Fab Lab ECAE

CNC Machining with the Roland MDX-540

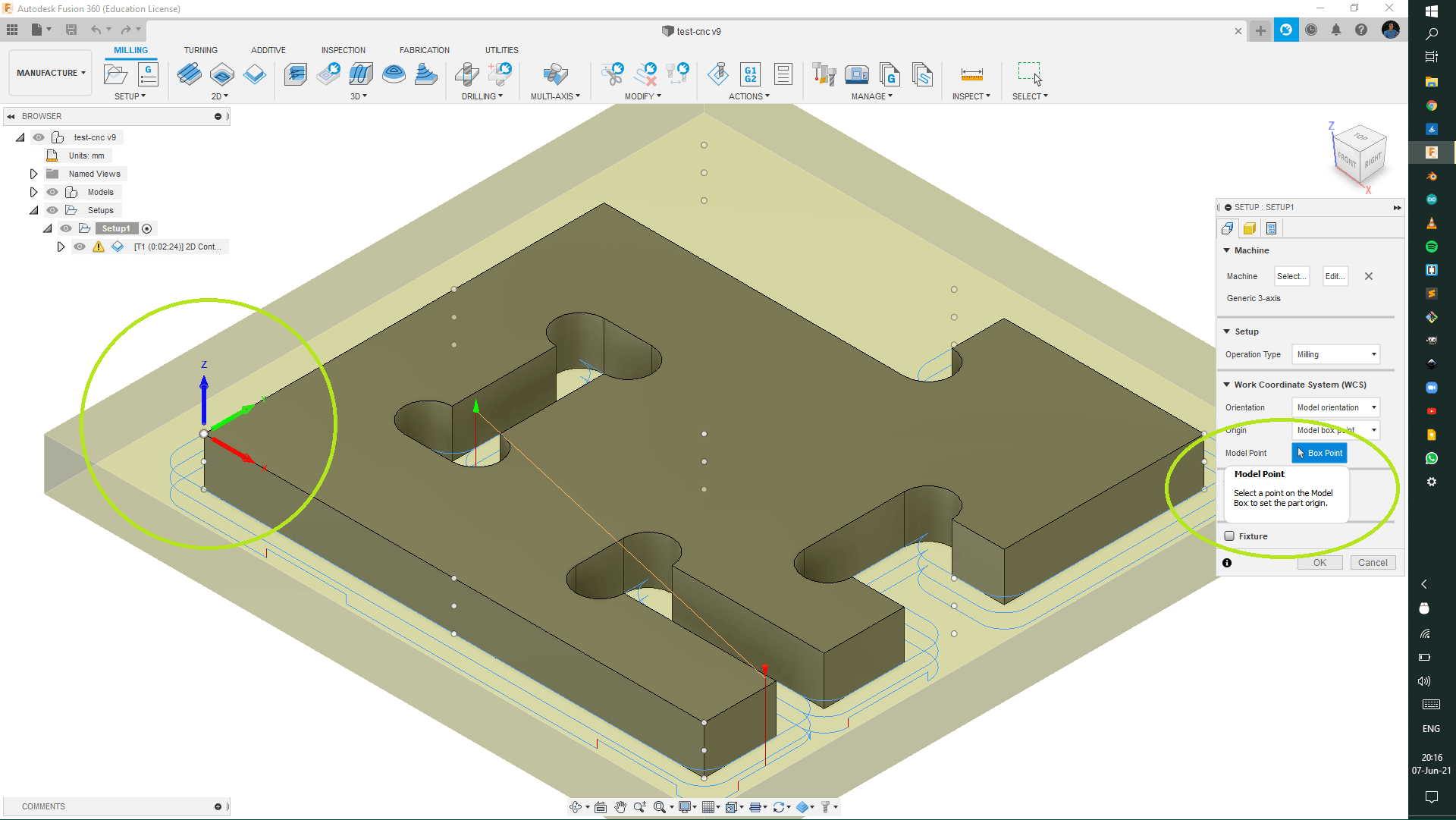

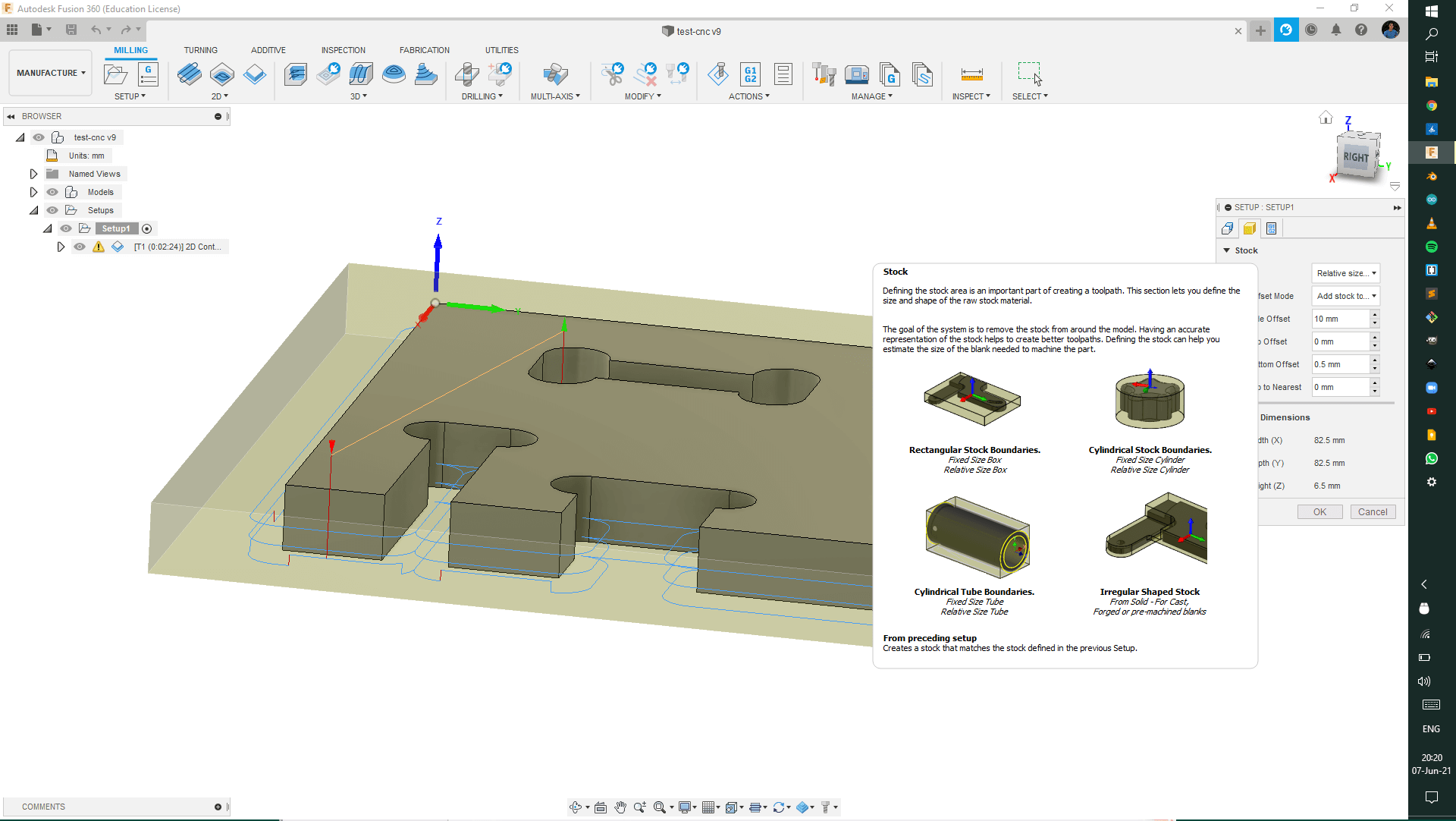

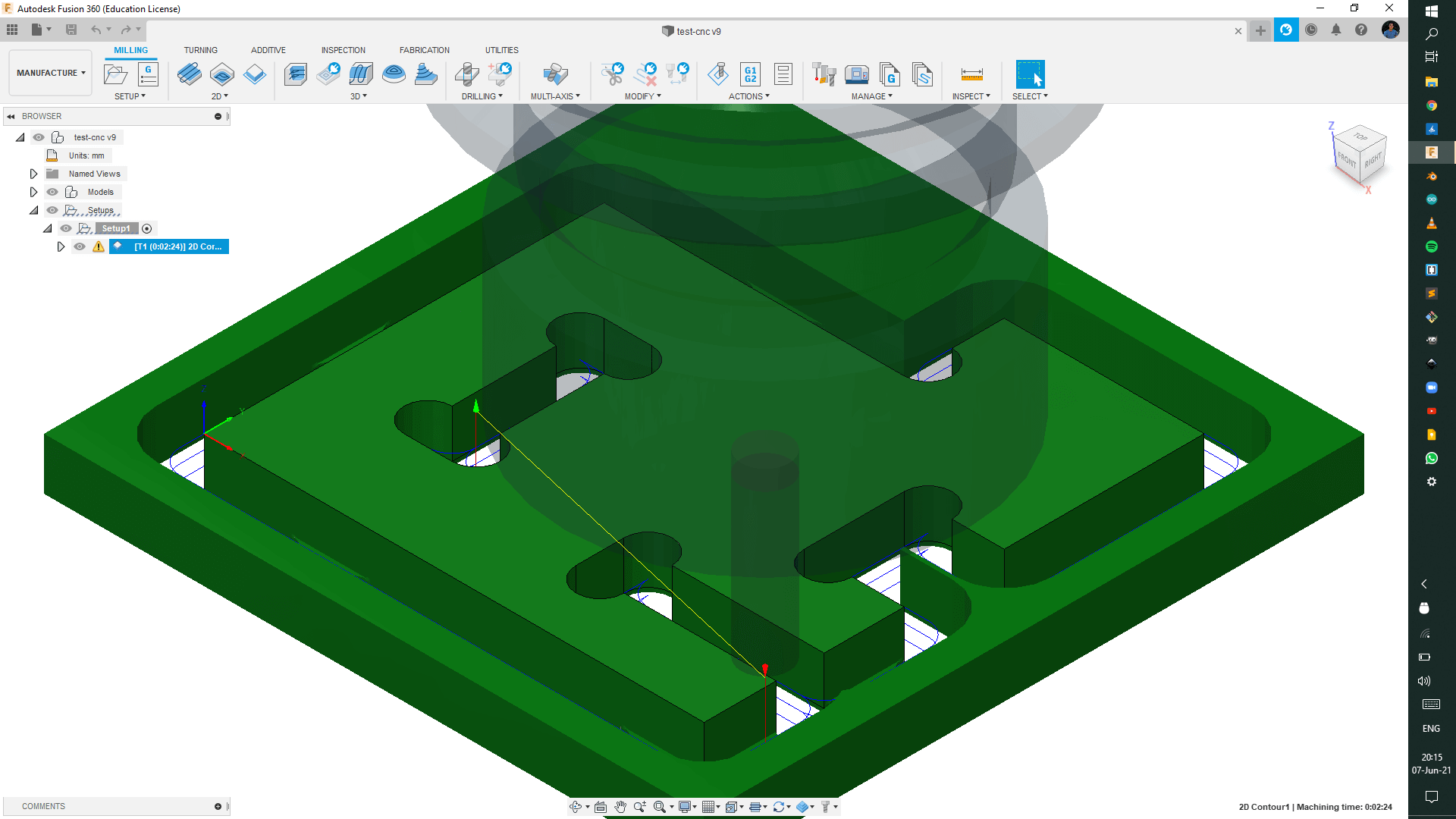

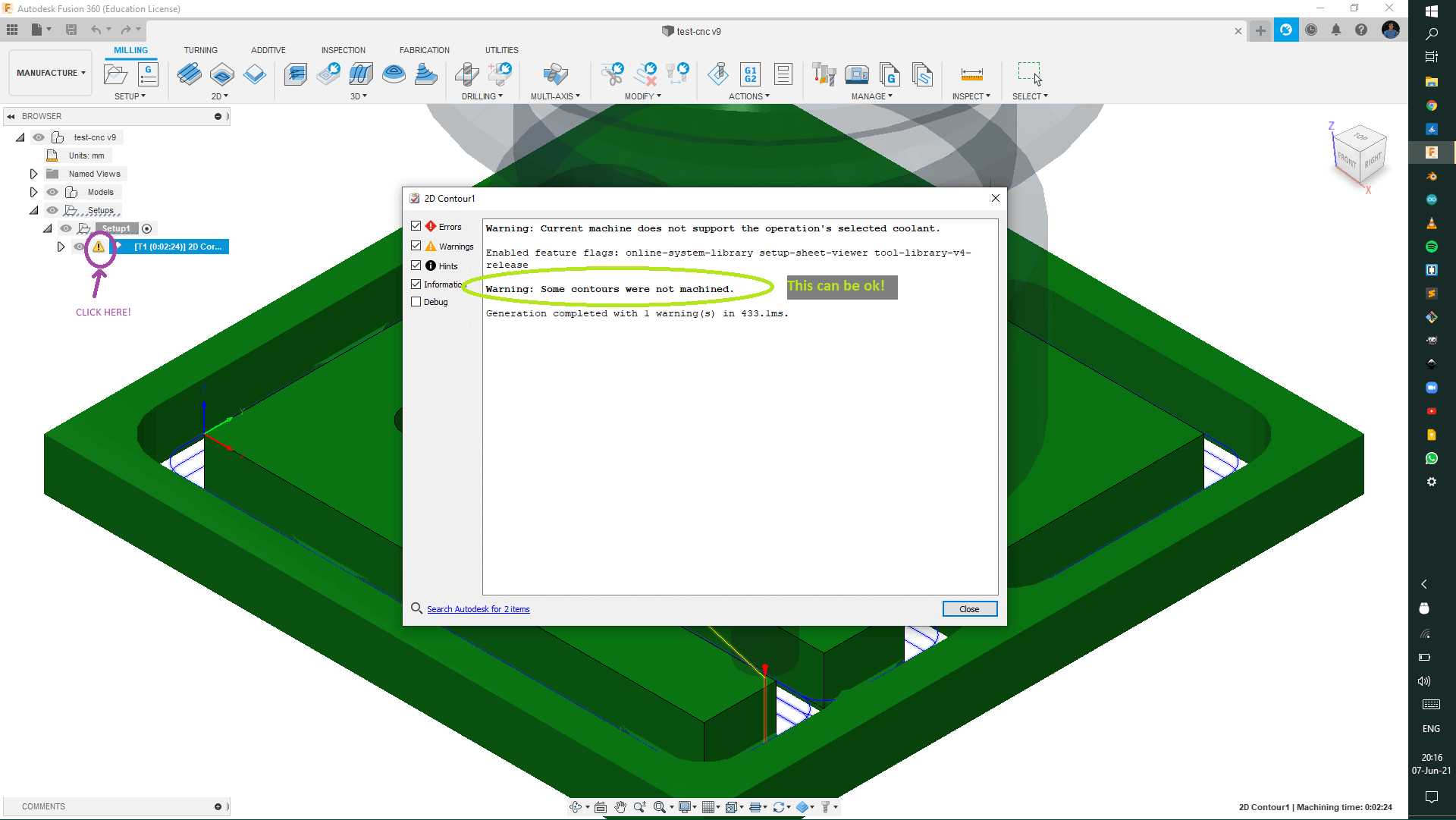

Using the MDX-540 in the labdo your lab's safety training test runout, alignment, speeds, feeds, materials, and toolpaths for your machine

tags: fusion 360 roland mdx-540 CAM

- This week's assignment will take two scheduled full days:

