Wildcard Week!

Week 16

Machines and Materials

Softwares

Files

During this week we have to design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, reason why I decided to esperiment with Bioplastics :D! This subject has caught my attention for a while, and even tho I did some experimentation back in uni and at the lab, It feel like there is never enought time to experiment with Bioplastics!

Individual Assigment

For the wild card week I will cast Bioplastics, even tho a lot of people has experimentes with used coffee before I want to try it myself since I have maily used gelantine in the past.

For this week assignment I started by sketching the product I was going to cast: a cup.

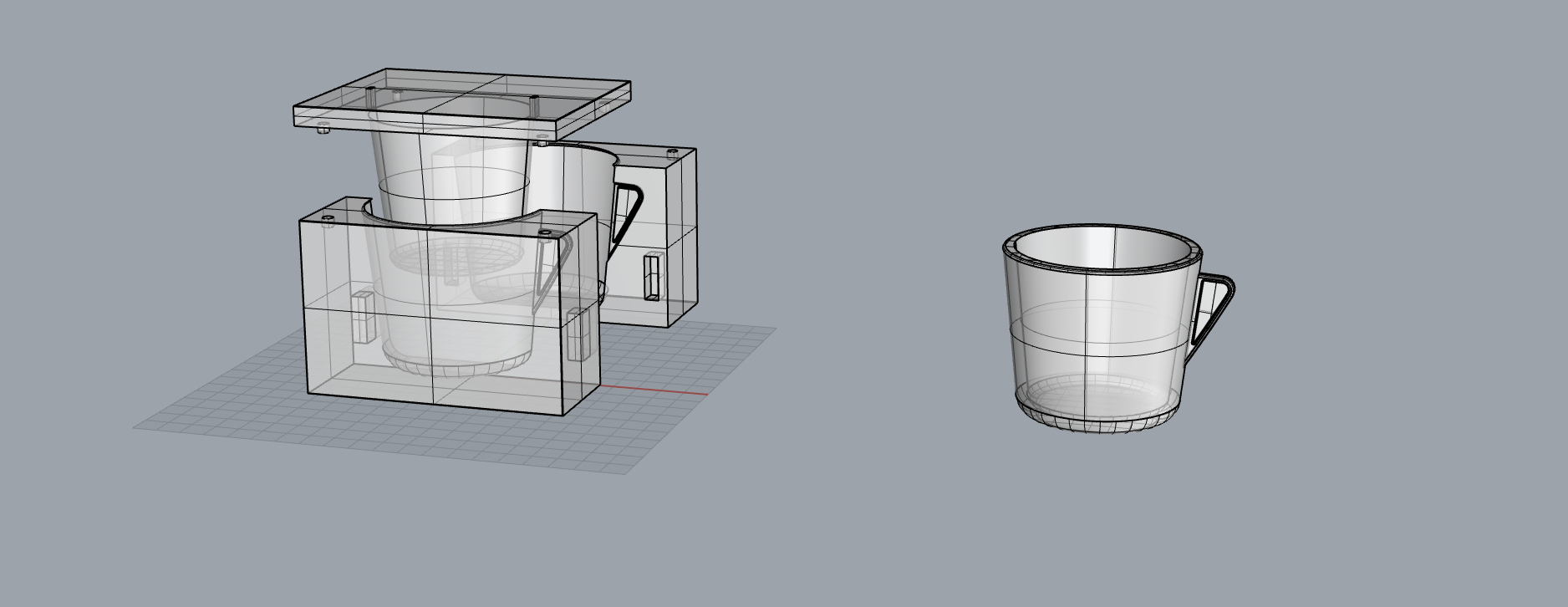

After having my design ready, it is time to 3d model it, once more, I will be using Rhino and I will be subtracting the final object (the model) from a cube (the mold) and will add the registration points and casting pipes.

