Cast Product 101

Mixing and Casting

Objectives

Individual Assignment

1)Design a mold around the stock and tooling that you'll be using,

mill it (rough cut + (at least) three-axis finish cut),

and use it to cast parts.

Group Assignment

1)Review the safety data sheets for each of your molding and casting materials,

then make and compare test casts with each of them.

It’s always important to first read the datasheet to make sure you take the right safety preconditions. In the datasheets you can find the ‘Hazardous materials identification system’ (HMIS), this is a system that checks materials and gives information on four criteria: Health, Flammability, physical hazard and personal protection. More detailed information can found on the Wikipedia page HMIS-system.

SORTA-Clear 37 is a premium water white translucent silicone rubbers (platinum catalyst) which cure at room temperature with negligible shrinkage. These rubbers feature high tensile and tear strength. They offer the convenience of a 1A:1B by volume mix ratio. They are ideal for making prototype, jewelry or other molds of any configuration where model visibility is

important (i.e. extracting a model from the mold via cutting). Materials such as urethane, epoxy or polyester resins can then be cast into these silicone without application of a release agent. Other materials such as wax and low melt metal alloys can also be cast into the mold made out from this rubber. These can be pigmented with SILC Pig™ silicone pigments. They are also FOOD SAFE and can be used for culinary applications including casting chocolate and other confections.

You can download the technical data and process to use SortA clear 37 from this link. Please follow the safety regulations according to the safety datasheet in this link.

Since the SortA-Clear 37 which we had been using was old, there were bubbles already in the rubber before mixing. First we decided to save time for understanding the process safety and the quality of the mold so used the old milled was for molding.

Main thing first, since the mix has a pot life of 25 min, keep everything ready on the table so that the process goes uninterrupted, wear your safety gears like gloves, masks, and glasses.

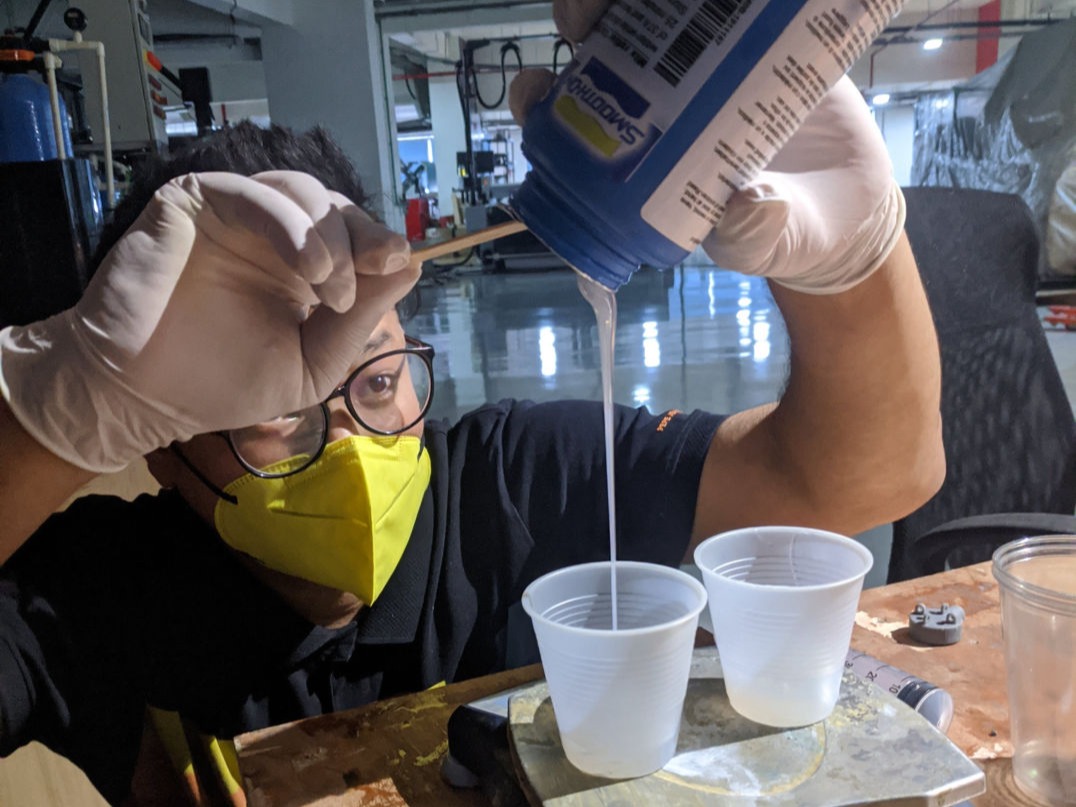

First trying the SortA-Clear 37, it had the ratio of 1:1 by volume and also 1:1 by weight for part A : Part B. There are 3 ways three ways to mix Part A and Part B.

