Nineteenth Assignment

Date

3 Jun 2020

Work Work Work !

The task in this assignment is answering multiple questions to track the project progress.

What tasks have been completed, and what tasks remain?

completed tasks:

completed tasks:

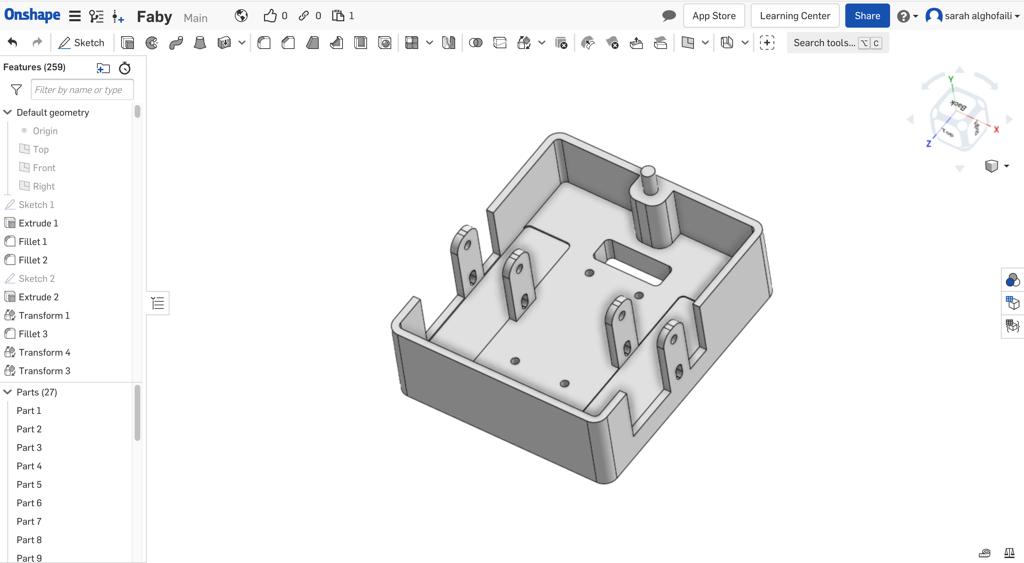

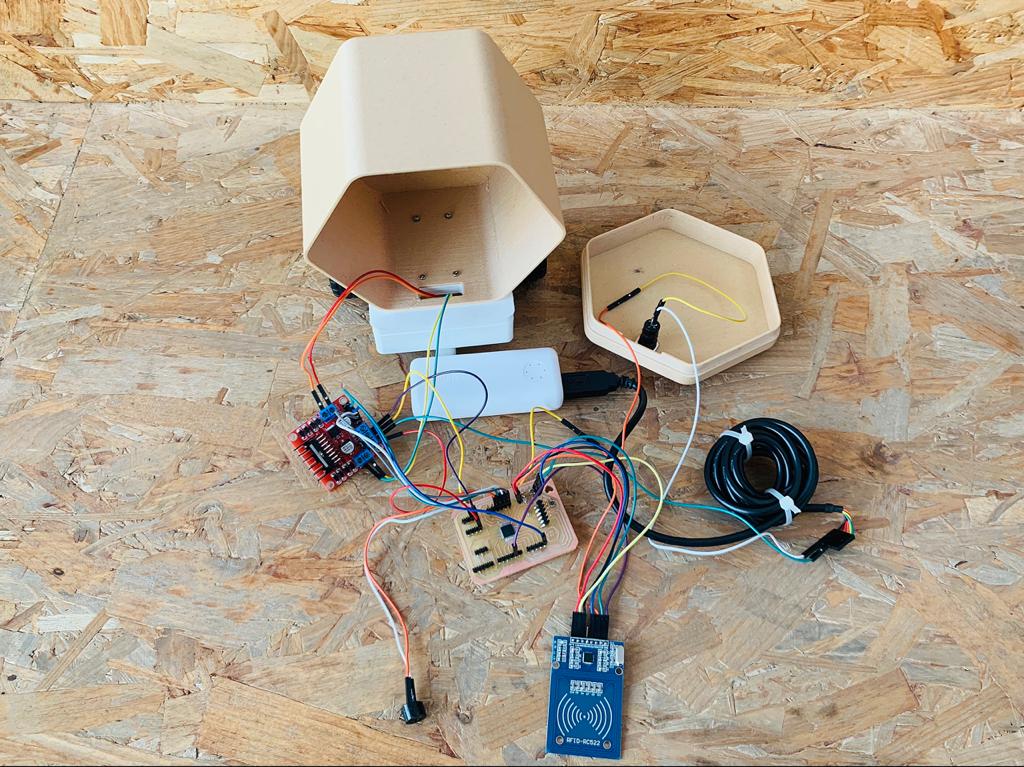

Design the robot chassis.