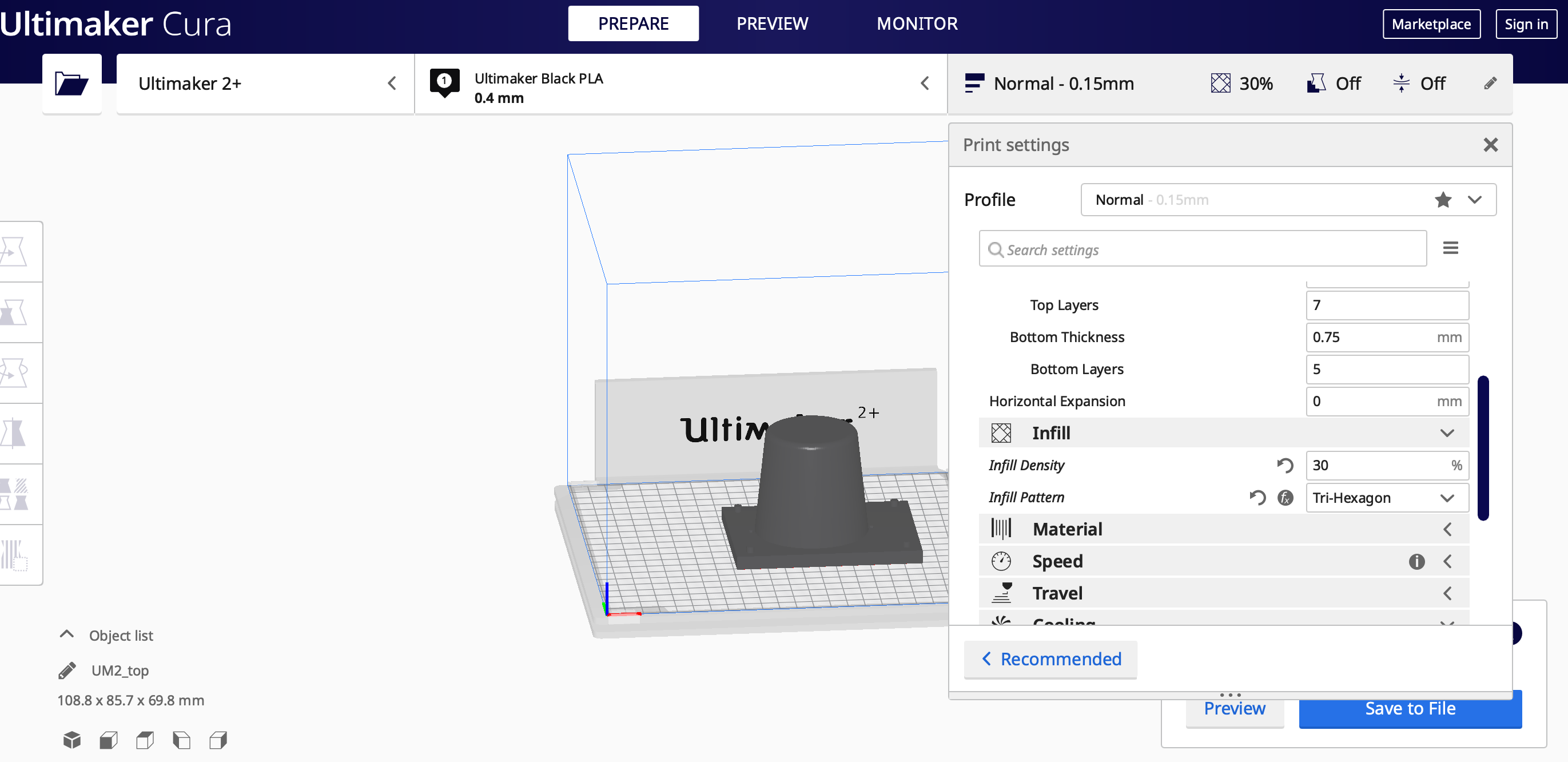

Whenver the mold is ready we have to export it to STL file, and in this case I will 3d print it, usually prefer to mill it beacuse I am not a fan of plastic (even tho PLA is recyclable) but we ran out of material and with the current situation its really hard to get it. So we drop it in Cura and set it up