- + Day One - Go over safety proccedures, set up an example job, test feeds and speeds

- - And start designing our own job

- + Day Two - Set up our toolpaths and cut them on the MDX-540

╭─━━━━━━━━━━━━━━━━━━━━━━─╮

╰─━━━━━━━━━━━━━━━━━━━━━━─╯

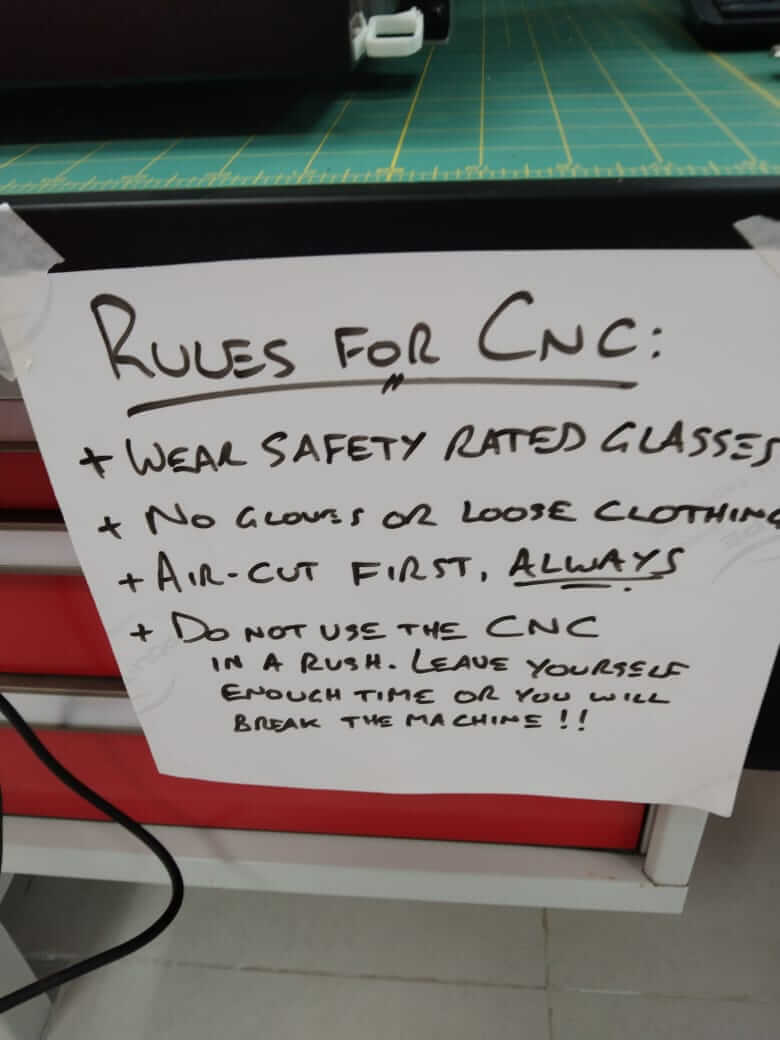

Rules for the CNC Machine

╭─━━━━━━━━━━━━━━━━━━━━━━─╮

1. When using a CNC machine, you must wear safety goggles to protect your eyes from any flying residue.

2. You must tie up your hair and you can’t wear loose clothing, gloves, jewelry (anything that can get caught in the machine).