1. Pour a volume of Part A and same volume of Part B and mix it

2. Pour a weight of Part A and pour same weight of Part B

In our case, we used the second one, mix by weight, but took reference of amount of material by volume. To estimate the amount we should be mixing, the volume of the mix has to be known so as to prepare it so take a cup, translucent or transparent, pour water into the milled part , pour the water into the cup, mark the total volume and mark half the volume. Now put the cup on the weighing scale set the weight to zero with the cup (In case you cant set zero the weight with cut, please consider the weight of the cup and use the difference for calculation). Pour Part A up till half mark we made on the cup or a little bit more for being safe of amount of mix. Weigh it and add Part B of same weight.

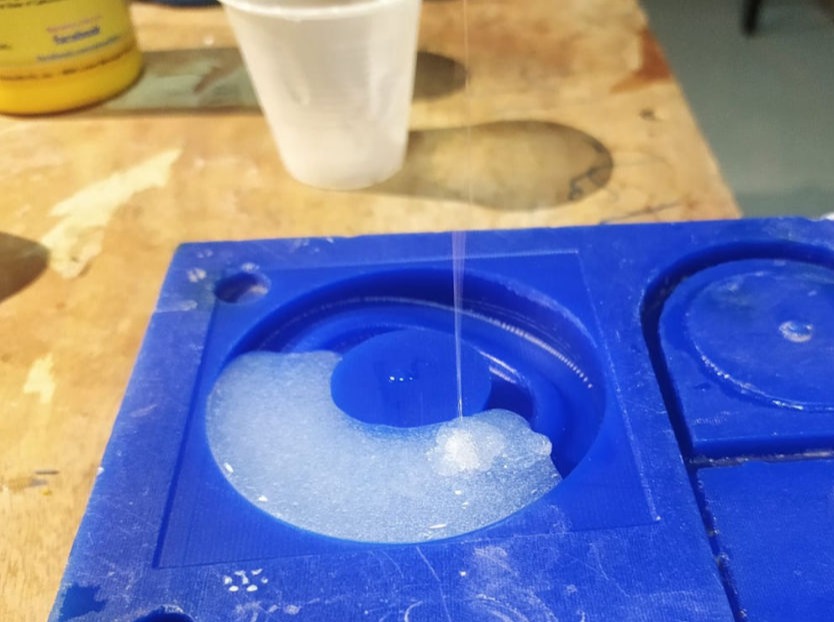

Then mix it with only horizontal strokes, not vertical strokes or it might add the air bubbles into the mix. Less the air bubble, better your mold will be.slow mix has to be done so that the air bubble do not form. You might use vacuum chamber to remove the air bubbles if you have it in your lab. We did not have it in our lab so we were unable to use it. If the bubble comes in the surface where the material is cased, you might have defect in your mold and the part which will be cast out of that mold. You can follow this link to know other ways to eliminate bubbles. Remember that the pot life of the mix is just 25 minute of do not let the mix stay for more than that. It might be different for your material which should be mentioned in the datasheet.

Cast Product 101

Mixing and Casting

Each Pringle is designed to take the geometry of a hyperbolic paraboloid.Perbolic paraboloid is the point where the maximum and the minimum of the two principal curvatures meet each other at a zero point. This is known as the saddle point or the minimax point.Hyperbolic paraboloid's intersecting double curvature prevents a line of stress from forming, which doesn't encourage a crack to naturally propagate. That's why Pringles have that extra crunch in them when you either bite a piece off or when you put a whole Pringle in your mouth.

I want to have my own cast Hyperbolic Paraboloid rings.Creating mold that can open up to loop around the previous link. The mold has to be small enough to fit through the previous element of the chain.The curvature of the surface is symmetrical, the two halves of the mold could be identical, meaning I would only have to machine one half of the mold from wax and could cast silicone off of that cavity twice.