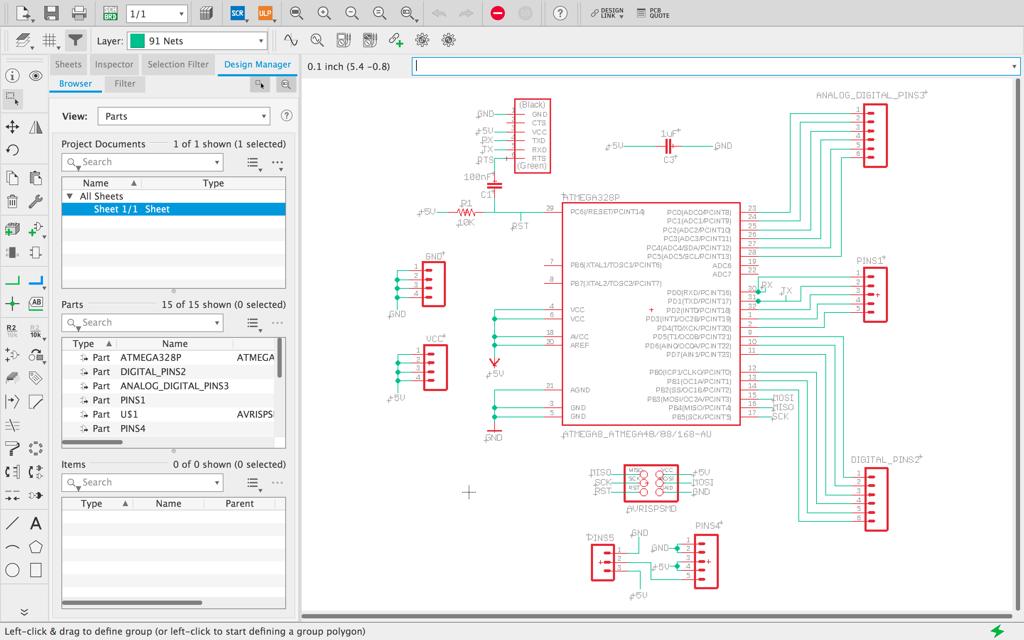

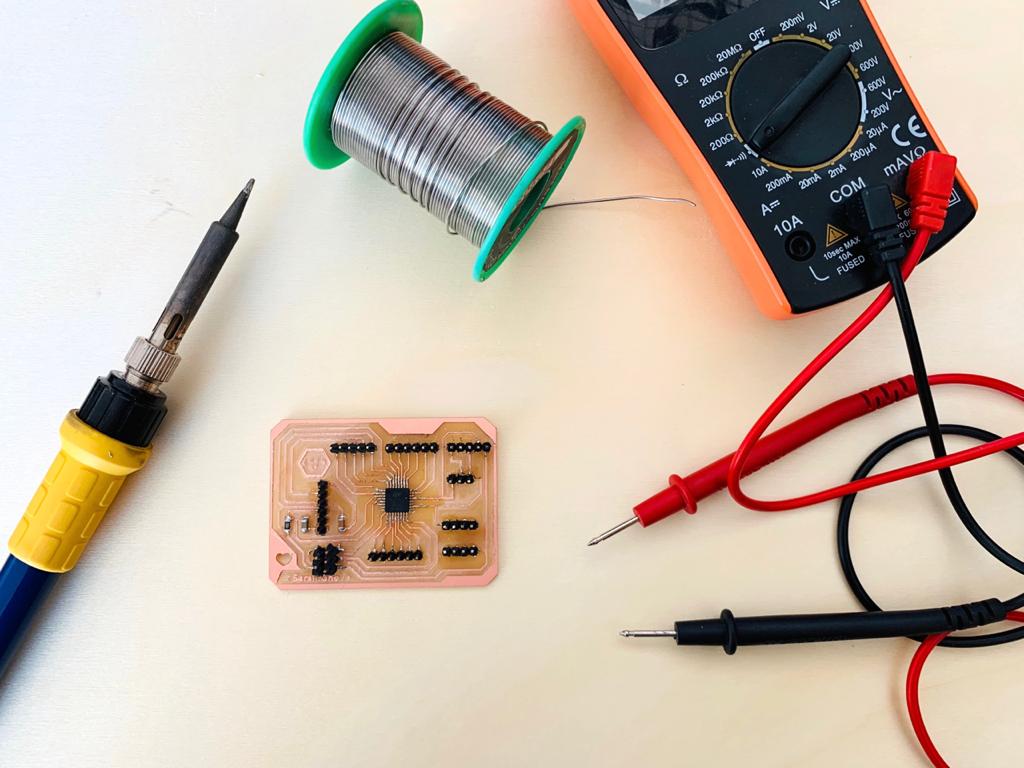

Schematic for PCB.

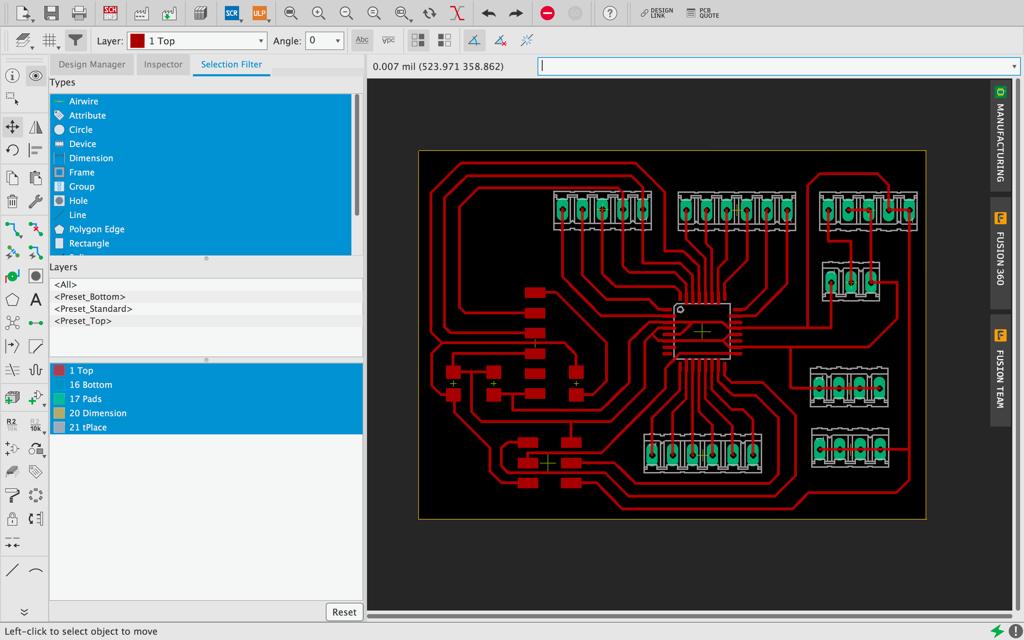

Board file for PCB.

Milled PCB.

Soldered components in PCB.

Testing the electronics parts.

REMAINING TASKS:

Complete the code.

Print 3D robot chassis.

Lasercut the blocks.