3. Air-cut before starting a real cut in order to watch out for bolts (and just to see if your cut works properly).

4. Be patient and don’t rush when using the machine because rushing will only cause you more eventual problems.

4. Remember that if anything goes south, just press the big red button :)

╰─━━━━━━━━━━━━━━━━━━━━━━─╯

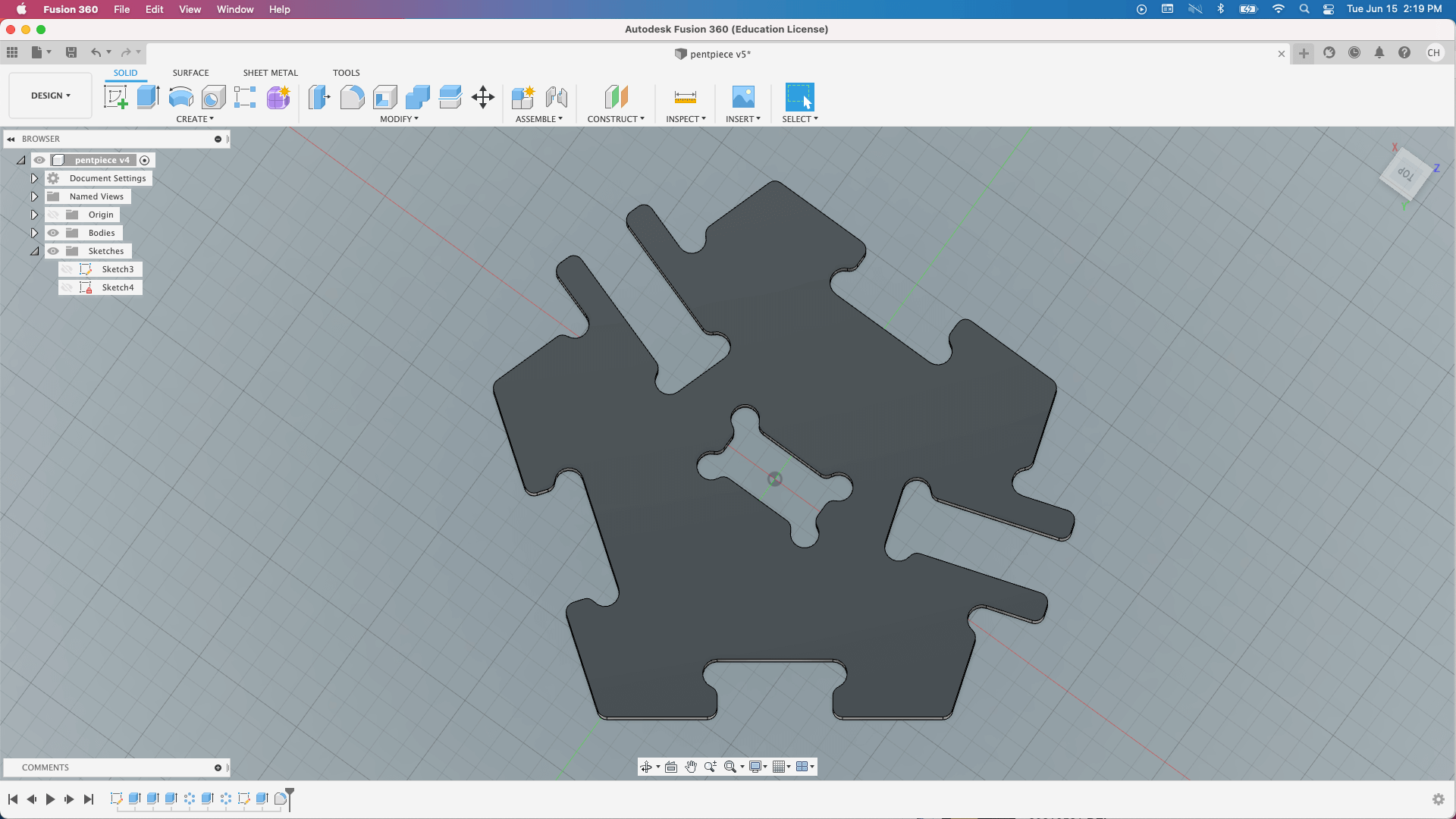