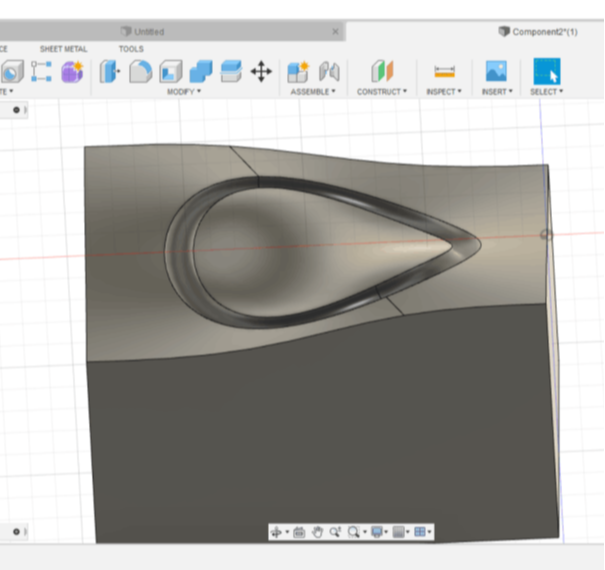

Circle Sweeping on a circular path(which is projected over hyperbolic Paraboloid Plane)in Fusion 360.

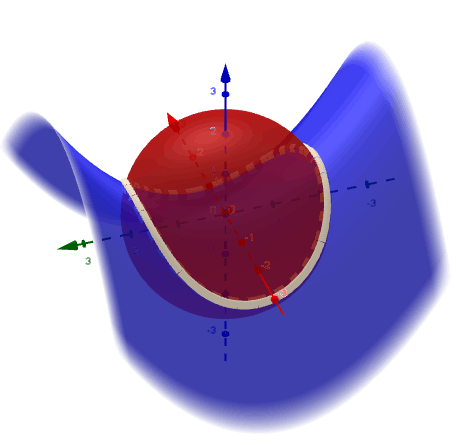

Curve of intersection of a sphere and hyperbolic paraboloid.