While it's printing I made a quick render to try and visualize my final product

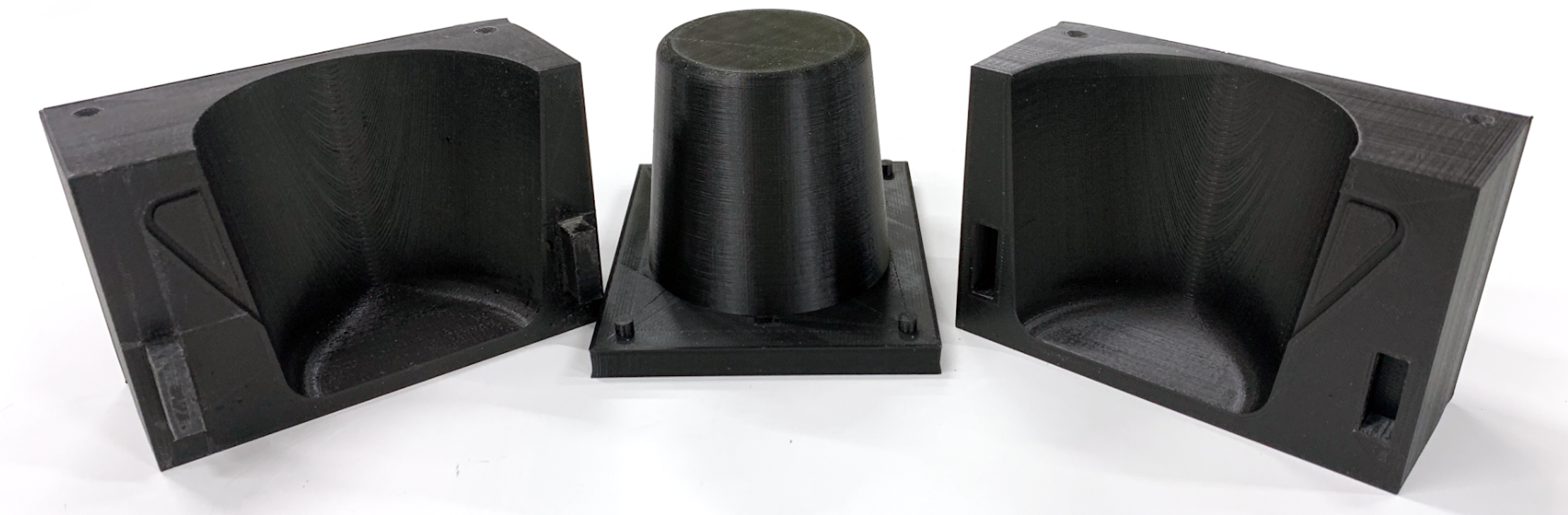

The print is finally ready and this is how the mold looks, one of the thing I could improve are the registration points, even tho they work they could be bigger and less frigile. For now I will continue with this mold.

Now its time to test some recipes, I used as a reference the followings:

- materiom.org

- Loes Bogers Recipes - Fabriacademy

- Production of Bioplastic - Matthieu Schon Pit Schwartz

Ingredients

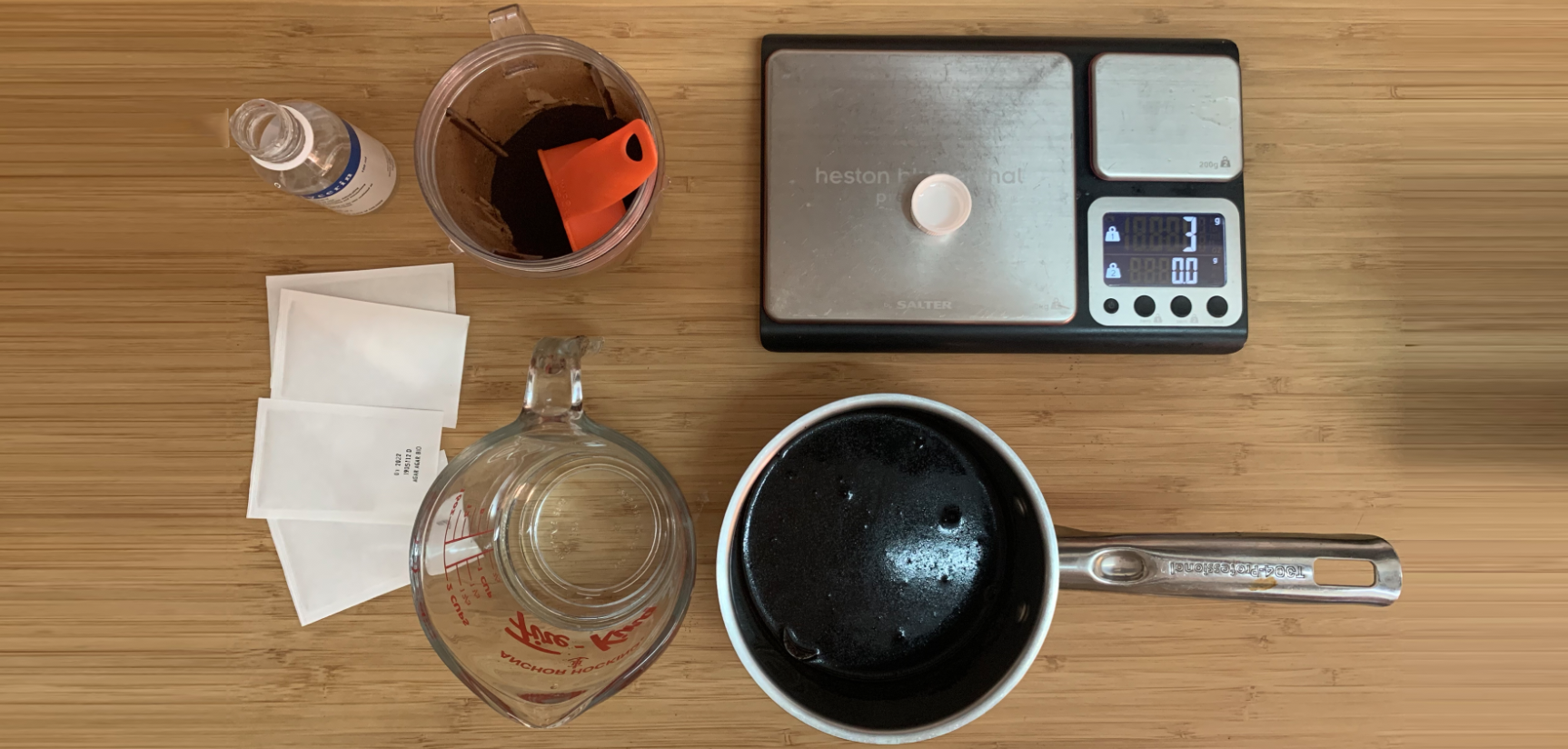

I did not have the list of ingredients listed in the recepies so I tried making my own. For the recipe, I read and did a reaserch of the most commun ingredients used in composite.

- Argan vs gelatines

Gelatin has a more jiggly, wobbly texture and agar jellies are more firm.

Agar-agar, unlike gelatin, can set at room temperature, and keeps its shape under warm temperatue which is more beneficial for this projects in particular.

- Glycerin

Glycerin makes the biolastic more flexible.

Plastics with less glycerin content made our plastic stiffer but not more breakable.

- Water

Water acts as a solvent to dissolve the starch. Secondly, it helps the starch molecules to stay disrupted after heating.

-Vinegar

Ions react with the starch polymers and make them be disordered more easily in the solution. This disorder, resulting from the disruption by the water and the ionization by the acetic acid, makes the resulting cast film more homogenous.

Recipe

- Water 125 ml

- Used coffee 1/4 cup

- Glycerin 4 gr

- Agar 8 gr

Process:

- Mix in a pan and heat it up until it is simmering.

- Pour in a mold and let it rest.

- I added some clamps to secure it.

After 2 days I took it out and it was still really wet, but we need to take it out before it dries so it does not break while shrinking.

After 1-2 more days it is completely dry,it didnt keep the shape of the mold and the size is quite different from the first day. I am still goin to try changing the recipe, maybe adding less water.