Cut the directions using the vinyl cutter.

Test the code.

Documenting the final project.

What has worked? what hasn't?

Until now, everything worked perfectly except the robot chassis. I made multiple prototypes to decide which size is suitable.

What questions need to be resolved?

Are the electronics components will insert easily inside the robot chassis ?

What type of motor shield is suitable for the robot ?

What will happen when?

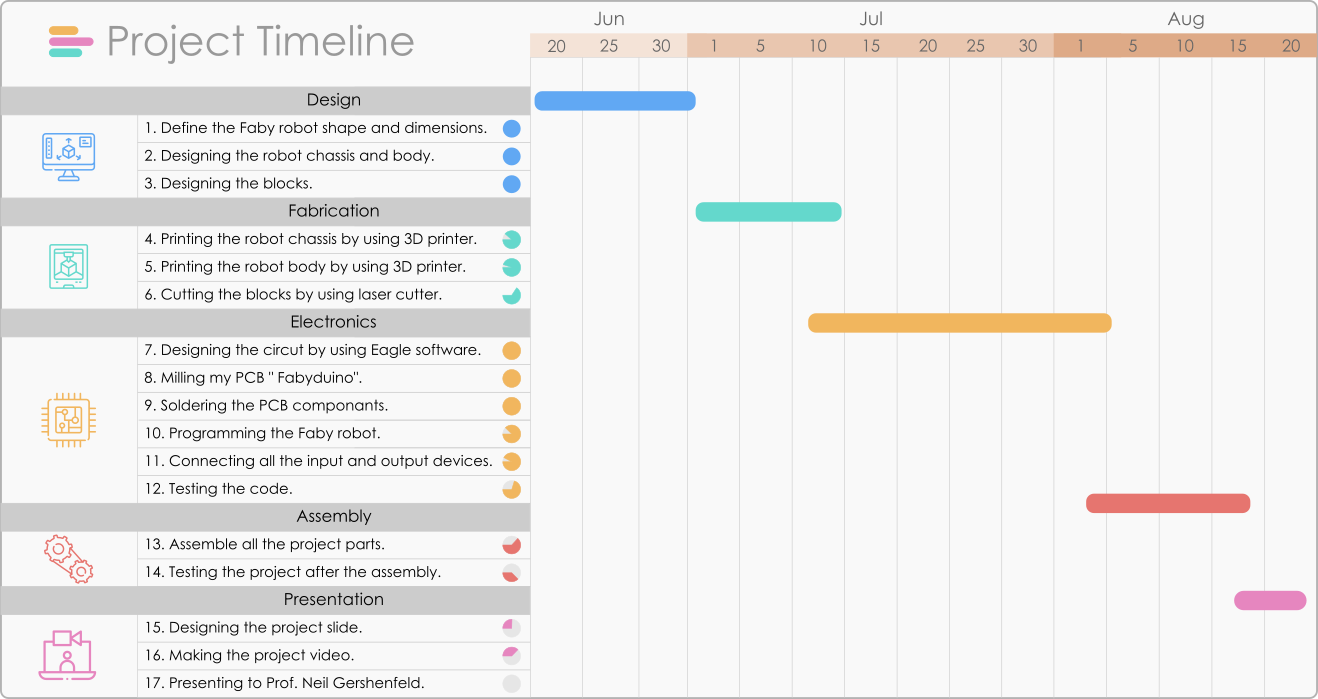

Due to the Covid-19 pandemic, I had to push the project timeline. So the plan B was to accomplish as much as possible of the part that doesn't need lab access,such as designing and documenting.

What have you learned?

A lot!

The Fab academy journey was enjoyable and an intense learning experience. I learned different manufacturing processes and techniques، especially PCB making was a new skill for me. Each week was a valuable opportunity to explore a new tool and machine. I am glad that I joined this course, it expanded my knowledge in digital fabrication. It is the best thing that happened to me in 2020 ! Now I can call myself a real Maker !

Project Management

I created a project timeline to follow that shows the progress and the deadline to each milestones and tasks.