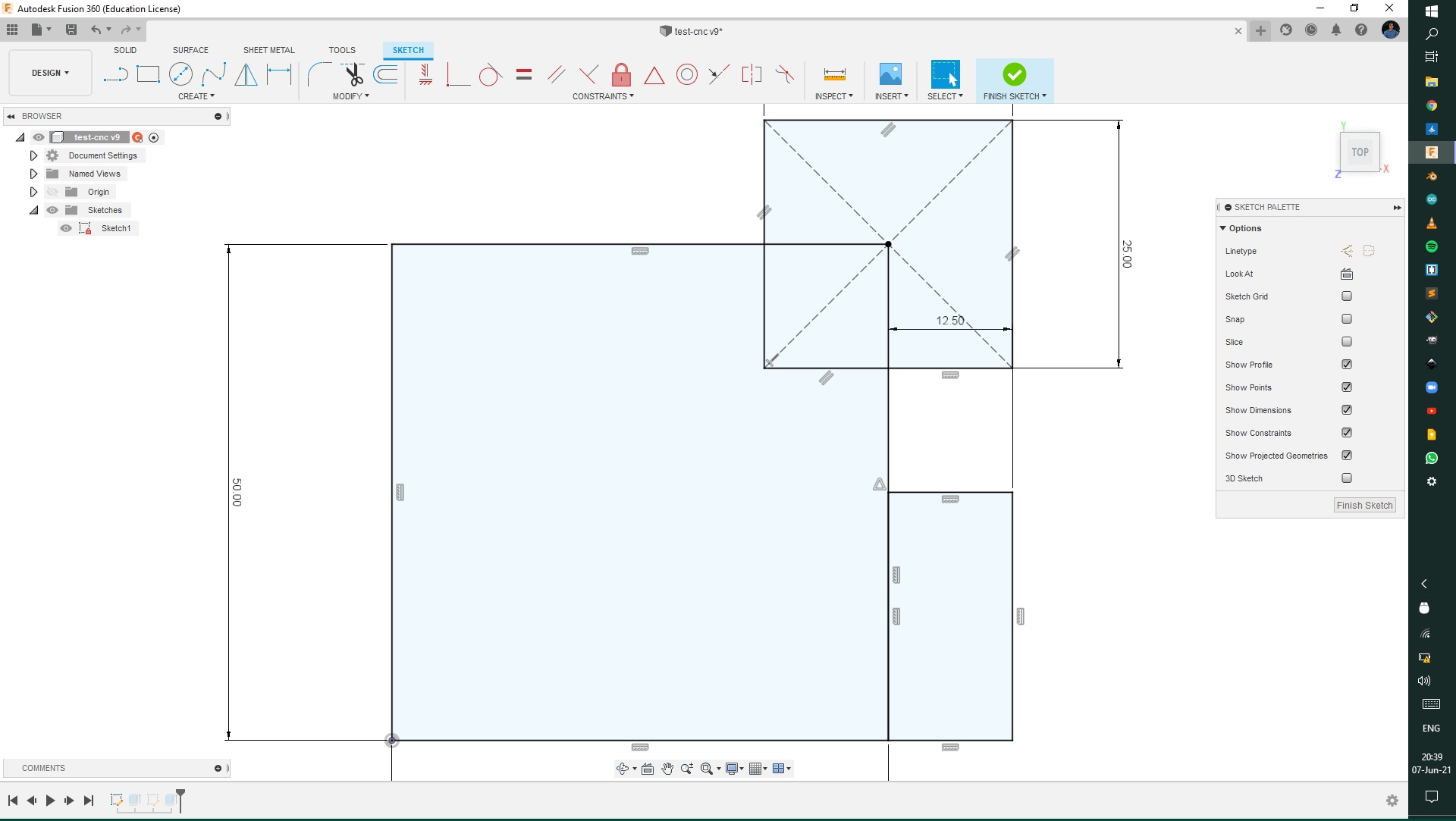

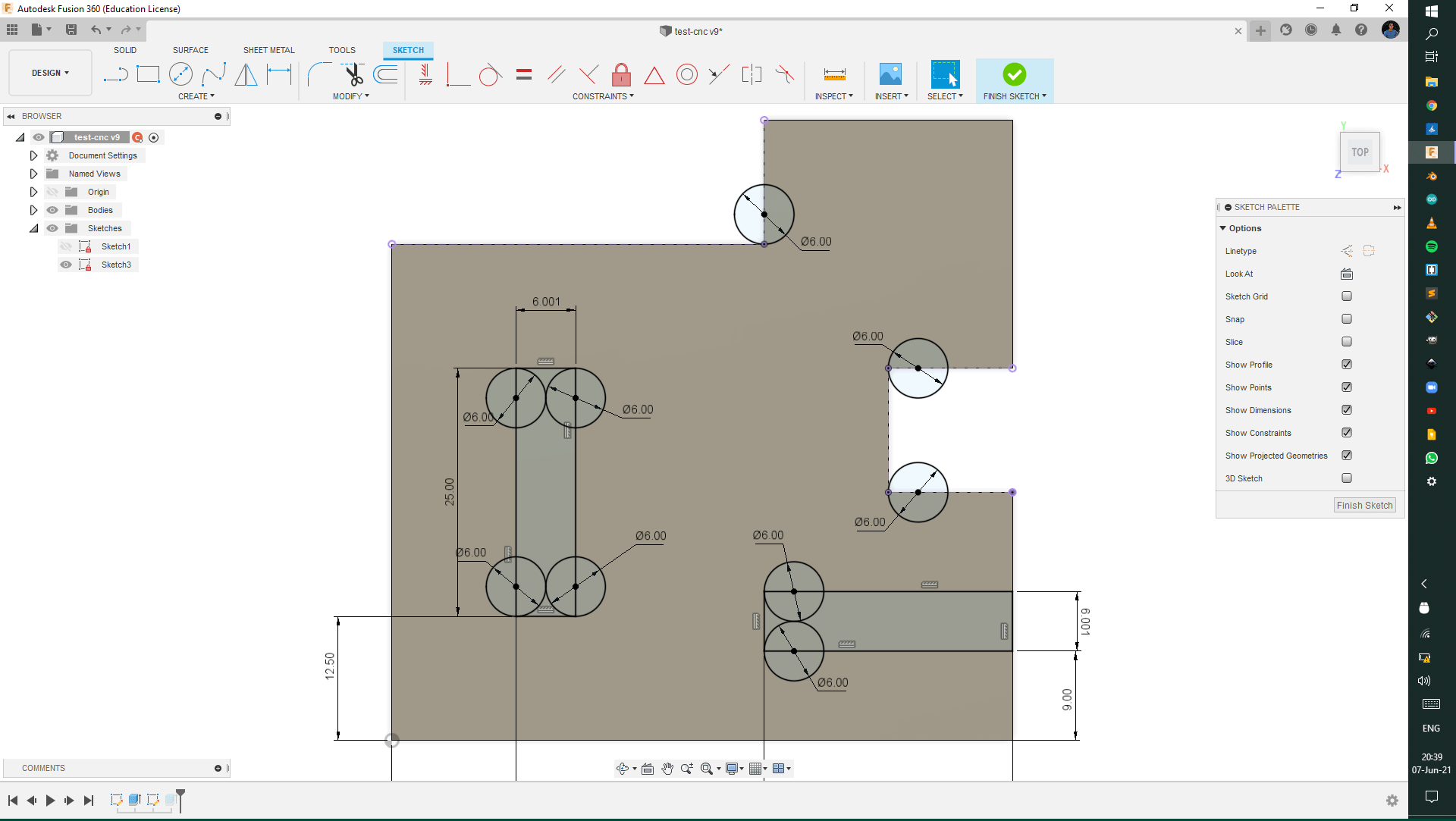

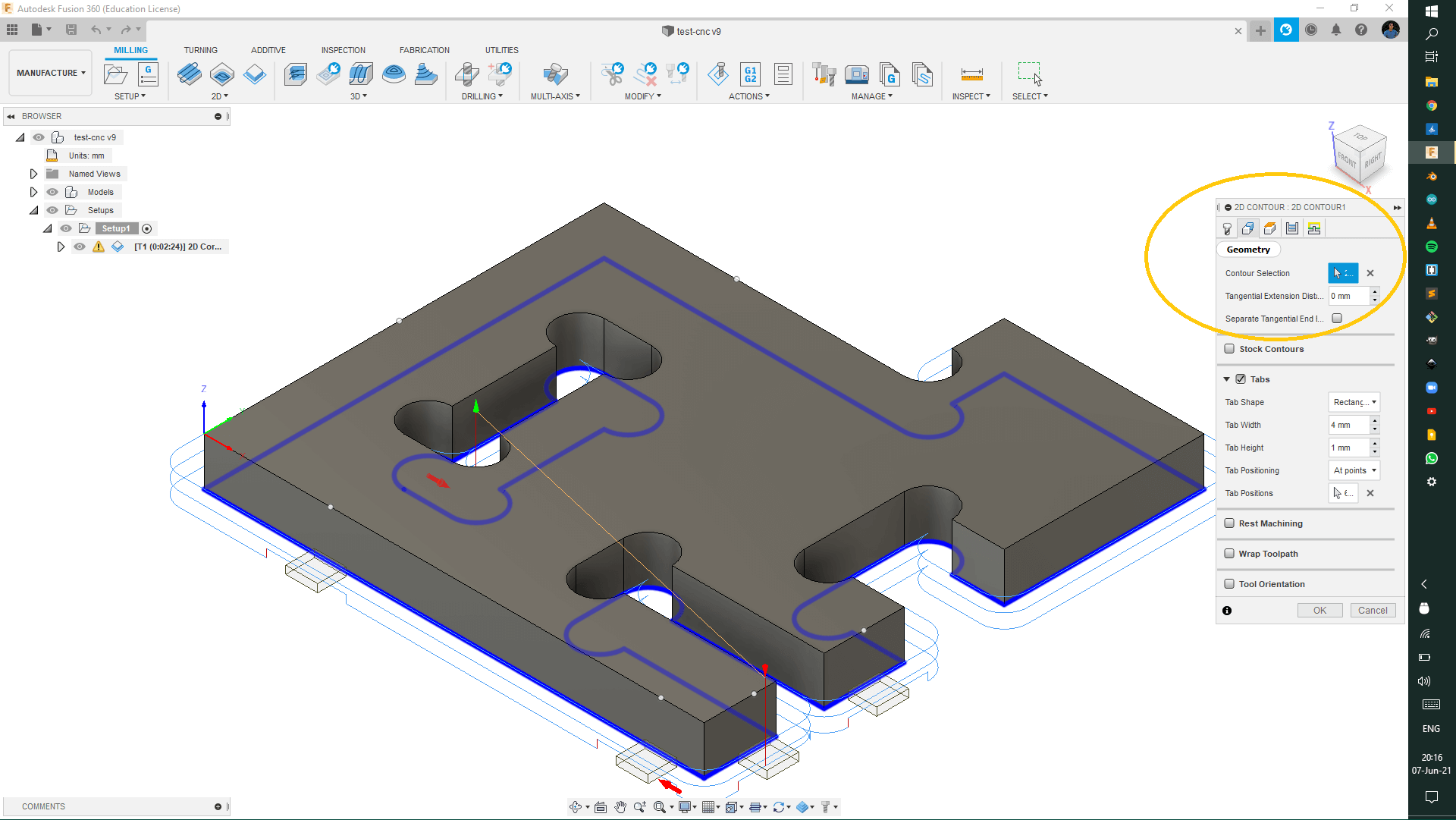

So, for this week we did a fit test to characterize the machine run out and kerf so then we can come up with a design that is a perfect fit with no issues. Thanks to my college cicely she designed this nice-looking press fit model that we can use for testing the machine.

