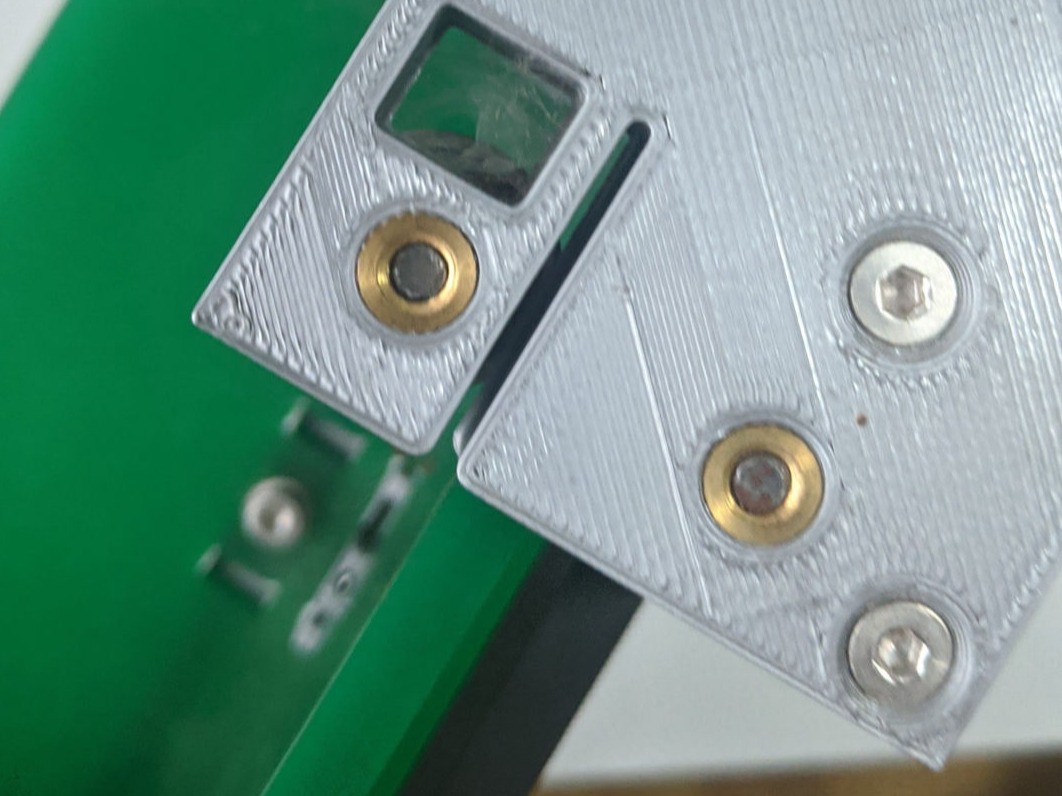

fabricated and tested flex distance in flexure.

Tested inserts on laser cut flexures

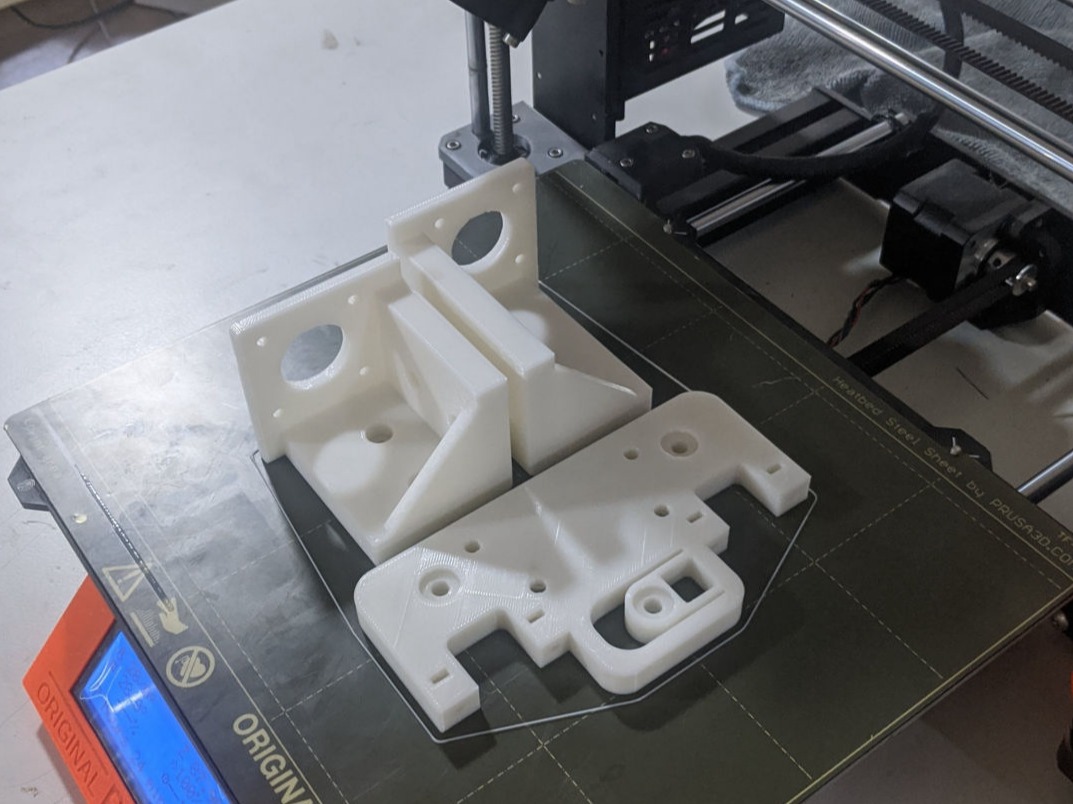

3d printing gantry parts

Flexure testing

Assembling the Parts.

Topology Optimization in Autodesk Fusion 360 Tutorial.

Why Shape Optimization?

>>Saves lot of 3D printing material.

>>Faster 3D printing.

>>Cool looking ; )

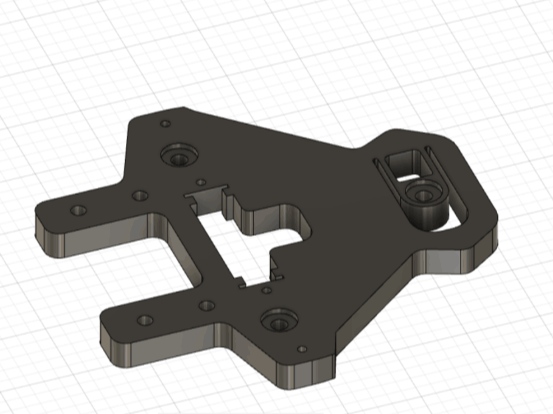

After Shape Optimization.

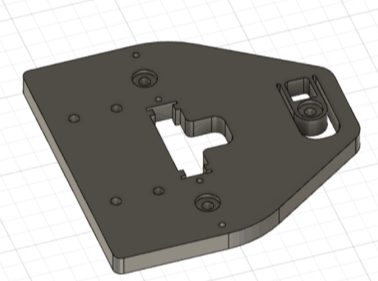

Before Shape Optimization.

Created with Mobirise - More here