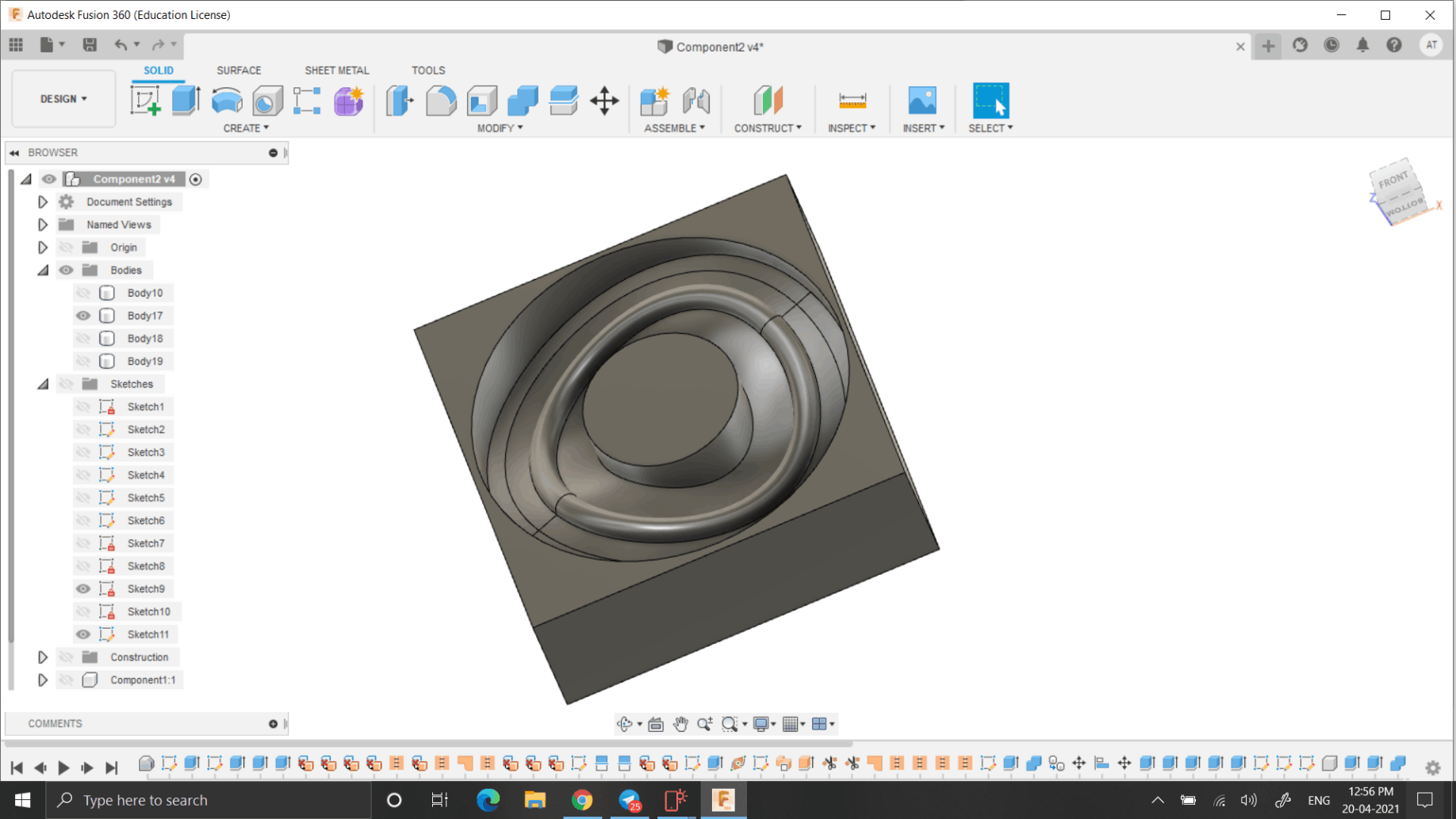

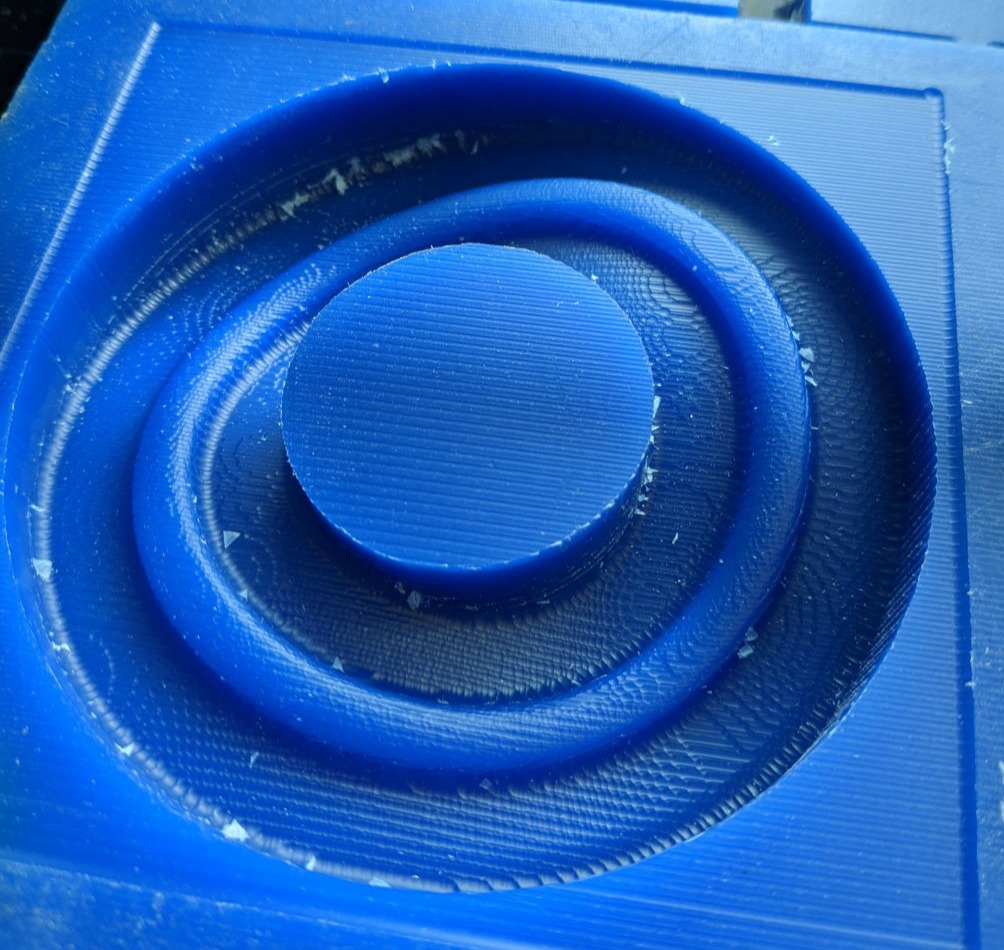

Completed Design Of The Wax Mold to create the original mold.

For milling process the I am using "1/8 inch" ball end 4 flute bit and I had attached it to the Roland Molling machine as usual.then wax block and attach a double sided tape to the back side. Then you need to stick the wax block to the milling machine bed

Rough Cut Vs Smooth Cut

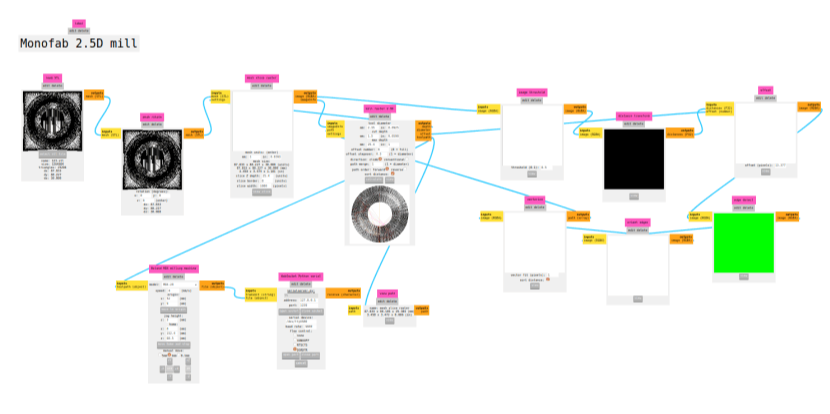

Using FabMods to Crete tool-path

Final Output.

First for the rough cut, 3mm Flat End mill was set on the tool head. Open mods, go to programs and click on 2.5D mill inside Mdx-20.

(Imp: Do not use milling tool with more flutes on wax. If more fluted tool is used, there might be a problem for material removal and may start melting of the wax and finally stopping the rotation of the bit. This might also break the bit if thin bit is used.

Then the X, Y and Z axis. Load the STL file in the mods. Make sure that the tool size is correct. Check the feed, speed, and hit calculate. For me the speed was 10mm/s, feed was 1.5mm. You can see the toolpath in the preview and confirm the shape you are making. after everything is OK send the file which should start the milling operation.

Once we have milled the wax mold, we have to calculate the volume of silicone that we are going to need. To do this by reviewing documentation from other students, there are two options. Use rice or use water.

. Sorta Clear 37 has Shore 37A hardness and features high tensile and tear strength. This product also offers the convenience of a 1A:1B by volume mix ratio.

I had opted Smooth-On Sorta Clear 37 Silicon mold rubber for making the mold

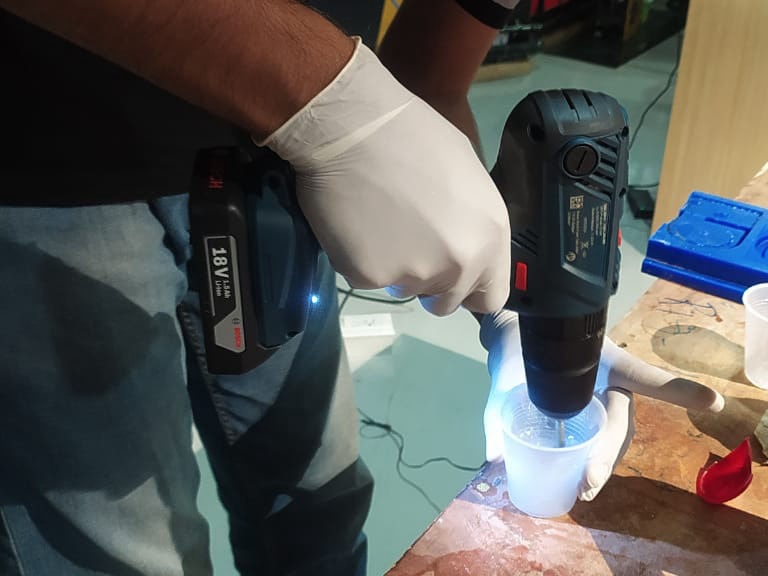

You can also mix using a driller in a low rpm circular end so that it won't capture air bubbles.

Mixing Part A and Part B in Equal Volume.

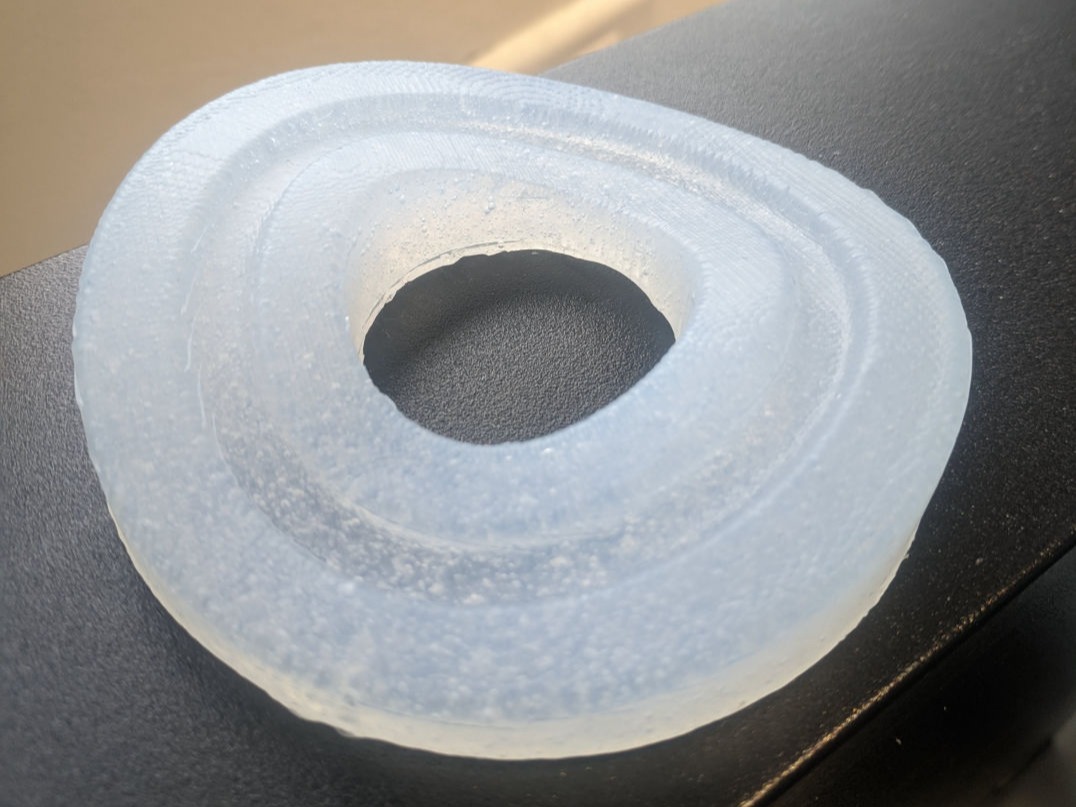

Final silicone mold. And I Also created the same again to get the other half mold.

The last step is to pour the mix into the mold and leave it for curing. This mix normally takes 6 hours to get cured and you can check intermittently to ensure that the mold get solidified.

For casting I had used Smooth-On SMOOTH CAST 305 which is bright white liquid plastic. They are are ultra-low viscosity casting resins that yield castings that are bright white and virtually bubble free. Vacuum degassing is not necessary. They offer the convenience of a 1A:1B by volume or 100A:90B by weight mix ratio.

I used a injection syringe used to inject the cast mix.

I cut out acrylic for extra support for 2 part mold.

yeeayyeeee.

Opened the mold after curing its was only like 2 hours

For creating chain parts i just cut out the supports and mold and re-casted putting a cast product inside.

Re-casted

Cut out mold and kept the cast product inside

Repeattttttt.

successful.

Final product of cast chain

Website was designed with Mobirise