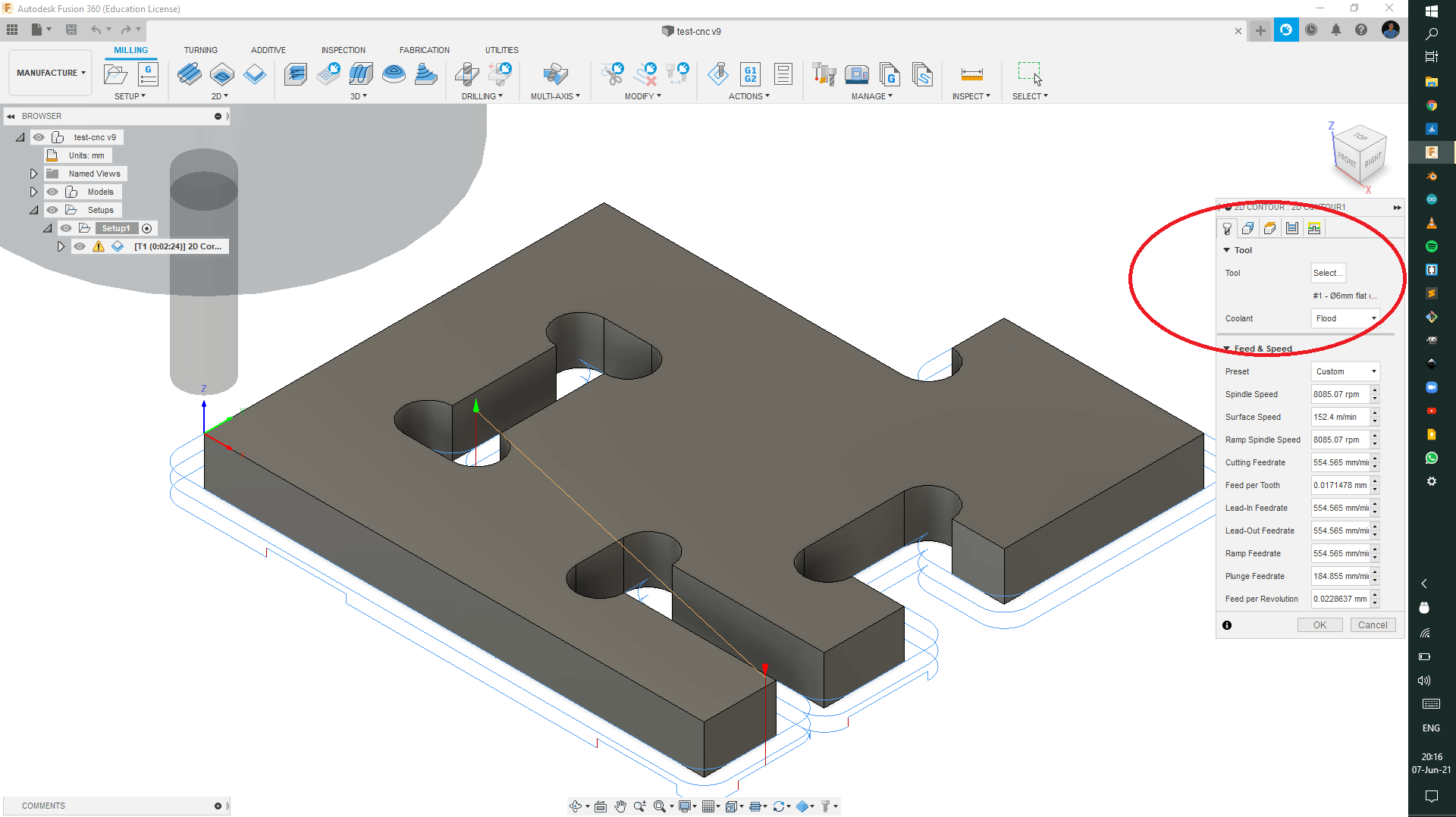

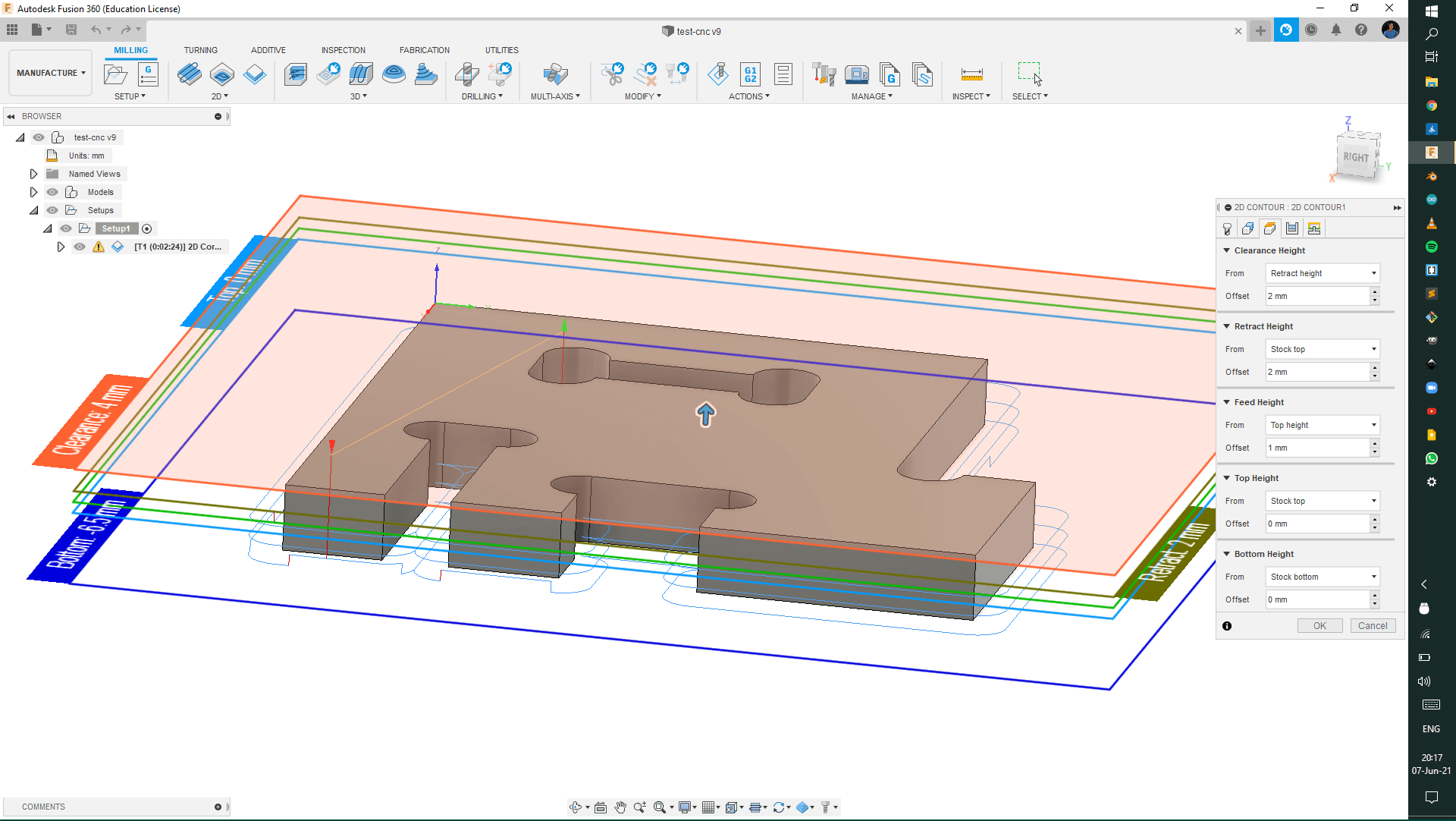

Spindle speed and federate:

The feed rate is the rate at which we move the mill bit across the material. The Spindle speed is basically determined by how fast the spindle turns the cutting tool. Depending on the material being cut, the feed rate and spindle speed will change. A typical rule of thumb is to pass the tool through the material as fast as possible without ruining the surface finish so basically we have to find out what would be the best spindle speed and federate in order to have a nice surface finish and of course without breaking the tool.we will be using roland MDX-540 as our CNC machine since our lab still do not have the big shopbot machine.

