This assignment is about characterizing the 3D printer we have in our lab. The 3D printer is PRUSA i3 MK3 as shown in the image below.

Test parts

The test files are available in the class archive. We downloaded them and sliced them then printed them.

Results

Surface finish

We used layer height of 0.2 mm which resulted in a pretty smooth surface finish.

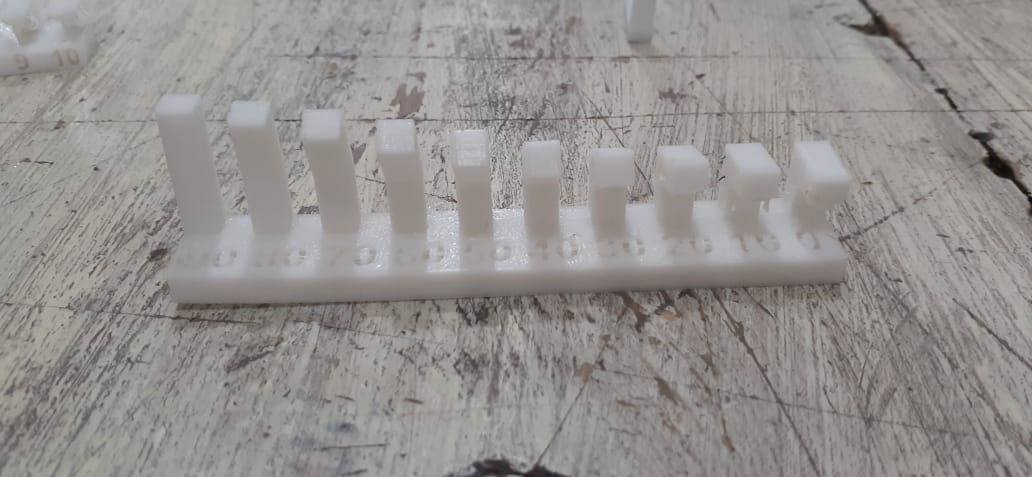

Overhang

Overhang taller than 8 mm were deformed which shows that the maximum overhang for our printer is 8 mm.

Bridging

Bridging result were very good for all lengthes and without any deformation.

angle

Angles less than 30 resulted in a deformed output which tells us that with angles lower than 30 we should use support.

wall thickness

We used 0.4 mm nozzle so we see that the minimum wall thickness is 0.4 mm.

Clearance

Clearnece of 0.2 is sufficient for free movement without jiggling.

Dimensions

Outer dimension is over with 0.08 mm meanwhile inner dimension is exact.