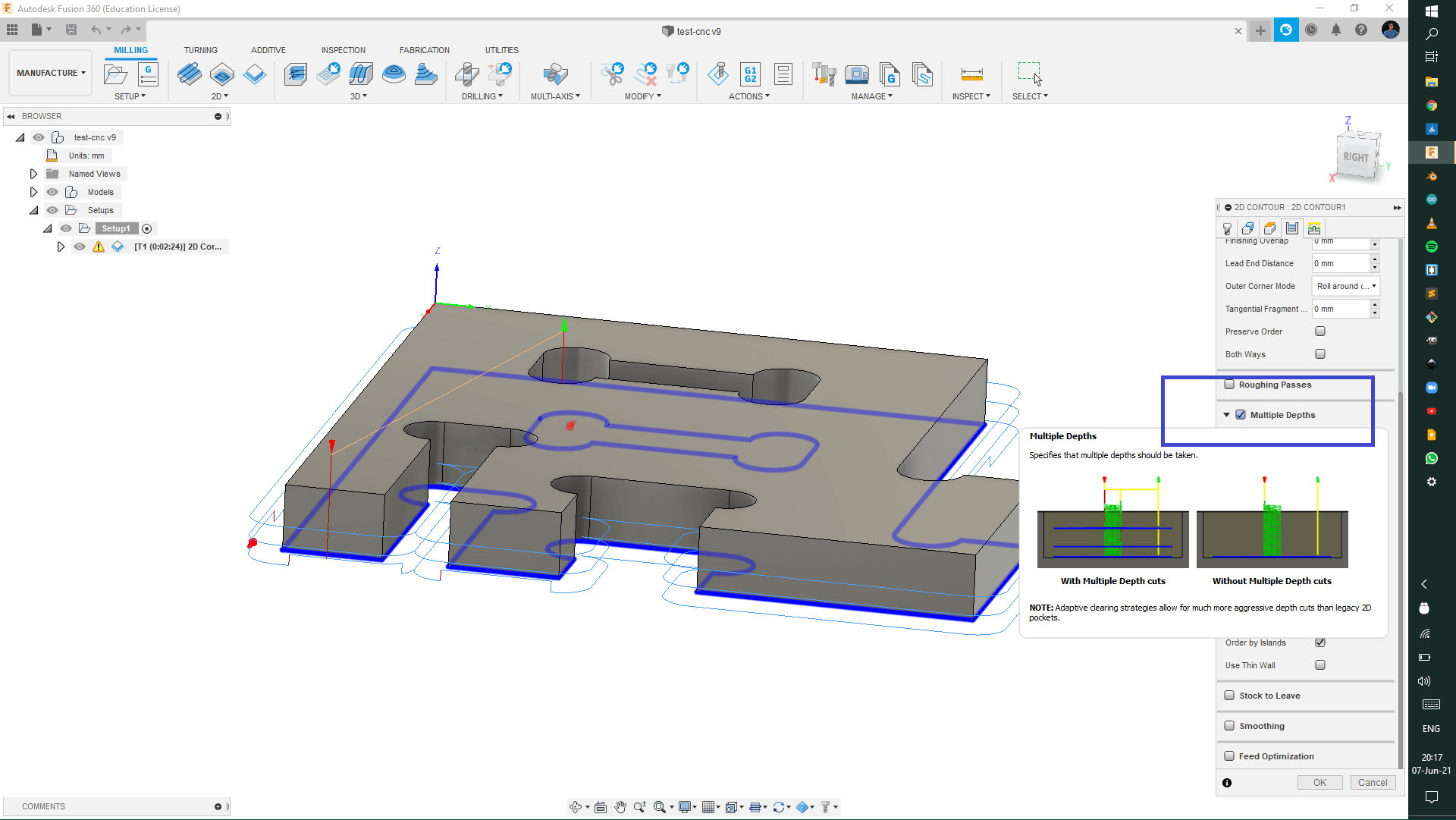

We did 3 samples with 3 different settings:

| Spindle Speed(rpm) | Feed Rate(mm/min) | Material Thickness | Tool Diameter | |

| sample 1 | 12000 | 1800 | 12.1 | 6mm |

| sample 2 | 12000 | 1000 | 12.1 | 6mm |

| sample 3 | 12000 | 800 | 12.1 | 6mm |

First sample:

The first sample is usually a failure in any kind of test so the moment the machine started cutting we noticed that federate speed is just too fast just by the sound of it so the job was not that accurate because in the last layer It started cutting through the tabs created to stabilize the object from moving however the surface finish was not so bad so we know that the spindle speed is good enough we just have to play with feed Rate to get the best result.

second sample:

we decreased the the feedrate 1200 to see if it makes any difference and it did improve the surface finish but it was a bit fast it cut the tabs that was created to stop the object from moving so that means we have to decreas the speed even more.

Third sample:

in third sample we decreased to 800 and the surface finish imporved drastically as showen in the picture so in the future we will be using these settings when cutting a 12 mm plastic sheets.

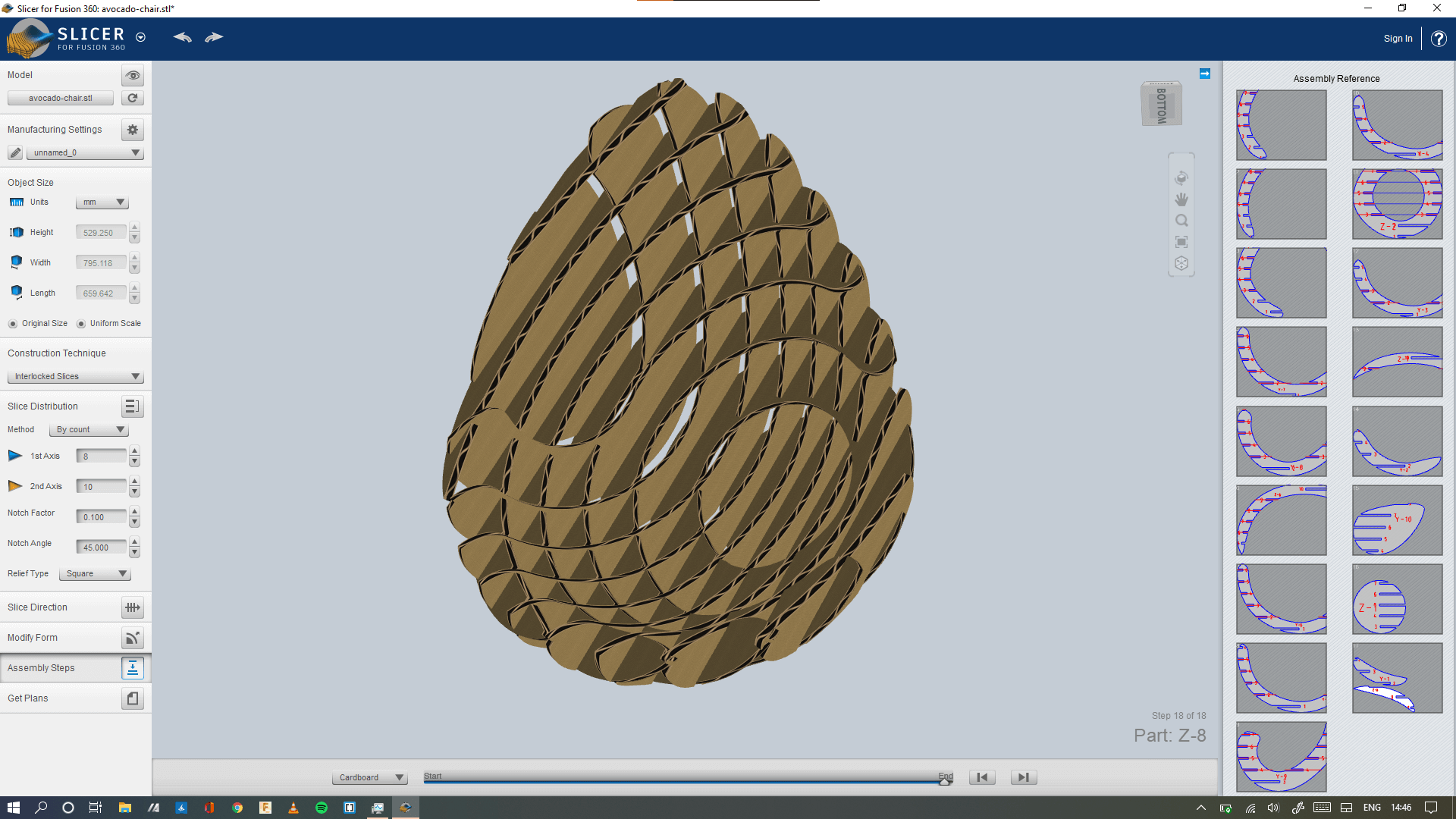

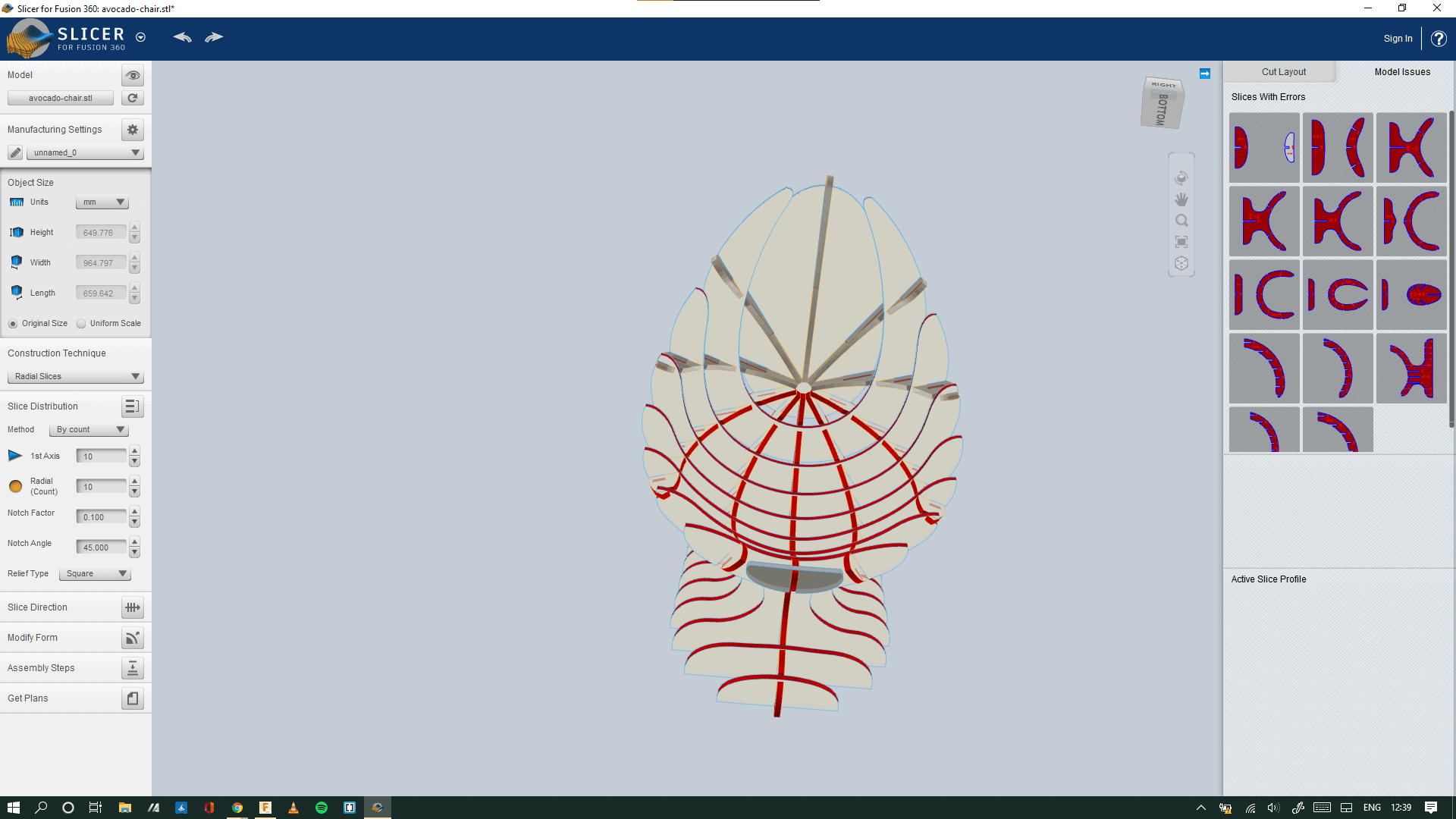

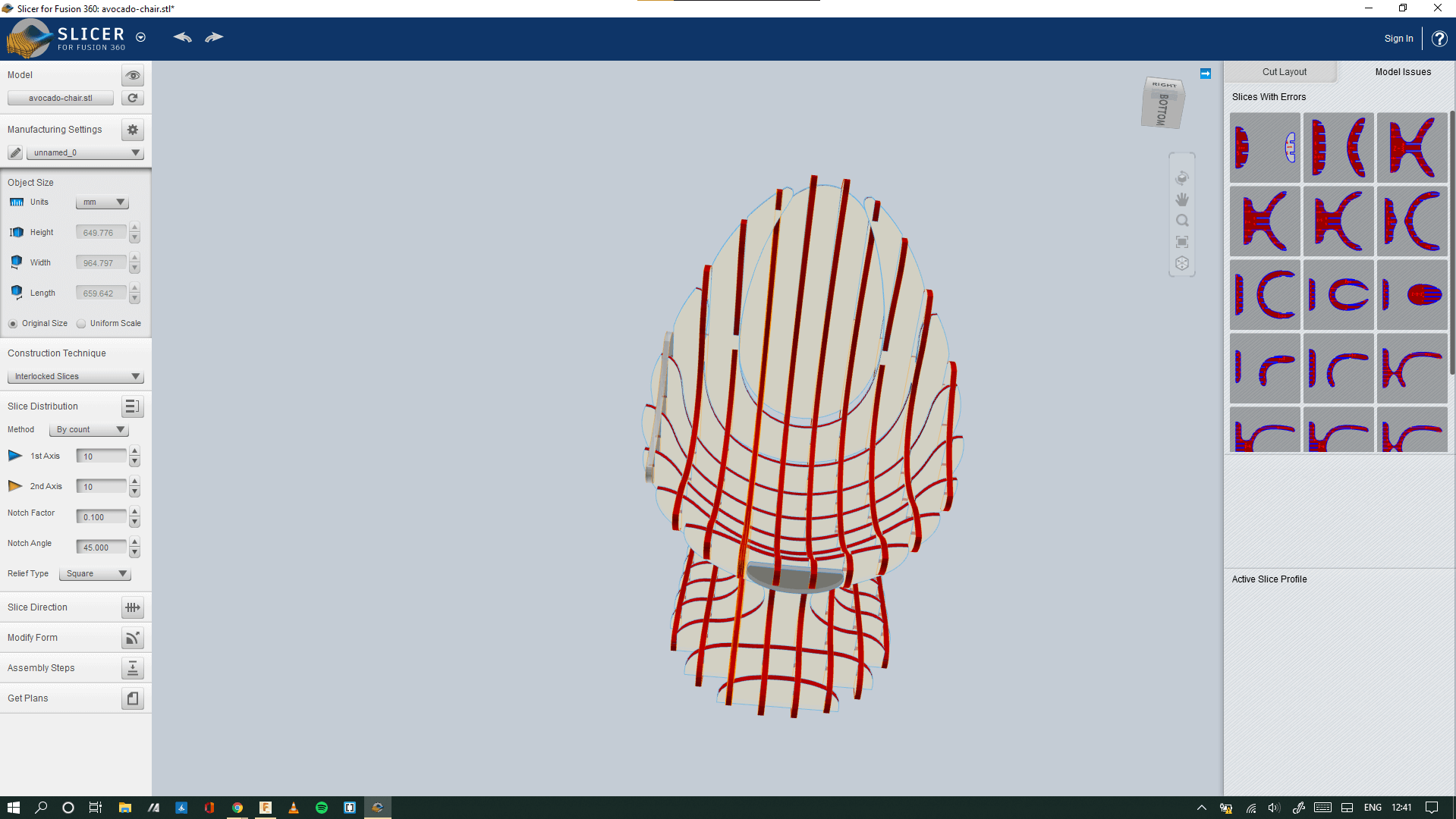

Extra - Slicer for Fusion 360

If we had a bigger machine we would be able to use this properly:

And here's an image of Cicely's egg-chair prototype coming together:

And here's an image of Cicely's egg-chair prototype coming together: